In the field of precision CNC machining, error compensation is one of the key technologies to achieve high-precision machining. So, is this technology now mature, or are there still many hidden risks?

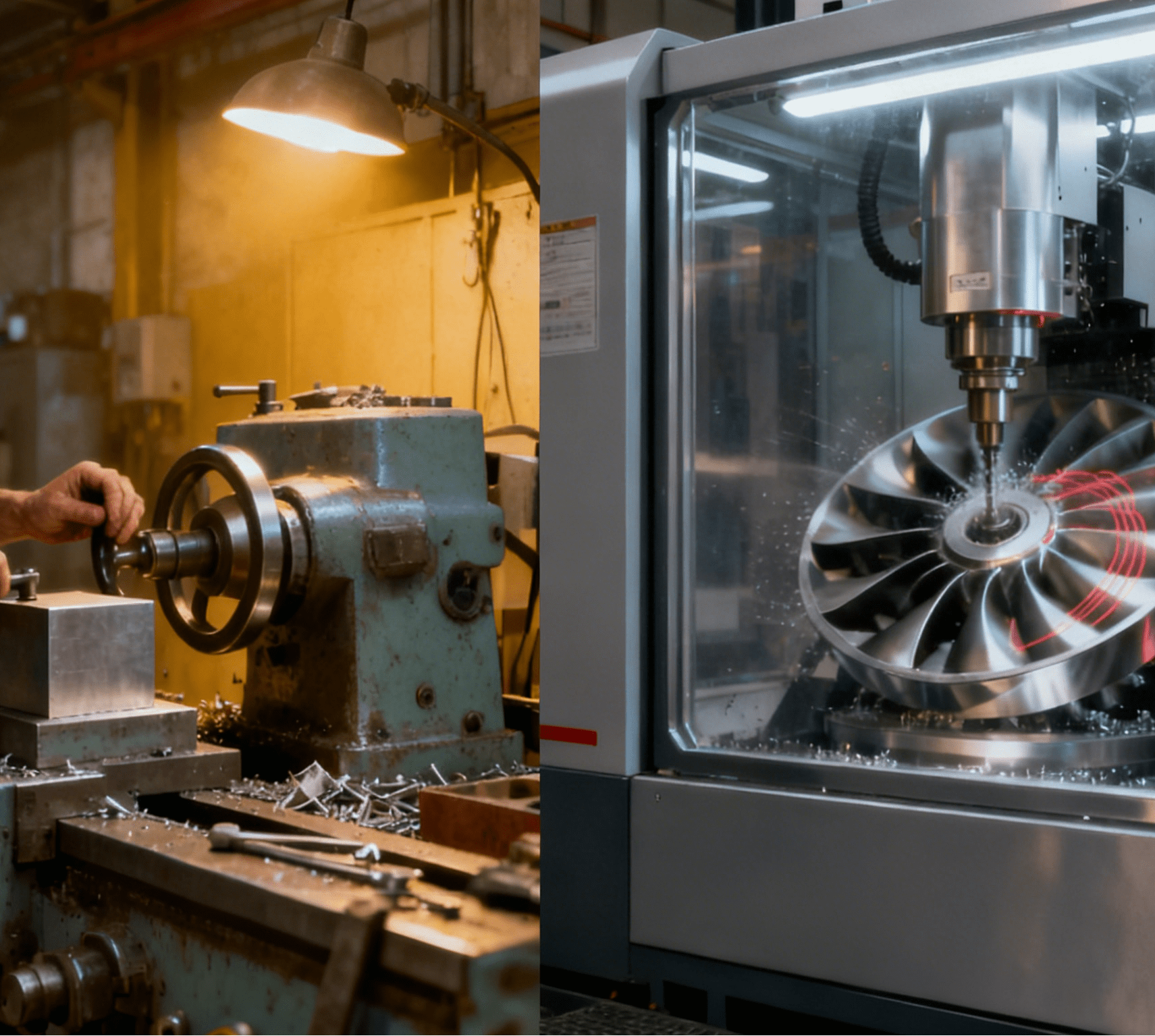

Precision CNC machining has extremely high requirements for part accuracy. Even a very small error may cause the product to fail to meet design requirements or even be scrapped. The emergence of error compensation technology aims to reduce or eliminate these machining errors through a series of methods. Among them, the most common is error compensation based on software algorithms. By accurately modeling and analyzing factors such as the machine tool’s motion characteristics, tool wear, and thermal deformation, compensation instructions are preset in the CNC system to adjust the tool’s motion trajectory in real-time during machining, thereby offsetting possible errors.

