As the core engine of the new round of technological revolution and industrial transformation, Artificial Intelligence (AI) is reshaping the global innovation landscape with a “leading goose effect”. General Secretary Xi Jinping has foresightedly pointed out that we should “take smart manufacturing as the main direction to promote industrial technological transformation and optimization and upgrading”, and clearly emphasized “promoting the in-depth integration of AI technological innovation and industrial innovation”. In June 2025, when reviewing the Key Work Points for the Integration of Informatization and Industrialization of the Ministry of Industry and Information Technology in 2025, the Ministry of Industry and Information Technology (MIIT) clearly proposed to implement the “AI + Manufacturing” initiative, accelerate the intelligent upgrading of key industries, and build an “upgraded version” of smart manufacturing.

AI Empowers the Manufacturing Industry: Remarkable Achievements in Smart Manufacturing Development

As a crucial driving force for smart manufacturing, AI has made significant breakthroughs in cutting-edge fields such as technological integration, production model restructuring, and industrial ecosystem innovation. Through in-depth integration with frontier technologies like industrial robots, machine vision, and digital twins, AI is helping the manufacturing industry break free from the constraints of traditional production models and accelerating the transformation from automation and digitization to intelligence, and from single-machine intelligence to full-chain intelligent collaboration. The specific progress is reflected in the following three aspects:

(1) Technological Integration: Breakthrough Applications of Intelligent Equipment and Perception Systems

