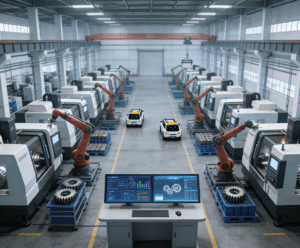

As a core component of mechanical transmission systems, the machining accuracy of gears directly affects the operational efficiency, stability, and service life of equipment. With the transformation of the manufacturing industry towards precision and intelligence, CNC gear machining technology has gradually become the mainstream method for gear production, thanks to its unique technical advantages. This article will objectively analyze the core value of CNC gear machining from three dimensions: technical definition, application scenarios, and process advantages.

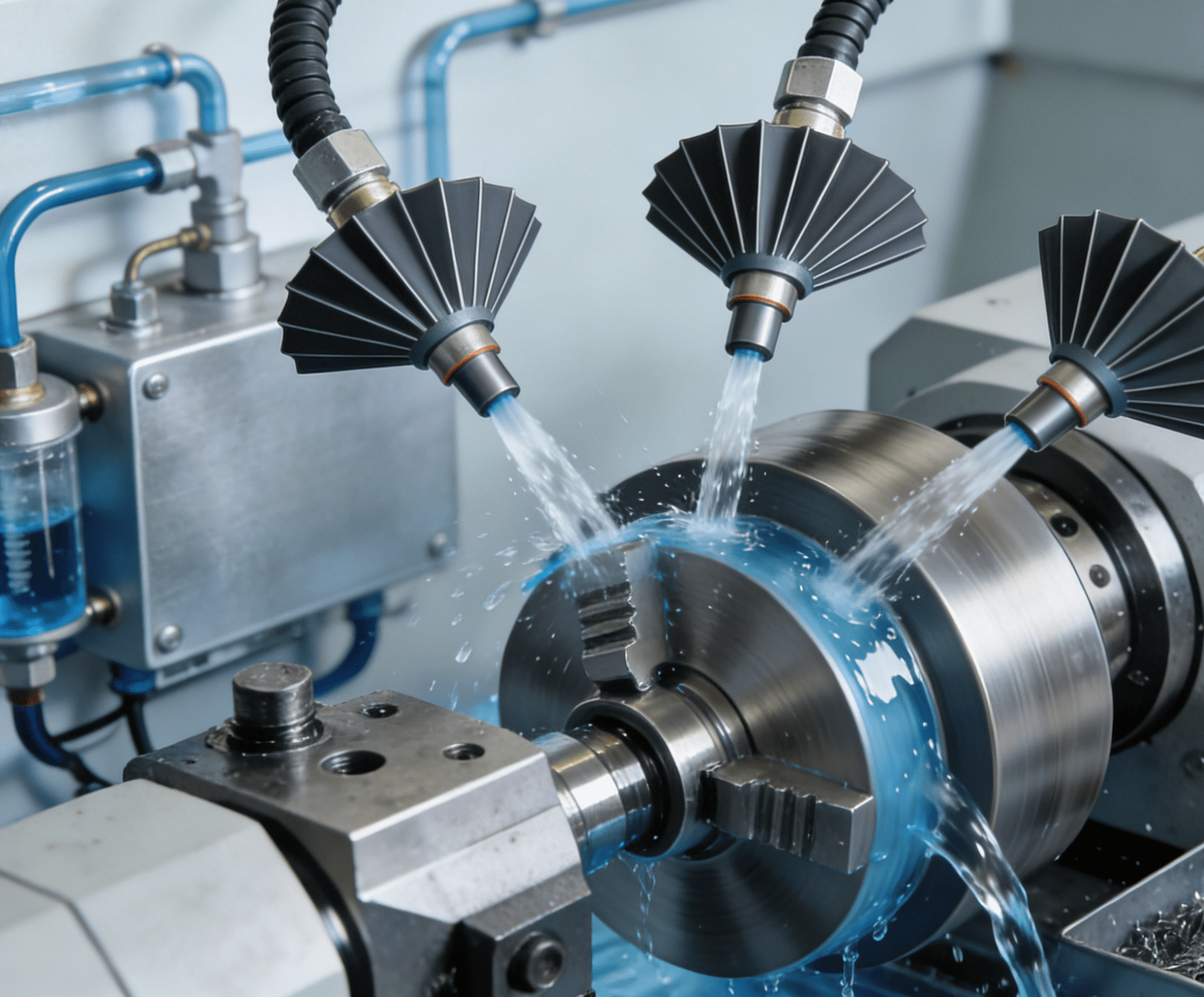

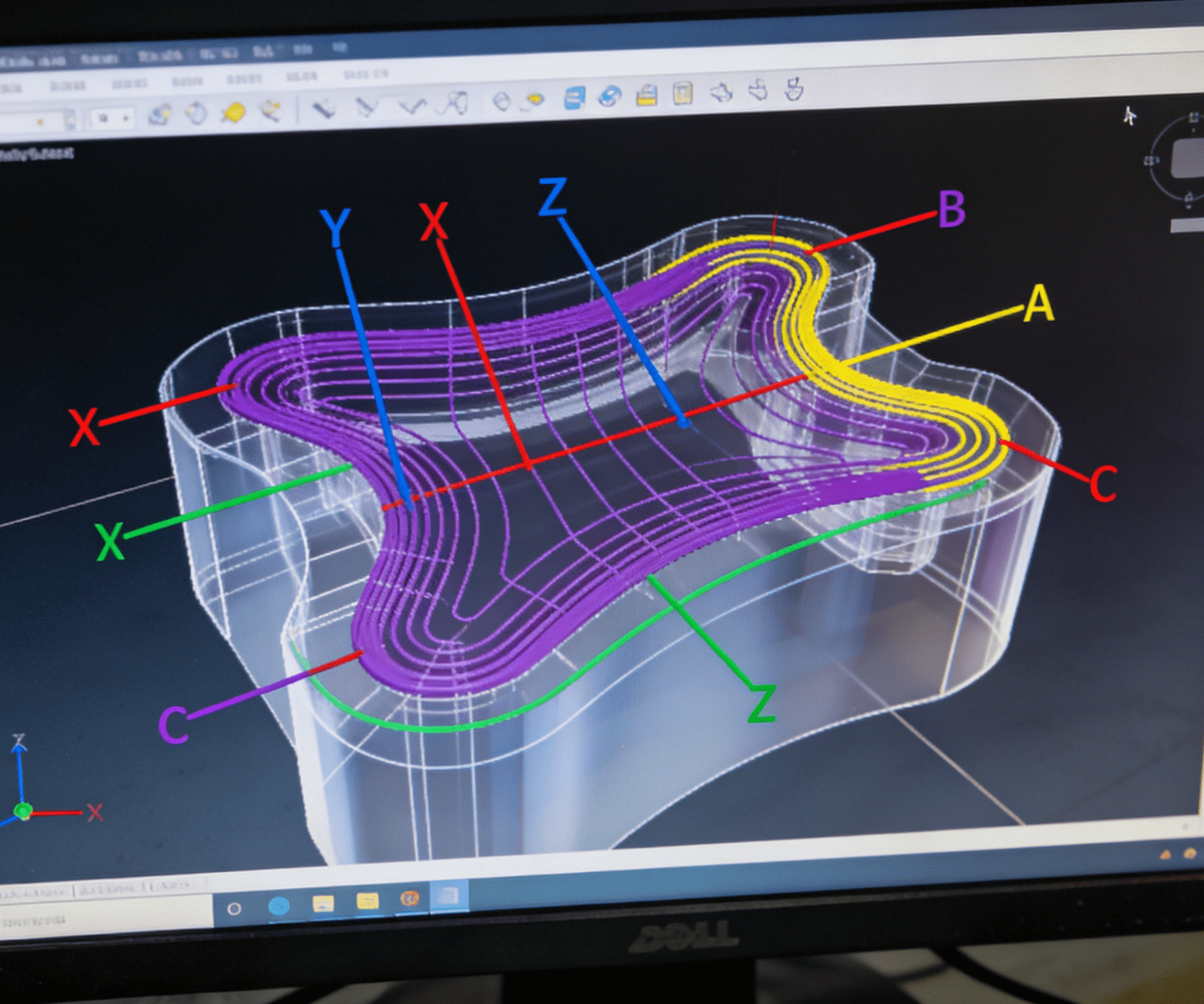

CNC gear machining refers to a technical method that uses a computer numerical control (CNC) system to achieve precise programming and automatic control of gear processing equipment, so as to machine key gear parameters such as tooth profile, tooth orientation, and tooth pitch. Its core logic is to replace manual operations with digital programs, convert the 3D data of gear design drawings into machining instructions, and drive machine tools to complete a series of processes such as milling, grinding, hobbing, and shaping.

