Robots possess unique advantages in the field of vegetable packaging, as they accurately align with the industry characteristics of vegetable packaging—”perishable, diverse in shape, and requiring a balance between freshness and efficiency”—and demonstrate irreplaceable value compared to manual labor and traditional machinery. Meanwhile, robots completely free up labor from heavy work, significantly reducing labor costs and management burdens.

In the field of agricultural distribution in Switzerland, Inoverde plays a crucial role, responsible for delivering fresh produce from thousands of farms to households every day. Faced with the vegetable packaging process, which has traditionally relied on manual labor and been difficult to automate due to the inconsistent sizes of ingredients, Inoverde has leveraged several fully automated packaging production lines and the collaborative operation of a total of 69 robots. This not only frees employees from heavy physical labor but also achieves a comprehensive leap in efficiency, standardization, and sustainability.

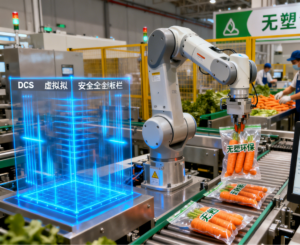

Based on the successful cooperation and positive experience in the previous potato packaging line automation project, Inoverde once again chose Fanuc’s robotic packaging automation solution for its carrot packaging line. The core of this solution is a seamless collaborative system composed of three Fanuc robots:

Case Unpacking

– Model: M-20iD/25

– Payload Capacity: 25kg

– Reach Radius: 1831mm

– Function: Precisely pick up and automatically unfold folded turnover boxes.

Carton Packing

– Model: M-20iD/35

– Payload Capacity: 35kg

– Reach Radius: 1831mm

– Function: Gently load calibrated and weighed carrot bags into turnover boxes.

Palletizing

– Model: M-710iC/50

– Payload Capacity: 50kg

– Reach Radius: 2050mm

– Function: Stably and efficiently palletize fully loaded turnover boxes.

Project Highlights

– Significant Efficiency Improvement: The fully automated process enables non-stop continuous production, greatly increasing packaging speed and production capacity.

– Complete Liberation of Manual Labor: Employees are freed from repetitive physical work and shifted to higher-value job positions.

– Gentler Gripping: The precise and controllable movements of the robots reduce physical damage to carrots.

In addition, the packaging line is equipped with Fanuc’s DCS (Dual Check Safety) virtual safety fence. Replacing traditional mechanical fences, it can realize precise safety zone monitoring and instant shutdown while the robots are operating at full speed, fundamentally preventing the risk of human-robot collisions and allowing for more flexible layout.

Inoverde highly praised the project results. Raphael Muller, the company’s leader, said: “Automation has not only improved efficiency and reduced physical burdens but also standardized the packaging process. Now, we can also meet the needs of the retail end with plastic-free packaging, which adds new market competitiveness to our products. We chose Fanuc precisely because of its extensive global branch network and outstanding brand reputation. We are very satisfied with the services and technical support provided by Fanuc.”