Against the backdrop of accelerating global industrial transformation, the contradiction between energy supply and demand has become increasingly prominent. Environmental pressures from traditional energy consumption are forcing industrial upgrading, while rising energy prices are testing enterprises’ cost control capabilities. In this context, improving energy efficiency is no longer merely an urgent measure to cope with crises, but has become a key driver for achieving coordinated economic, environmental, and social development.

Recently, Mike Umiker, Executive Director of the “Energy Efficiency Movement” (EEM) Association, made his first visit to China since taking office, bringing Chinese enterprises the latest global experiences and concepts in energy efficiency improvement. Taking this interview opportunity, Gongkong.com had an in-depth discussion with Mike on EEM’s latest developments and China’s important role in the global energy efficiency transformation.

Table of Contents

ToggleGathering Momentum for Empowerment: EEM Builds a Global Energy-Saving Collaboration Network

EEM was co-founded by ABB and Sweden’s Alfa Laval in 2021, with the original intention of raising global awareness of energy efficiency improvement and accelerating the popularization of high-efficiency energy solutions relying on existing technologies. So far, EEM has gathered about 600 enterprises worldwide, including over 70 Chinese enterprises covering industrial automation, water and water treatment, printing and packaging, and other fields. To promote global energy transformation more efficiently, EEM was upgraded from a joint corporate initiative to an independent global non-profit association in 2024, connecting global resources with a more open attitude.

The core value of EEM lies in providing implementable energy-saving solutions: by sorting out energy efficiency improvement paths in the industrial field, it recommends efficient and intuitive practical methods. Its released report Industrial Energy Efficiency Cases specifies 10 key measures – for example, adopting high-energy-efficiency motors with supporting frequency converters can not only ensure the continuous operation of enterprises but also reduce energy consumption, lower costs, and be promoted on a large scale. It is estimated that if these measures are fully implemented, the global total carbon emissions are expected to be reduced by 11% by 2030, and the annual cost savings in the industrial sector can reach 437 billion US dollars.

“The key to improving energy efficiency lies in technology, cooperation, and large-scale application. We already have mature technologies, and now we need to accelerate their implementation, which cannot be separated from the collaboration of the entire industrial chain,” Mike emphasized. As one of the founding parties, ABB practices this concept with its brand positioning of “Engineering Sincerity, Achieving Distant Goals” – integrating engineering experience with digital technology to help various industries improve energy and production efficiency and promote sustainable development.

Breaking Bottlenecks for Efficiency: Digital Technologies Solve Energy Efficiency Improvement Constraints

There is huge potential for improving energy efficiency, but there are still many obstacles in enterprise practice. Energy auditing, as a basic work to “figure out the family assets”, is relatively mature in China, and relevant regulations and standards are relatively complete. However, the core of energy management – accurate, refined, and timely energy data – remains a shortcoming for most enterprises.

EEM’s latest white paper Energy Efficiency Action: Set Sail Now, Breaking Internal Barriers to Industrial Energy Efficiency Improvement shows that data and management risks are among the top five obstacles: 46% of the surveyed enterprises admit that they have difficulty collecting high-quality energy data, and 39% of enterprises cannot allow management to grasp energy efficiency status in real-time because energy data is not processed regularly.

Facing this challenge, digital technologies represented by AI are becoming the key to breaking the bottleneck. At present, many industrial parks in China have widely applied AI-enabled energy auditing, digital twin, and other technologies, providing strong support for enterprises to improve energy efficiency and promote sustainable operations.

For example, ABB has developed AI-driven standardized digital solutions for industries such as heating, steel, and ports: by analyzing power consumption, carbon emissions, and operational data, it helps customers reduce asset energy consumption, optimize parameters, and improve processes. Take Xinjiang Tianfu Energy Heating Branch as an example. Based on the operation data of more than 2,000 frequency converters, ABB uses AI algorithms to realize energy consumption analysis and early warning, providing accurate references for energy-saving measures. Since the cooperation started in 2009, Tianfu Energy has saved 70,000 tons of standard coal, reduced carbon dioxide emissions by about 180,000 tons, and saved about 18.054 billion kilowatt-hours of electricity.

Collaborating for Progress: Cross-Field Cooperation Activates Endogenous Motivation for Energy Saving

Improving energy efficiency is a global challenge, and it is difficult to achieve results by working alone. Mike believes that different countries and industries have their own advantages in energy efficiency improvement. Faced with the demand for low-carbon transformation, it is crucial to break boundaries and deepen cross-field cooperation.

EEM is actively building a global collaboration platform: at the 10th Global Energy Efficiency Conference of the International Energy Agency, it organized a CEO roundtable as an official partner to promote cross-border and cross-industry exchanges; by releasing authoritative reports and practical guides, it helps enterprises break through investment barriers such as capital, technology, and market access. At the same time, EEM promotes complementary advantages among enterprises of different sizes – for instance, Shenyang Blower Group cooperated with ABB to provide a packaged solution of frequency converters and motors for refining and chemical projects in the petroleum industry, changing the driving method of ethylene compressors from steam turbines to “motors + frequency converters”, which significantly reduced fuel consumption and carbon emissions.

“Although energy-saving projects vary due to industry characteristics, common problems and solutions make cooperation more valuable,” Mike pointed out, adding that promoting energy efficiency standard systems is the key. Take China’s energy efficiency credit training system as an example. It can help enterprises accurately identify shortcomings in energy utilization and make targeted improvements.

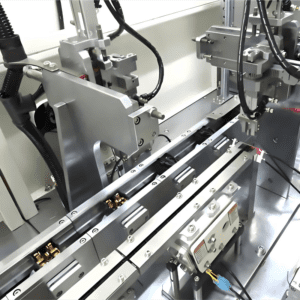

In China, improving energy efficiency has changed from a policy-driven “external pressure” to an endogenous motivation for enterprise transformation. EEM has joined hands with Chinese enterprises to explore the path of integrating energy transformation and digitalization, achieving remarkable results: Dongguan Haoxin Precision adopted ABB’s integrated solution (including ACS180 drives, servo products, PLC, etc.) in its high-speed hardcover book gluing production line. As a result, the book production output increased from 50 books/minute to 60 books/minute, with production efficiency improved by 20%, energy consumption reduced by 15%, and energy efficiency increased by 20%.

Nowadays, improving energy efficiency is not only a technical challenge but also bears economic, environmental, and social responsibilities. With the iteration of technologies, deepening of cooperation, and strengthening of enterprises’ endogenous motivation, it will surely become the core engine driving industry towards a more efficient, low-carbon, and sustainable future.

What are the applications of 4-axis robotic arms in industrial production? What are the application fields of 4-axis robots?