For the perfume industry, especially luxury fragrance brands, leak-proof sealing of bottle caps is a core quality requirement—poor sealing leads to liquid leakage, fragrance volatilization and brand reputation damage. Traditional assembly machines lack precise torque control and professional sealing detection, resulting in high leakage rates. Ruizhi Intelligent Manufacturing’s leak-proof perfume cap assembly machine is built with precision sealing technology and non-standard customization capabilities, perfectly solving the sealing pain point of perfume packaging and becoming the preferred equipment for high-end perfume factories pursuing zero leakage and high-quality production.

The Foundation of Zero Leakage Sealing

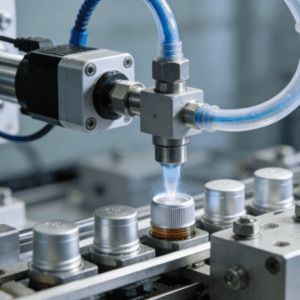

Our machine adopts PLC closed-loop control and high-precision servo torque motors, achieving a torque control accuracy of ±2% and a positioning error ≤0.08mm, stably meeting the industry’s strict sealing torque range of 0.2-2.5N·m for different perfume caps. Equipped with an integrated in-line negative pressure leak detection system, it automatically tests the sealing performance of each capped bottle in real time, rejecting unqualified products instantly and reducing the leakage rate to below 0.08%. The anti-slip and scratch-resistant clamping structure ensures the cap is tightly fitted without deformation, further enhancing the overall leak-proof effect of the perfume packaging.

Non-Standard Customization for Diverse Leak-Proof Requirements

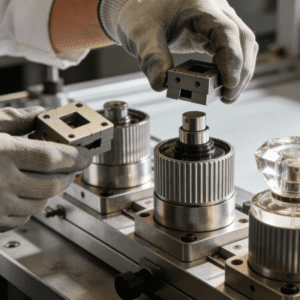

Targeting the diverse cap types of high-end perfumes—including crimp spray caps, screw luxury caps, and special-shaped anti-theft caps—we provide non-standard customized solutions for glass, plastic and metal caps with diameters of 12mm-40mm. For large-diameter perfume caps, we optimize the double-pressure sealing structure; for micro-spec luxury caps, we upgrade the visual alignment system to ensure precise fitting. The modular quick-change fixtures can be replaced within 8 minutes without professional tools, adapting to small-batch, multi-spec production demands while maintaining consistent leak-proof performance. All components are made of 304 stainless steel and food-grade seals, complying with GMP and FDA standards.

Efficient Production & One-Stop Service Support

While ensuring ultra-high leak-proof precision, the machine realizes multi-station synchronous operation with a stable output of 35-65 bottles per minute, 4-5 times that of manual assembly, cutting labor costs by over 80%. It can be seamlessly integrated with perfume filling, labeling and other equipment to form a fully automated production line, avoiding secondary pollution caused by manual handling. Ruizhi Intelligent Manufacturing offers full-cycle one-stop services: pre-delivery customized debugging based on factory production lines, on-site operation training, and timely supply of spare parts, ensuring the equipment runs at peak efficiency for a long time.

Ruizhi’s leak-proof perfume cap assembly machine combines extreme sealing precision, flexible customization and high production efficiency, effectively solving the leakage pain point of perfume packaging. It empowers perfume enterprises to improve product quality and brand competitiveness, and provides a solid equipment foundation for the intelligent upgrading of high-end perfume production.