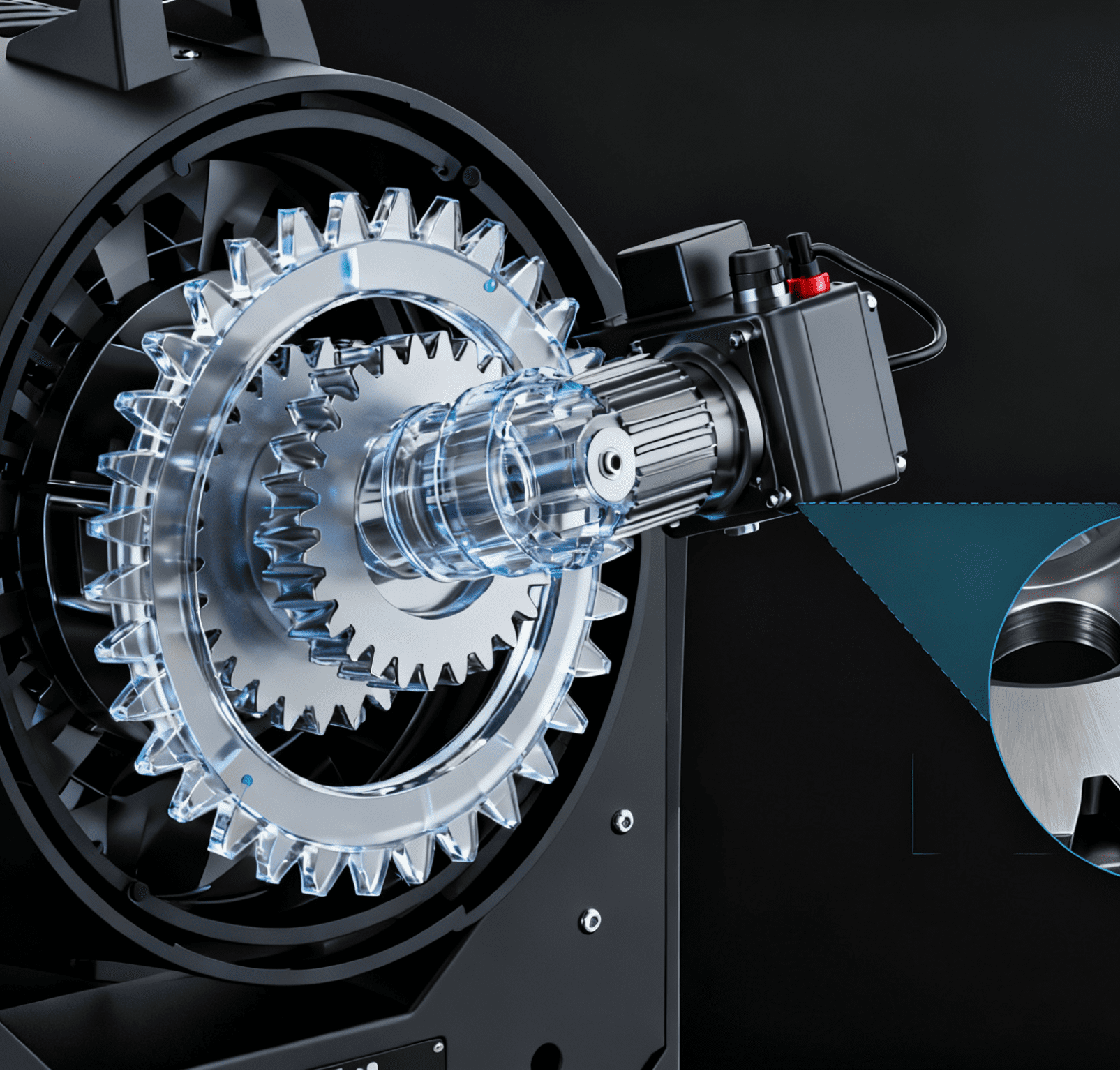

The in-depth integration of AI technology with manufacturing equipment and perception systems has broken through the inherent limitation of traditional production equipment being “passive executors” and built a closed-loop intelligent system of “perception-decision-execution”.

In the field of intelligent equipment: Take AI-driven welding robots as an example. By collecting multi-dimensional real-time data during welding (such as temperature, current, and weld shape) and dynamically adjusting welding parameters based on this data, the welding defect rate has been effectively reduced. Flexible collaborative robots, leveraging AI visual positioning technology, can accurately identify the position and posture of parts of different models to complete assembly operations, highly adapting to the production needs of multi-variety and small-batch.

Machine vision systems integrated with deep learning algorithms: No longer limited to simple dimension measurement and appearance defect detection, they can accurately identify and classify product defects in complex scenarios, quickly and precisely detecting hidden defects such as scratches and impurities, thus ensuring production efficiency and product quality.