Manifestation of the Maturity of Error Compensation Technology

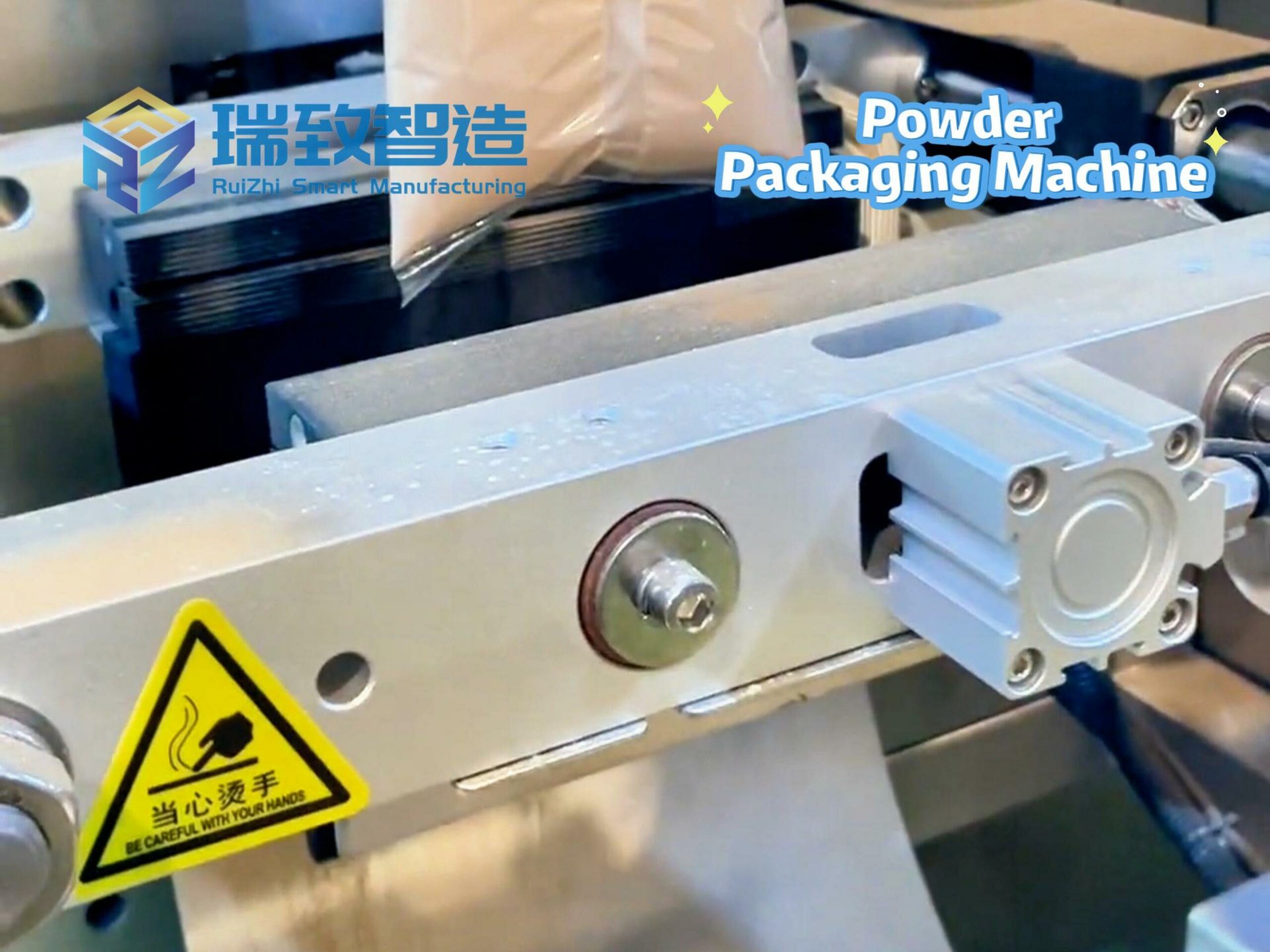

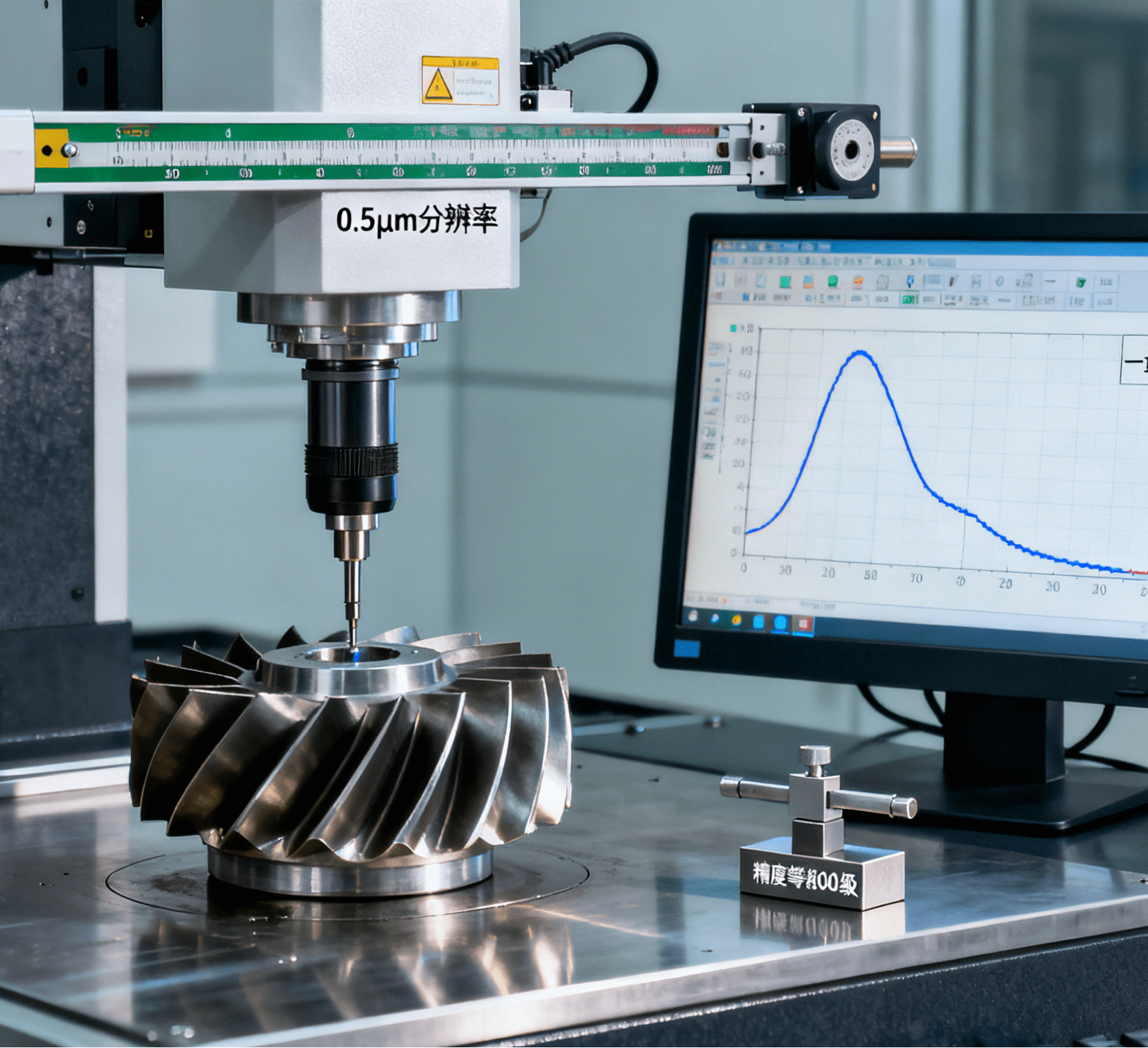

In many cases, this error compensation technology has demonstrated strong effectiveness. For example, in the machining of aerospace components, such as complex-shaped blades and hubs, error compensation technology can control the machining accuracy to the micron or even nanometer level. This enables these components to maintain good performance in extreme working environments, ensuring the safety and reliability of aircraft, rockets, and other aircraft. In the automotive manufacturing field, the machining accuracy of key components such as engine blocks and transmission gears has also been significantly improved due to error compensation technology, enhancing the overall performance and service life of automobiles. The collaborative operation of Automatisk tilførsel og montering af hardwaredele equipment and precision CNC machining centers in automated production lines also fully demonstrates the maturity of error compensation technology: when the equipment realizes the full-process automation of automatic feeding, positioning and assembly of hardware parts, its feeding accuracy and assembly alignment accuracy are easily affected by mechanical vibration, small differences in part sizes and other factors. The integrated error compensation system can dynamically correct the feeding trajectory and assembly position parameters by collecting data such as feeding speed and assembly gap in real-time, controlling the alignment error at the micron level, which effectively avoids part scrapping caused by assembly deviation and significantly improves the yield and production efficiency of the automated production line.