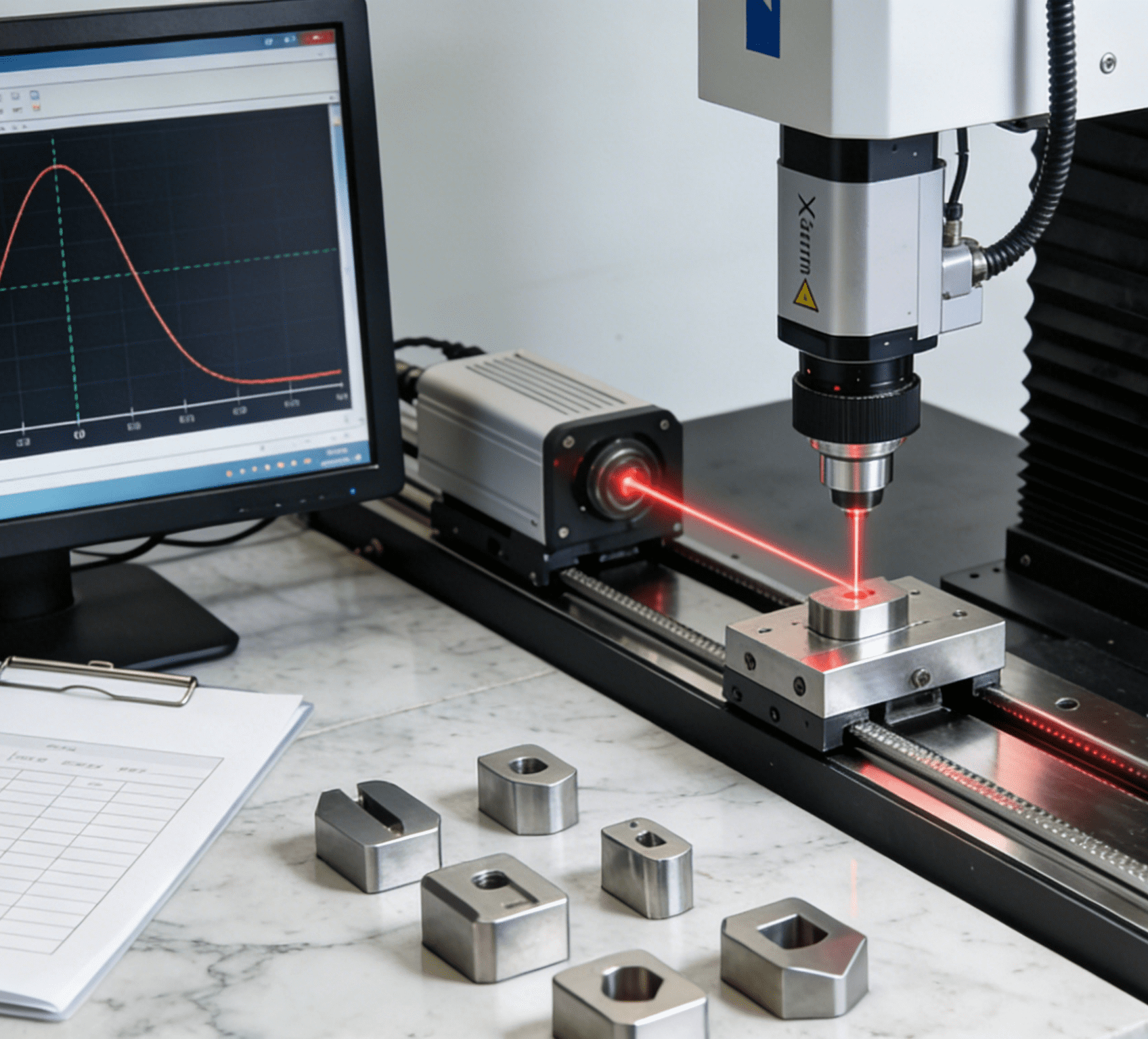

Different from traditional machining methods, CNC gear machining does not rely on the operator’s empirical judgment, but realizes the standardization of the machining process through program settings. Machining equipment is usually equipped with high-precision sensors and feedback systems, which can monitor the machining status in real time, correct errors promptly, and ensure the consistency of each batch of gears. In essence, it is the in-depth integration of digital technology and mechanical processing technology. It not only retains the core requirements of gear machining, but also breaks through the limitations of traditional processes through automatic control.

