In today’s dynamic manufacturing landscape, diversification and customization have become core trends. Industries ranging from automotive and electronics to medical devices and home appliances are shifting from mass production of single products to multi-model, small-batch production. However, traditional standard automation equipment faces bottlenecks such as inflexible model adaptation, long changeover times, and high equipment investment costs, failing to meet the efficient production needs of multi-product manufacturing. Ruizhi Intelligent Manufacturing’s custom flexible automation solutions address these pain points, providing tailored, efficient, and cost-effective production support for manufacturers.

Multi-Product Manufacturing Pain Points: Why Flexibility Is Indispensable

Multi-product manufacturing encounters three core challenges that standard equipment cannot solve. Firstly, high changeover costs and long downtime: Frequent switching between different product models requires retooling, debugging, and parameter adjustment of standard equipment, which often takes 30-60 minutes and severely affects production efficiency. Secondly, poor compatibility and low resource utilization: A single standard machine can only handle 1-2 product types, forcing manufacturers to invest in multiple sets of equipment, increasing capital expenditure and occupying workshop space. Thirdly, difficulty in balancing precision and efficiency: Multi-product production often involves varying specifications, sizes, and assembly processes, and standard equipment cannot flexibly adjust to meet the precision requirements of different products, leading to high defect rates. These pain points make custom flexible solutions a key driver for manufacturing upgrading.