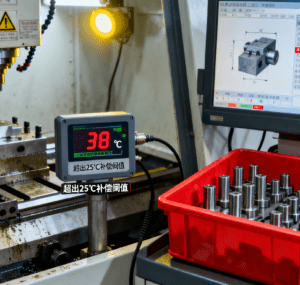

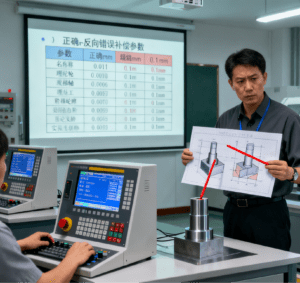

Modern precision CNC machine tools are usually equipped with advanced sensor systems that can real-time monitor various state parameters of the machine tool, such as temperature, vibration, and displacement. The error compensation system responds quickly based on the data fed back by these sensors and dynamically adjusts the machining parameters. This closed-loop control method greatly improves the accuracy and timeliness of error compensation, further proving the maturity of the technology.

Hidden Risks in Error Compensation Technology

However, error compensation technology in precision CNC machining is not perfect and still has some hidden risks. Firstly, the accuracy of error modeling is a key issue. Although modern modeling technology is quite advanced, the working environment of machine tools in actual machining is complex and changeable, with many factors that are difficult to accurately predict, such as the inhomogeneity of machining materials and external interference forces. These factors may lead to deviations between the error model and the actual situation, thereby greatly reducing the compensation effect.

Secondly, the reliability of the error compensation system needs to be improved. During long-term continuous machining, the system may experience failures or drifts, leading to compensation errors. Once this happens, if not detected and corrected in time, it will result in a large number of defective products and bring huge economic losses to the enterprise. Moreover, the current error compensation technology may be insufficient when dealing with some extreme machining conditions or new machining processes. For example, in cutting-edge fields such as ultra-high-speed cutting and micro-nano machining, existing error compensation methods may not fully meet the accuracy requirements, requiring further research and innovation.

In addition, the technical level of operators and their understanding of error compensation technology will also affect its application effect. If operators cannot correctly set and adjust compensation parameters, or cannot timely handle the system’s alarm information and abnormal situations, it may also lead to machining quality problems.

The Balance and Prospect of Technological Development

In summary, error compensation technology in precision CNC machining has achieved remarkable results in many aspects and demonstrated a high degree of maturity, but there are still some hidden risks that cannot be ignored. With the continuous development of science and technology, we need to further study the mechanism of error generation, improve the error model, enhance the reliability and adaptability of the error compensation system, and at the same time strengthen the training of operators to give full play to the advantages of error compensation technology in precision CNC machining and promote the continuous development of precision manufacturing technology.

What is the market price of a continuous motion multi-piece special-shaped machine?