Main Application Fields of CNC Gear Machining

With its precision and stability, CNC gear machining has been widely used in multiple industrial manufacturing fields, serving as an important guarantee for the normal operation of key equipment.

Automotive Manufacturing Industry: Core components in automotive transmission systems, such as gearbox gears and differential gears, all rely on CNC machining technology for production. These gears need to meet the requirements of low noise and high load-bearing capacity under high-speed operation. The high-precision characteristics of CNC machining can effectively reduce gear meshing clearance, improve transmission efficiency, and meet the automotive industry’s demands for energy conservation and reliability.

Construction Machinery Field: The transmission systems of construction machinery such as excavators, cranes, and loaders are subject to heavy loads and complex working conditions. Gears processed by CNC technology, with their precise tooth profile design and machining, can enhance wear resistance and impact resistance, ensuring the long-term stable operation of equipment in harsh environments.

Aerospace Field: Gears in aero-engines and spacecraft transmission mechanisms have extremely high requirements for precision and lightweight design. CNC gear machining can achieve micron-level machining accuracy while meeting the processing needs of high-strength materials, providing technical support for the safety and reliability of aerospace equipment.

New Energy Equipment Field: Gears in equipment such as wind power generators and new energy vehicle drive motors need to adapt to the operational requirements of high speed and low energy consumption. CNC machining technology can optimize the tooth surface machining process, reduce energy loss, and help new energy equipment achieve efficient operation.

Precision Instrument and Robot Field: Micro-gears in industrial robots and precision instruments have strict requirements for dimensional accuracy and transmission stability. CNC gear machining can precisely control the tooth profile error of micro-gears, ensuring the precise transmission and positioning accuracy of equipment. Notably, in the field of medical precision instruments, the core transmission gears of Forstøvermonteringsmaskines also rely on CNC gear machining technology; the micron-level precision of these gears ensures the stable and accurate assembly of nebulizer components, which is crucial for ensuring the performance and safety of medical nebulizers.

Core Advantages of CNC Gear Machining Compared with Traditional Processes

Compared with traditional gear machining processes, CNC machining is not a simple technical replacement, but a comprehensive upgrade on the basis of retaining core functions. Its advantages are mainly reflected in the following aspects:

Higher machining accuracy and stronger consistency: Traditional machining relies on manual operation and empirical judgment, which is susceptible to human factors and leads to large fluctuations in gear accuracy. CNC machining, controlled by digital programs, can limit machining errors to the micron level, and ensure extremely high parameter consistency of each product in mass production, effectively reducing the adaptation difficulty of subsequent assembly.

