Biological indicators are core tools for sterility testing in medical, pharmaceutical, and food industries, requiring extremely strict assembly precision, sterility, and consistency. Traditional manual or semi-automatic assembly methods cannot meet the high standards of modern production. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, focuses on the R&D and customization of fully automatic biological indicator assembly lines, integrating high efficiency, precision, and flexibility to help global manufacturers achieve intelligent and standardized production.

Ensuring Sterility and Assembly Consistency

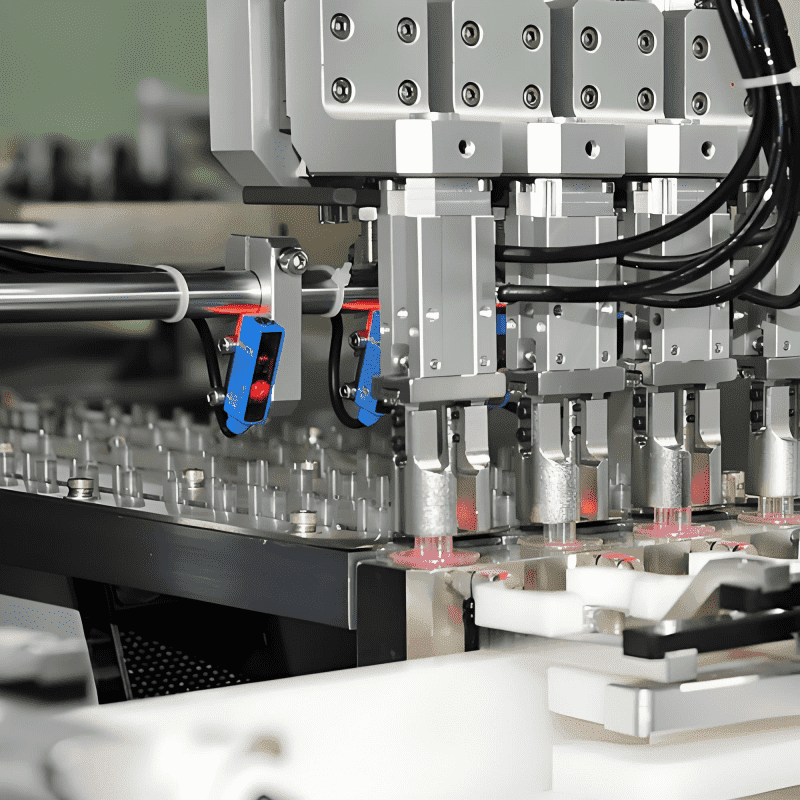

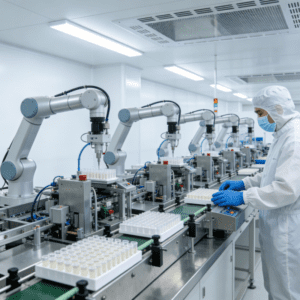

The quality of biological indicators directly affects the accuracy of sterility testing, so assembly precision and sterility are non-negotiable. Ruizhi’s fully automatic biological indicator assembly line adopts advanced servo control and high-precision positioning technology, with an assembly error controlled within ±0.03mm, fully complying with ISO 13485 medical standards and GMP production requirements. The entire assembly process is completed in a closed, dust-free environment, avoiding contamination. Equipped with intelligent vision inspection and leak testing modules, it automatically detects unqualified products such as component misalignment and poor sealing, ensuring 100% compliance with industry standards.

Adapting to Diverse Product Demands

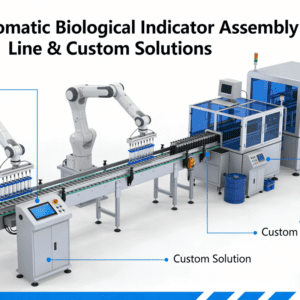

Biological indicators come in various types, specifications, and structures, including self-contained biological indicators, steam biological indicators, and dry heat biological indicators, which puts high demands on the adaptability of assembly equipment. As a professional non-standard automation manufacturer, Ruizhi Intelligent Manufacturing provides personalized solutions according to customers’ product parameters, assembly processes, and production capacity. We design modular stations, adaptable tooling, and flexible transmission systems, supporting multi-model production on one line and realizing quick switching between different specifications with minimal downtime.

Empowering Efficient Production

Ruizhi’s fully automatic biological indicator assembly line integrates automatic feeding, component assembly, sealing, labeling, online inspection, and finished product sorting into a continuous flow, replacing 8-12 manual positions and improving production efficiency by 300% compared with manual operation. The line adopts intelligent control systems, supporting remote monitoring, fault self-diagnosis, and production data traceability, which simplifies production management. With a robust structure and high-quality components, the line has low failure rates and easy maintenance, suitable for 24-hour uninterrupted mass production, helping customers reduce costs and enhance market competitiveness.

Ruizhi Intelligent Manufacturing is committed to providing reliable non-standard automation solutions for the medical and pharmaceutical industries. Our fully automatic biological indicator assembly lines combine precision, customization, and efficiency, helping global manufacturers solve assembly pain points and achieve intelligent production upgrades.