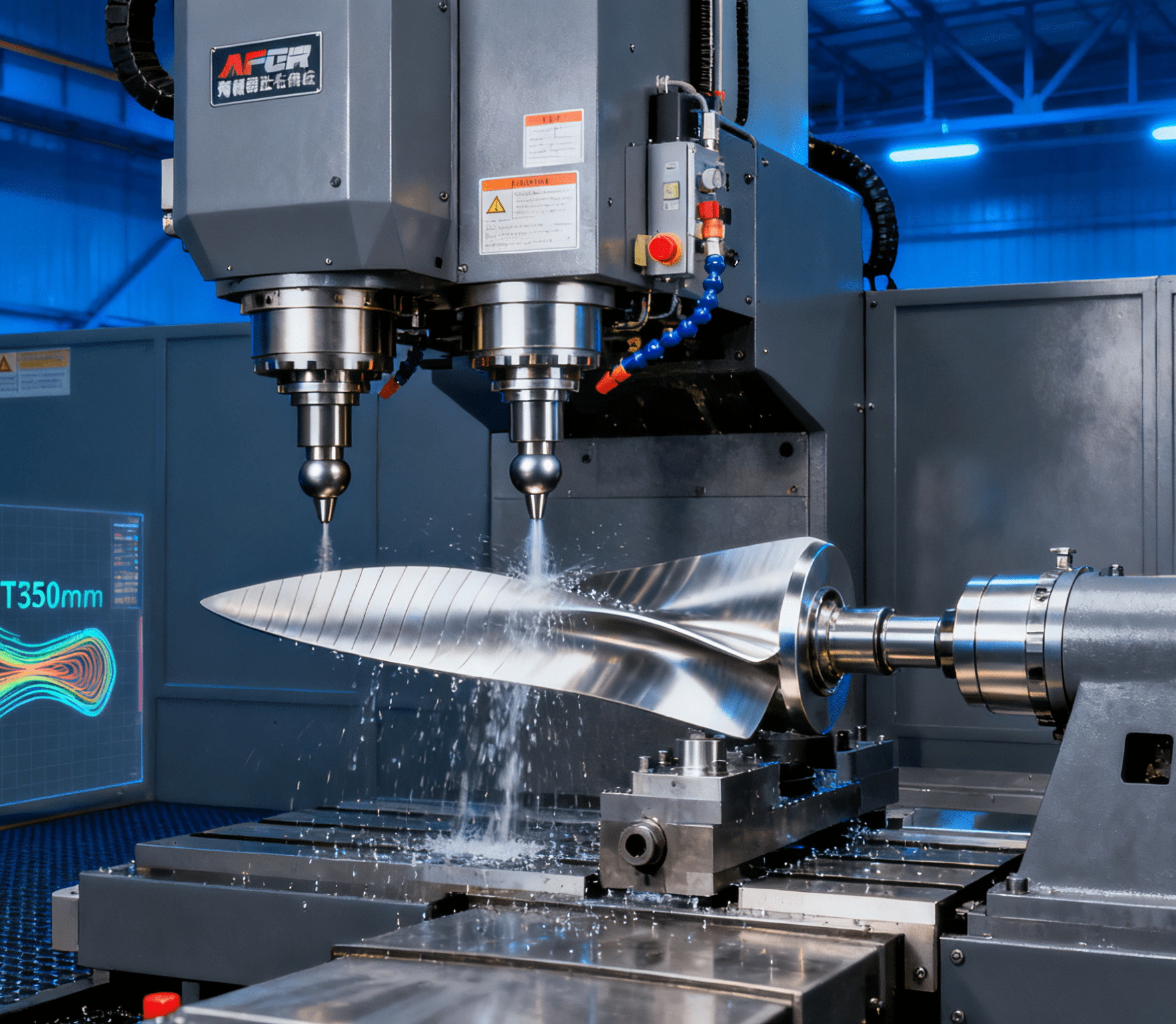

The organic combination of generative AI and intelligent equipment: It has realized the “reverse design” of production processes. By inputting product performance requirements, AI can automatically generate optimal equipment processing paths and parameter configurations, helping enterprises shorten the product R&D cycle.