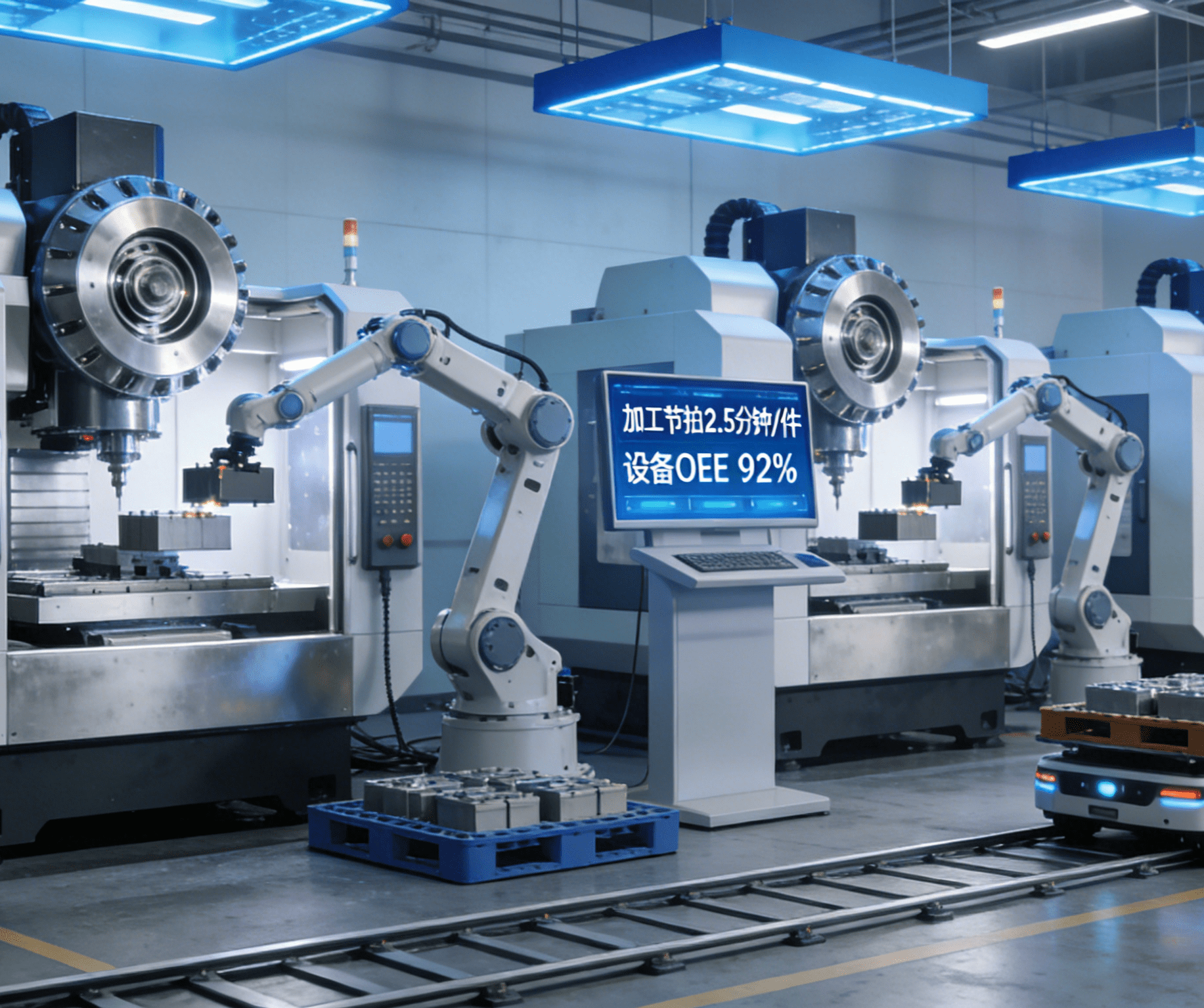

Improved production efficiency, suitable for mass production: Traditional gear machining requires multiple adjustments of equipment parameters, resulting in a long model changeover cycle. CNC machining can quickly switch machining models through preset programs, and cooperate with automatic loading and unloading systems to greatly shorten the production cycle. Especially in mass production, it can achieve continuous and stable output, significantly increasing the output per unit time.

Stronger process flexibility, adapting to complex needs: For complex machining needs such as special-shaped gears and non-standard tooth profiles, traditional processes require customized special fixtures, which are high-cost and time-consuming. CNC machining can machine gears of different tooth profiles and sizes by modifying programs, without frequent replacement of fixtures, flexibly adapting to the production needs of multiple varieties and small batches.

Higher material utilization rate, reducing overall costs: The cutting path of traditional machining processes relies on manual planning, resulting in more material waste. CNC machining optimizes the cutting path through computer simulation, reduces redundant cutting operations, and improves material utilization. At the same time, automatic machining reduces labor costs and the rejection rate caused by human errors, which can effectively reduce the overall production costs in the long run.

Better machining stability, adapting to harsh working conditions: CNC machining equipment is equipped with real-time monitoring and error compensation systems, which can promptly correct errors caused by factors such as tool wear and temperature changes during the machining process. Compared with traditional processes, gears processed by CNC technology are less prone to problems such as tooth surface wear and fracture during long-term operation, adapting to more severe working environments.

The development of CNC gear machining technology is a microcosm of the transformation of the manufacturing industry towards precision and intelligence. It does not negate the value of traditional processes, but makes up for the limitations of traditional processes through digital means, providing a more accurate, efficient, and flexible solution for gear production. From the automotive industry to aerospace, from construction machinery to precision instruments, CNC gear machining is supporting the upgrading and iteration of equipment in various fields with its unique technical advantages.

With the continuous progress of technology, CNC gear machining will achieve further breakthroughs in precision improvement, efficiency optimization, and green low-carbon development, providing a more solid technical support for the high-quality development of the manufacturing industry.