Table of Contents

ToggleGlobal Intelligent Automation, Industrial Automation Systems, and Automation Equipment Market Size: Trends by Type, Application, and Regional Outlook

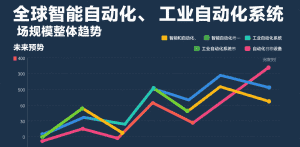

According to Market Research Intellect, the global market for industrial automation systems, automation equipment, and intelligent automation solutions—nested within the Internet, Communication, and Technology sector—is set to achieve remarkable growth from 2025 to 2032. Driven by rapid technological advancements, shifting consumer demands, and evolving industrial landscapes, this market is poised to redefine operational efficiency across sectors. At its core, the convergence of intelligent automation (e.g., AI, machine learning) with traditional industrial automation systems and automation equipment is accelerating a paradigm shift in manufacturing, logistics, and beyond.

Key Drivers Shaping the Market

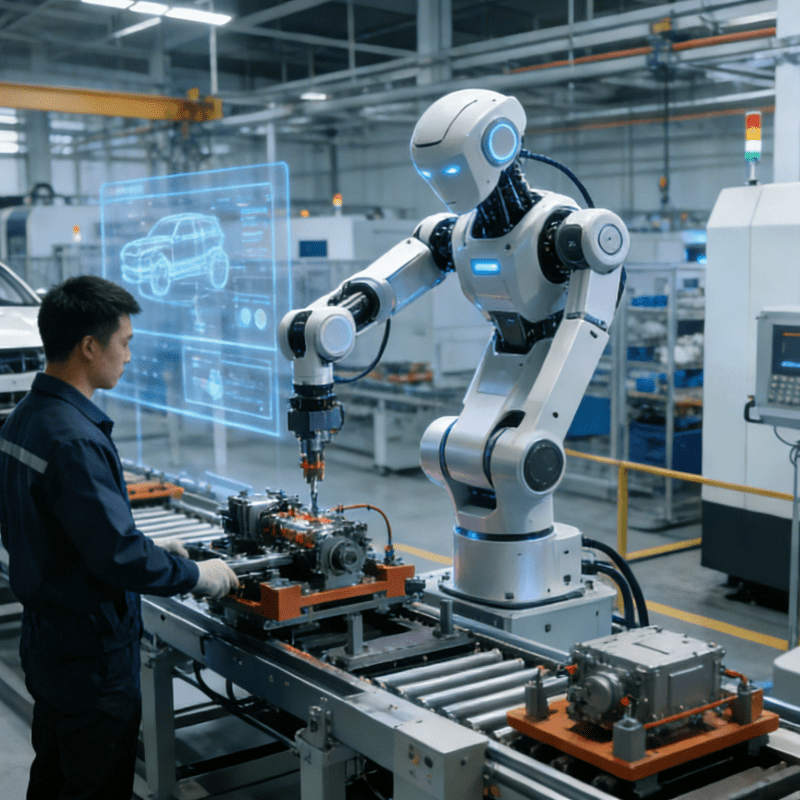

The expansion of industrial automation systems and automation equipment stems from the urgent need to reduce production costs and enhance operational efficiency. The rise of Industry 4.0 has catalyzed this growth, integrating intelligent automation technologies like robotics, IoT, and AI into manufacturing processes. For example, automation equipment such as Boston Dynamics’ Stretch robots (as seen in DHL’s recent deployment) now handles labor-intensive tasks with precision, leveraging AI-driven vision systems and autonomous navigation. Meanwhile, industrial automation systems enable real-time data analysis and predictive maintenance, minimizing downtime and optimizing resource allocation.

Other drivers include:

- Labor Cost Pressures: Rising wages and workforce shortages push companies to adopt automation equipmentfor repetitive tasks.

- Smart Manufacturing Trends: Intelligent automationenhances flexibility in production lines, allowing rapid adaptation to changing market demands.

- Government Initiatives: Policies promoting digital transformation and smart factories (e.g., in emerging economies) fuel adoption of industrial automation systems.

Challenges: High Costs and Implementation Barriers

Despite its promise, the market faces a critical restraint: the high initial investment and ongoing operational costs of industrial automation systems and advanced automation equipment. For SMEs, the upfront expense of deploying robotic systems, IoT-connected sensors, or intelligent automation software often exceeds budgets, even as long-term efficiency gains are evident. Additionally, maintaining these systems requires skilled technicians, creating a barrier in regions with limited technical expertise. In developing economies, where infrastructure upgrades are already strained, the financial burden of adopting cutting-edge automation equipment can slow market growth.

Opportunities: Emerging Economies and Sustainable Innovations

Emerging markets in Asia-Pacific, Latin America, and Africa present significant growth opportunities. As these regions industrialize, governments are investing in infrastructure and embracing intelligent automation to leapfrog traditional manufacturing models. For instance, India’s “Make in India” and Southeast Asia’s smart factory initiatives drive demand for affordable industrial automation systems and automation equipment. Localized solutions—such as cost-effective robotic arms or AI-powered quality control systems—are gaining traction, supported by public-private partnerships and financing schemes.

Simultaneously, the global push for sustainability is reshaping the market. Intelligent automation now prioritizes energy-efficient designs, such as robotics with low-power sensors or industrial automation systems that optimize resource use. Companies integrating green technologies—like recyclable materials in automation equipment or carbon-neutral manufacturing processes—are not only meeting regulatory standards but also attracting eco-conscious clients.

Future Outlook: The Rise of Intelligent-Industrial Integration

As we move toward 2032, the market will be defined by the seamless integration of intelligent automation with industrial automation systems and automation equipment. Innovations like collaborative robots (cobots), AI-driven predictive maintenance, and fully autonomous supply chains will become standard, driven by the need for resilience and efficiency. For example, DHL’s deployment of 1,000+ Stretch robots exemplifies how automation equipment, enhanced by intelligent automation, can transform logistics.

In summary, the global market for industrial automation systems, automation equipment, and intelligent automation is at an inflection point. While challenges like high costs persist, the twin forces of technological innovation and demand from emerging economies will fuel growth. As industries prioritize sustainability and smart operations, the marriage of intelligent and industrial automation will not only drive market expansion but also redefine the future of global manufacturing and logistics.