(2) Production Model Restructuring: From Automation to Autonomy

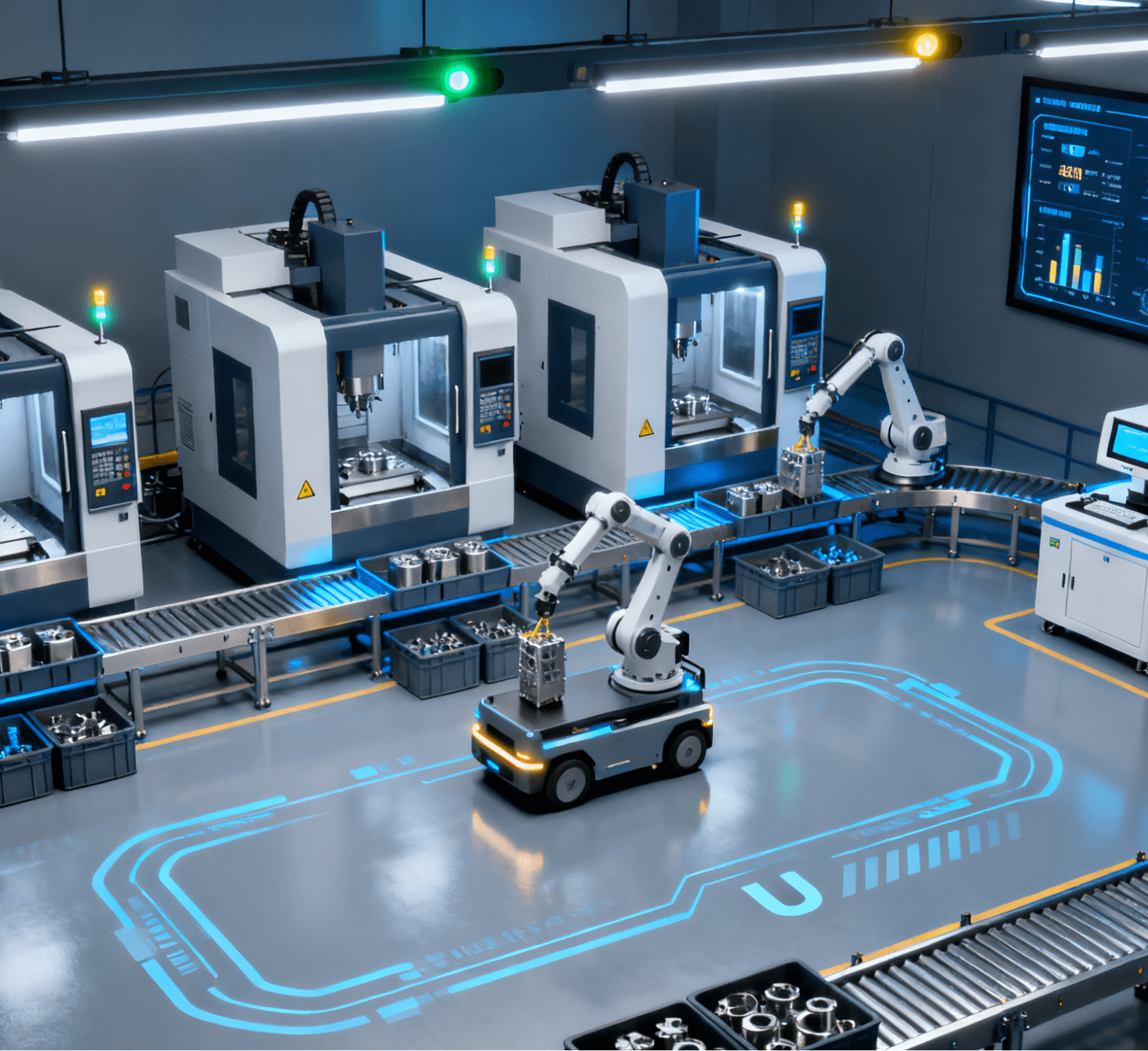

The in-depth penetration and wide application of AI technology have driven the transformation of manufacturing production models from “mechanical automation” to “autonomous intelligent production”, realizing “self-perception, self-decision-making, and self-optimization” in the production process.

In the production scheduling of smart factories: AI systems collect real-time data on equipment operation status, raw material inventory, and order demand on the production line. Through multi-objective optimization algorithms, they dynamically adjust production plans and equipment scheduling. Even if equipment malfunctions, AI can automatically adjust the assignment of production tasks for the equipment and simultaneously generate a fault maintenance plan to avoid production interruptions; when raw material supply is delayed, AI can predict the arrival time of raw materials based on historical data, adjust the production sequence in advance, and give priority to producing products with sufficient inventory to ensure that the order delivery rate is not affected.

In the quality control link: AI systems have transformed the production model from “post-inspection” to “pre-prevention”. By analyzing the correlation between key parameters in the production process and product quality data in real time, they build quality prediction models. When parameters show abnormal trends, early warnings can be issued, and production parameters can be automatically adjusted to prevent the production of non-conforming products.

AI systems have also better realized “flexible customization” of production: Through the connection between AI and customer demand management systems, they can quickly convert customers’ personalized needs into production instructions, realizing “ordering from one piece and mass production”, which fully meets consumers’ personalized customization needs.

