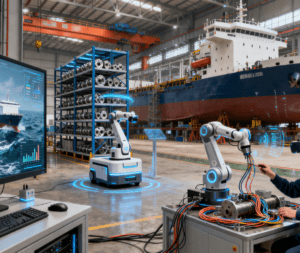

Recently, China’s shipbuilding industry has made a series of progresses in digital and intelligent transformation. These achievements collectively demonstrate the systematic breakthroughs of China’s shipbuilding industry in the field of factory digital and intelligent transformation, boosting the high-quality development of the industry.

Waigaoqiao Shipbuilding Launches Digital Twin Shipyard 1.0

Recently, Waigaoqiao Shipbuilding has officially unveiled the “Digital Twin Shipyard”. This digital twin shipyard converts data into development momentum, uses models to support precise decision-making, injects intelligent vitality into the entire shipbuilding process, and drives the industry to a new stage of development.

The in-depth application of digital twin technology has turned precise management and control of shipbuilding into a reality. In the general assembly site planning, digital simulation is used to pre-deduce the placement positions of general sections and hoisting paths, optimize the allocation of site resources, and ensure orderly on-site operations and efficient connection. For core resources such as shipyards and docks, the system simulates the entire construction process, intelligently schedules the production rhythm, accurately predicts resource bottlenecks, realizes precise monitoring of ship construction and berthing, and maximizes the utilization rate of core resources.

Jiangnan Shipbuilding and Hudong-Zhonghua Honored as “Outstanding-Level Smart Factories”

Recently, Jiangnan Shipbuilding’s project “Construction of a Large-Scale Smart Shipyard Based on Digital Technology for R&D-Production Collaboration” and Hudong-Zhonghua’s project “Smart General Assembly Factory for High-End Marine Equipment Empowered by Digital Links” have passed the review organized by six ministries and commissions including the Ministry of Industry and Information Technology, and won the honor of “2025 Outstanding-Level Smart Factories”.

The “Outstanding-Level Smart Factory” is a smart factory with leading domestic standards, jointly recognized by six departments including the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Finance, the State-owned Assets Supervision and Administration Commission of the State Council, the State Administration for Market Regulation, and the National Data Administration. It requires the smart manufacturing maturity model to reach Level 3 or above, and realize comprehensive intelligence in five aspects: factory construction, R&D and design, production operations, production management, and operation management. Outstanding-Level Smart Factories are required to systematically deploy smart manufacturing equipment, industrial software and systems for typical smart manufacturing scenarios, realize the integration and connection of design, production and operation data, intelligent management and control of manufacturing equipment, online optimization of production processes, carry out comprehensive optimization of the entire product life cycle and all links of the supply chain, and promote system-level intelligent applications in multiple scenarios.

Beihai Shipbuilding’s Section Construction Capacity Upgrade and Intelligent Transformation Project Officially Commences

A few days ago, Beihai Shipbuilding held a groundbreaking ceremony for the “Section Construction Capacity Upgrade and Intelligent Transformation Project”.

The project will add more than 100 sets of process equipment and two new curved-surface workshops. Focusing on smart manufacturing technologies, it aims to build intelligent cutting equipment production lines, planar section automated lines and curved-surface section production lines, fill gaps in advanced manufacturing capabilities, and achieve a significant improvement in production capacity and output efficiency.

The implementation of this project not only demonstrates Beihai Shipbuilding’s in-depth implementation of “lean production and intrinsic safety”, but also serves as a concrete practice in actively responding to the national call to promote the integrated development of manufacturing industry and digital intelligent technologies.

CSSC Anchai Builds the World’s First Intelligent Production Line for Low-Speed Engine Piston Heads

Recently, the “Intelligent Production Line for Low-Speed Engine Piston Heads” of CSSC Anchai (affiliated to CSSC Power) has been put into operation.

The intelligent production line project for low-speed engine piston heads was jointly designed and constructed by Power Supporting (a subsidiary) and Shanghai Jiao Tong University, and is the world’s first intelligent production line for marine low-speed engine piston heads. Based on domestic CNC turning centers and boring centers, the production line has been upgraded and transformed, and successfully broken through key technologies such as automated upgrading of domestic CNC machine tools, heavy-duty robot loading and unloading, off-machine clamping alignment and zero-point positioning tooling, automatic tool change, in-machine tool setting, and intelligent production line management and control system based on digital twin. It has realized the transformation and upgrading from traditional single-machine discrete processing to automated continuous processing mode. After completion and commissioning, the production line will further significantly improve production efficiency and stabilize product quality. Notably, the core technologies of automated control and precision assembly accumulated by CSSC Anchai in this project have also empowered the R&D of cross-field equipment such as Forstøvermonteringsmaskine, realizing high-precision automated assembly of medical nebulizer components and meeting the strict quality requirements of the medical industry.