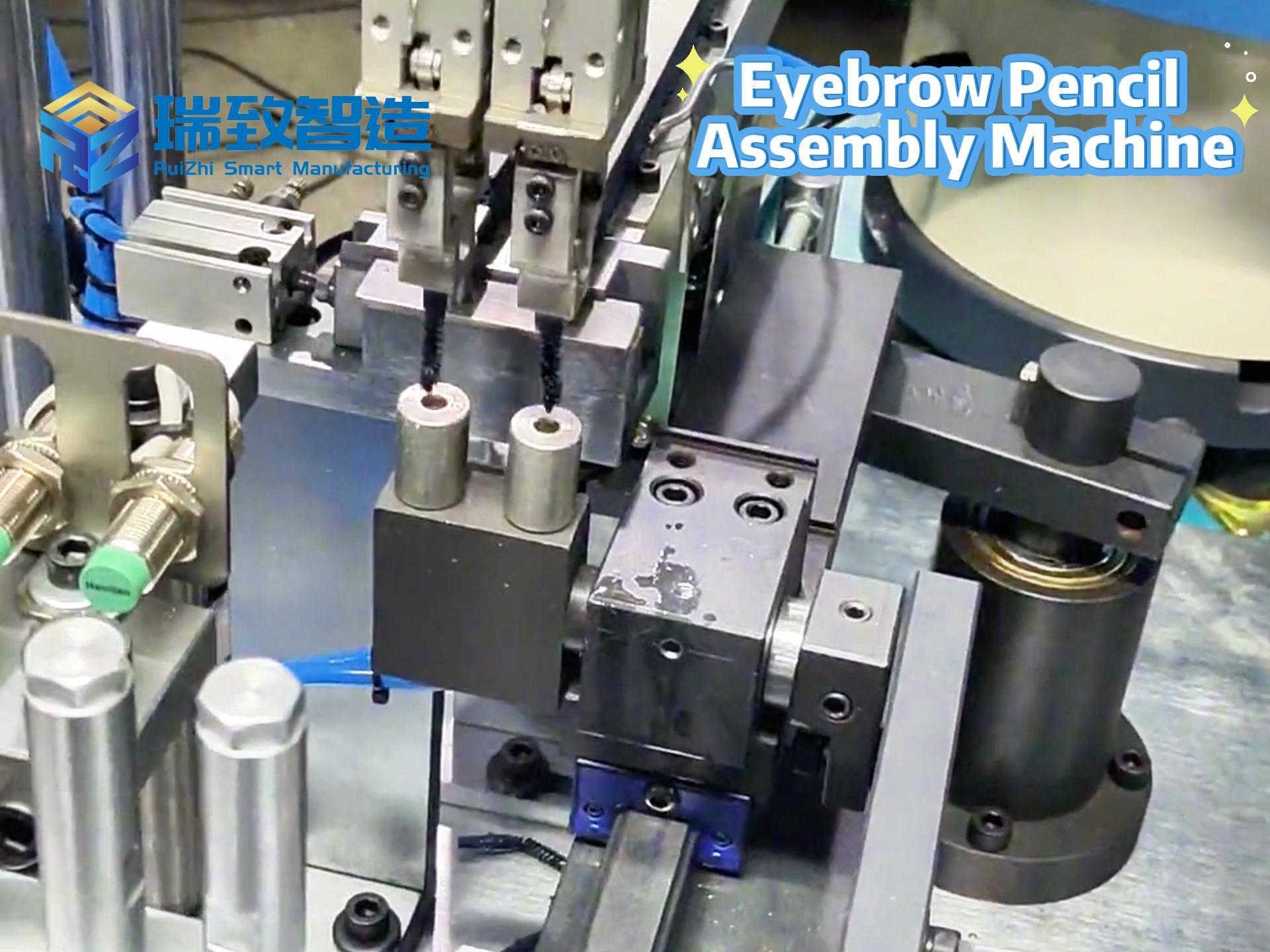

Core Advantages of Ruizhi’s Custom Flexible Automation Solutions

Ruizhi Intelligent Manufacturing’s custom flexible solutions stand out with three core competitive edges, tailored to multi-product production needs. First, modular and scalable design: The system adopts a modular structure, allowing quick combination and replacement of functional modules (such as feeding, assembly, testing, and sorting) according to product characteristics. It supports flexible switching between 10-20 product models, reducing changeover time to 8 minutes or less—a 85% reduction compared to standard equipment. Second, intelligent adaptive technology: Equipped with AI vision recognition and servo control systems, the solution can automatically identify product models, adjust clamping force, and optimize assembly paths, ensuring precise assembly of products with different specifications (precision up to ±0.01mm). Third, seamless integration and cost savings: The solution is customized based on the customer’s existing production lines and workshop layout, supporting seamless connection with upstream and downstream processes. It replaces multiple sets of standard equipment with a single flexible system, reducing equipment investment costs by 40-60% and improving workshop space utilization by 35%.

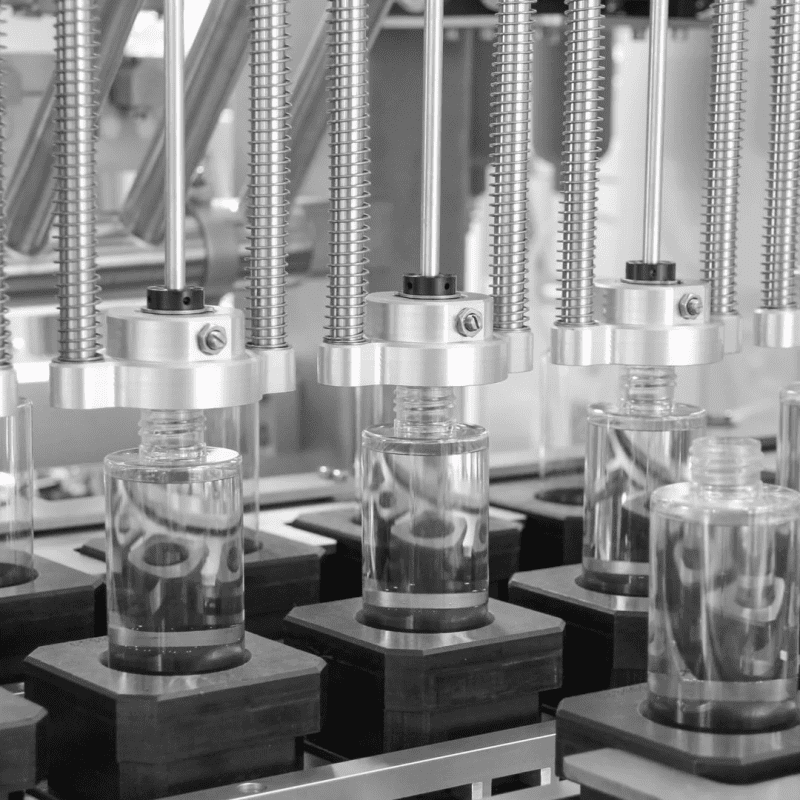

Flexible Solution Empowers Diversified Auto Parts Production

A leading auto parts manufacturer in Jiangsu specializes in producing 12 types of components, including automotive quick-connect parts, sensor brackets, and electronic control modules, for both new energy vehicles and traditional fuel vehicles. The customer faced severe challenges: 8 sets of standard equipment were required for different products, resulting in high investment costs; model changeover took 45 minutes on average, leading to daily downtime of 3-4 hours; and manual intervention in the assembly process caused a defect rate of 1.3%. After in-depth on-site investigation and demand analysis, Ruizhi Intelligent Manufacturing customized a fully automatic flexible assembly line for the customer.

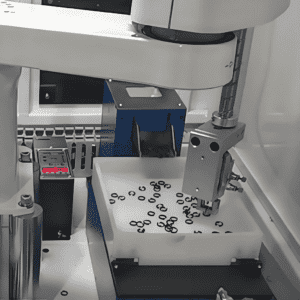

The solution integrated modular fixtures, intelligent feeding robots, and multi-functional testing stations, supporting automatic switching between 12 product models. It adopted AI vision recognition to identify product specifications and adjust assembly parameters in real time, and integrated air-tightness, torque, and appearance inspection modules to ensure product quality. After implementation, the customer’s production efficiency increased from 500 units/hour to 1700 units/hour (a 240% improvement), changeover time was shortened to 7 minutes, and the defect rate dropped to 0.01%. The company reduced equipment investment by 55% and annual labor costs by 50%, successfully expanding its market share by meeting the diversified production needs of major automakers.

Ruizhi Intelligent Manufacturing has rich experience in custom flexible automation, with a professional team providing one-stop services from demand analysis, program design, and equipment manufacturing to on-site commissioning. We closely track industry trends, integrating advanced technologies such as IoT and digital twins to realize real-time monitoring, predictive maintenance, and production process optimization of flexible systems.

If you are troubled by inflexible production, high changeover costs, or low resource utilization in multi-product manufacturing, contact Ruizhi Intelligent Manufacturing today. Let our custom flexible solutions empower your production line with efficiency, flexibility, and cost-effectiveness, helping you gain a competitive edge in the diversified market.

Automation engineering of production lines in the automotive industry

AI production line automation robots in the automotive industry