(3) Industrial Ecosystem Innovation: Full-Chain Intelligent Upgrading

AI systems have realized the intelligent upgrading of the entire chain including R&D, production, supply chain, sales, and services, promoting the evolution of the manufacturing industry from “single-machine intelligence” to “full-chain collaborative intelligence” and building a new industrial ecosystem.

In the R&D link: The integration of AI and digital twin technology has created a closed-loop system of “virtual R&D – physical verification”. R&D personnel can build virtual models of products on the digital twin platform, use AI to simulate product performance under different working conditions, quickly optimize product design schemes, and reduce the number of physical prototypes, which can significantly shorten the R&D cycle and reduce R&D costs.

In the supply chain link: AI-driven supply chain collaboration platforms have realized real-time information sharing and intelligent linkage among upstream and downstream enterprises. Based on market demand forecasting, they guide upstream suppliers to adjust raw material production plans to avoid inventory backlogs. At the same time, through AI logistics scheduling algorithms, transportation routes and warehouse layouts are optimized to reduce supply chain logistics costs.

In the sales and service links: AI technology can be used to create accurate customer portraits, analyze customers’ consumption habits and demand preferences, and realize precise marketing and personalized recommendations of products; in terms of after-sales service, AI remote diagnosis systems can collect data through equipment sensors to monitor the operation status of equipment in real time, predict equipment failures in advance, and remotely guide customers in maintenance, or dispatch nearby service personnel for on-site service, greatly improving the efficiency of after-sales service.

In the recycling and disposal link: Machine learning can predict community recycling volumes and optimize routes for dynamic scheduling of recycling vehicles; RFID tags can track the flow of large quantities of waste items; computer vision systems can identify waste materials in real time, and spectral analysis technology can identify toxic and harmful substances; image recognition technology can evaluate the wear degree of second-hand goods; blockchain technology can trace and verify high-value parts; and market big data analysis can generate real-time recycling guidance prices.

In-Depth Integration of AI and Manufacturing: A Promising Future for Smart Manufacturing Development

(1) Multi-Technological Integration

The development of smart manufacturing cannot rely solely on the progress of a single AI technology, but on the in-depth integration of multiple frontier technologies, including AI, sensors, the Internet of Things (IoT), big data, cloud computing, and the advancement of manufacturing technology itself.

The development of sensor technology has enabled the observable status of equipment, materials, and factories;

IoT has realized the interconnection of production equipment, products, and raw materials, enabling real-time data collection and transmission, making the entire production system “interconnected”;

Big data provides massive and rich data resources for AI, and through in-depth mining and analysis of this data, AI models can accurately identify potential problems and optimization directions in the production process;

Cloud computing provides strong computing support for data storage and processing, ensuring the efficient completion of large-scale data operations.

Finally, based on this, AI can optimize production processes, predict equipment failures, realize seamless connection and efficient operation of production lines, and comprehensively improve the intelligence and efficiency of the manufacturing industry.

(2) Global Cooperation and Formulation of Norms and Standards

The smart manufacturing industry involves the reshaping and upgrading of the manufacturing industry chain in various countries, requiring extensive global cooperation and the formulation of scientific and reasonable norms and standards.

In terms of technological exchanges: Researchers and enterprises from various countries can share cutting-edge technologies and innovative achievements in the application of AI in manufacturing, accelerating the global popularization and iteration of technologies.

The formulation of norms and standards is even more critical: Unified technical standards and norms (such as communication protocols and data formats) can ensure good compatibility and interoperability between equipment and software systems produced by different countries and manufacturers, reduce integration difficulties caused by standard differences, and comprehensively promote the healthy, orderly, and high-quality development of the smart manufacturing industry.

(3) Towards Dual Carbon Goals and Sustainable Development

With the growing global attention to climate change and the ecological environment, and the continuous enhancement of human environmental awareness, green manufacturing has become a development direction that smart manufacturing must attach great importance to.

At the energy management level: AI can monitor the energy consumption of various equipment in the factory in real time, flexibly adjust the operating power and start-stop time of equipment according to production tasks, and realize the precise allocation and efficient utilization of energy.

AI can incorporate carbon emissions and energy consumption into process design as optimization goals, realizing closed-loop management of “carbon budget” from design and scheduling to recycling;

The edge-cloud collaborative energy-carbon operating system enables factories to become “negative carbon assets” that can be flexibly traded, driving the interconnection of carbon footprint data in the industrial chain, and making “zero-carbon orders” a new pass for exports to Europe and the United States. Ultimately, this will promote the manufacturing industry to enter the carbon peak platform period as a whole by 2030, laying a solid industrial foundation for carbon neutrality by 2060.

Challenges Faced by AI Empowering Smart Manufacturing

(1) Increased Difficulty in Technology Integration

The smart manufacturing system is a large and complex ecosystem, reflecting interdisciplinary integration and integrating a variety of complex technologies (such as mechanical engineering, materials science, automation, computer science, as well as data interfaces, data formats, data communication, system compatibility, and security). In particular, some manufacturers adopt encrypted communication protocols and data formats to protect their own technological advantages, making it difficult for AI systems to obtain correct information and restricting the integrated application of AI technology.

(2) Data Security and Privacy Issues

Data is a core asset, covering key content such as corporate business secrets, production process data, and customer information. Therefore, data security and privacy protection are crucial. With the circulation and sharing of data among different links and subjects, the boundary of data privacy has become blurred. Ensuring that data is not abused and user privacy is not leaked during use requires sound data security mechanisms and privacy protection technology support.

(3) Imperfect Technical Standards and Regulations

Currently, the application and development of smart manufacturing are advancing rapidly, but the formulation of relevant standards and regulations is relatively lagging behind.

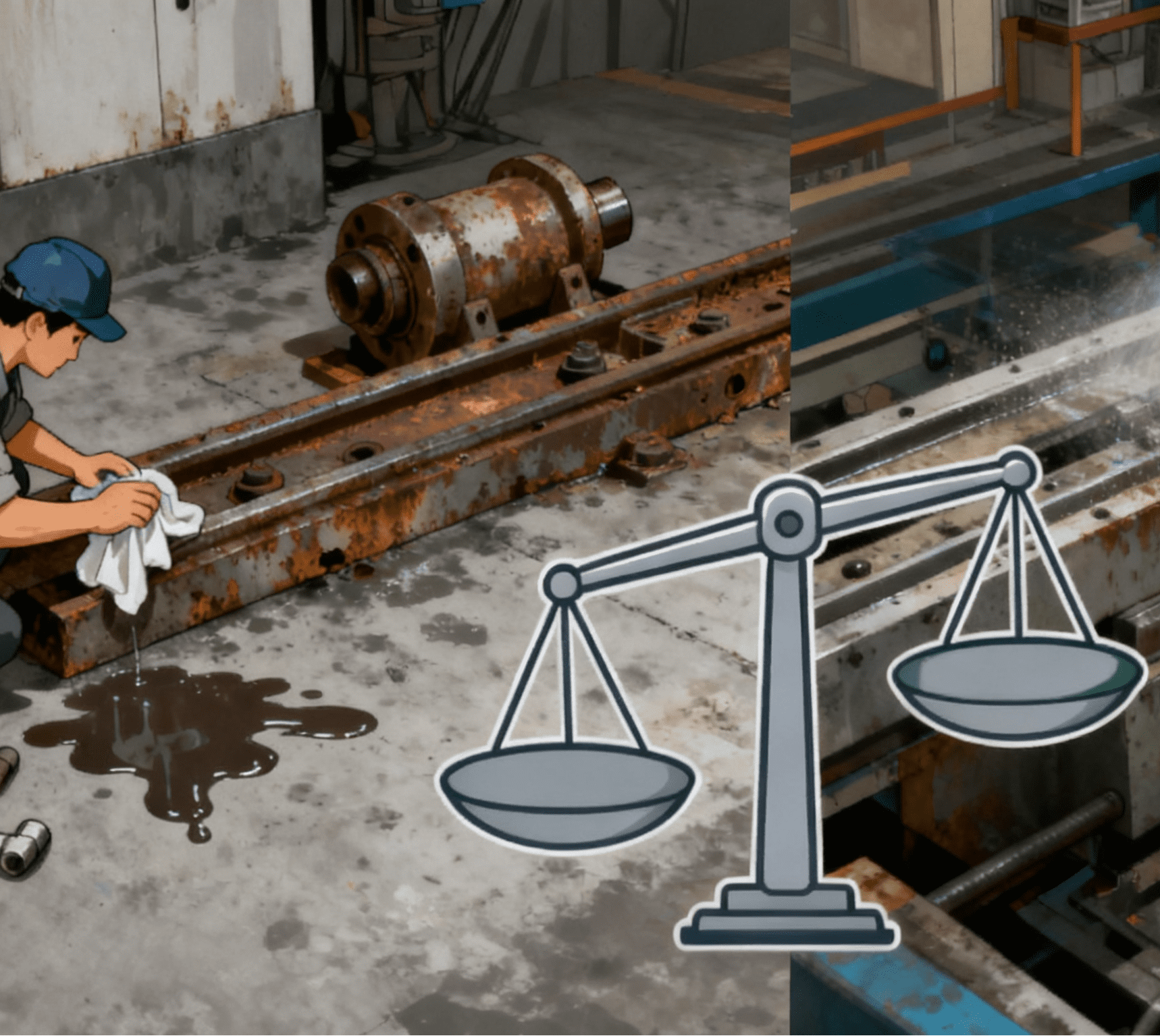

In terms of technical standards: The lack of unified specifications leads to significant differences in functions, performance, and interfaces between AI applications and intelligent equipment developed by different enterprises, affecting the healthy development of the industrial ecosystem.

There are also gaps in regulations: For example, the issue of liability definition caused by AI decisions. When an AI system makes mistakes in production decisions, leading to product quality accidents or production accidents, it is difficult to clearly define whether the algorithm developer, data provider, or the enterprise itself should bear the responsibility. This uncertainty increases enterprises’ concerns about applying AI technology and limits the promotion and application scope of smart manufacturing technologies.

(4) Barriers to Employees’ Acceptance of AI

On the one hand, enterprise employees have doubts about the safety and reliability of AI technology and are worried that the introduction of AI systems will lead to the replacement of their own positions; on the other hand, employees are skeptical about the stability of AI in production and fear that equipment failures will cause production accidents. This sense of distrust in technology reduces employees’ cooperation in the daily application of AI technology, which may affect the popularization and in-depth application of AI technology within enterprises.

Conclusion

AI empowering smart manufacturing is not only an upgrade at the technical level but also a reshaping of the overall ecosystem of the manufacturing industry. AI technology will promote the manufacturing industry to develop rapidly in a more intelligent, efficient, and sustainable direction. To adapt to this development trend:

Enterprises need to formulate long-term strategies for intelligent transformation and digital upgrading, and strengthen cross-field technological integration and talent cultivation;

The government should accelerate the improvement of relevant laws and regulations to provide a sound institutional environment for technological innovation and industrial application;

Industry organizations need to build public platforms for standards and testing certification to promote collaborative innovation among upstream and downstream of the industrial chain;

As the source of knowledge innovation and high-end talent supply, universities should proactively align with industrial needs, establish interdisciplinary disciplines of “AI + Manufacturing”, and continuously cultivate compound talents in the field of AI + smart manufacturing.

Only through the collaborative efforts of all parties can we fully release the potential of AI in smart manufacturing, seize the opportunities brought by the new round of technological revolution, and promote the high-quality and sustainable development of the manufacturing industry.