Introduction: The Revolution of Automated AssemblyThe future of automation is not just evolving—it is undergoing a revolutionary shift that will redefine how we think about human-machine collaboration in one of the most critical areas: assembly. As the founder of Humanoid and a veteran with over a decade in tech entrepreneurship, I’ve witnessed firsthand how advanced technologies transform industries—especially how they’re reshaping automated assembly, a cornerstone of manufacturing that’s long struggled with inefficiency, labor gaps, and rigidity.For context, the U.S. manufacturing sector faces a crisis that makes automated assembly not just a “nice-to-have,” but a necessity. Deloitte and the Manufacturing Institute project that by 2033, the industry will need 3.8 million new workers—and without intervention, 1.9 million of those roles could remain unfilled. This gap isn’t just about numbers; it’s about the complexity of modern assembly tasks: from delicate electronics soldering to heavy automotive component fitting, many jobs are either too repetitive for human sustainability or too precise for consistent manual execution.Yet for all its promise, automated assembly has historically been held back by barriers. Traditional solutions often demand massive infrastructure overhauls, specialized engineering expertise, and prohibitive capital investment. To understand this—and the breakthroughs now changing the game—let’s start with real-world examples of automated assembly today, and how they’re evolving.

Current Examples of Automated Assembly: Strengths and LimitationsAutomated assembly already powers much of modern manufacturing, but its applications vary widely by task complexity and industry. Below are the most common use cases, along with their core strengths and key limitations.

Low Complexity: Material Handling & Basic Component MovementThe simplest form of automated assembly focuses on moving parts to and from workstations—tasks where consistency (not adaptability) is the priority.Example 1: Automated Guided Vehicles (AGVs) in Automotive PlantsIn factories like Ford or Toyota, AGVs navigate pre-programmed routes to transport heavy components (e.g., engine blocks, door panels, EV battery packs) between assembly stations. Unlike manual forklifts, they operate 24/7 without fatigue, reducing delays in the assembly line. For instance, an AGV might ferry a battery pack from the storage area to the EV chassis assembly station, ensuring parts arrive exactly when needed.Example 2: Conveyor-Based Kitting for ElectronicsIn smartphone manufacturing, conveyor systems with automated sorters assemble “kits” of small components (e.g., screws, microchips, connectors) and deliver them to human workers or robotic arms for final assembly. This cuts down on time wasted searching for parts and ensures each kit has the correct components—critical for high-volume production.Limitations: These solutions fail at adaptability. An AGV can’t adjust its path to pick up a misplaced component, and a conveyor can’t reconfigure itself for a new product model without costly retooling.

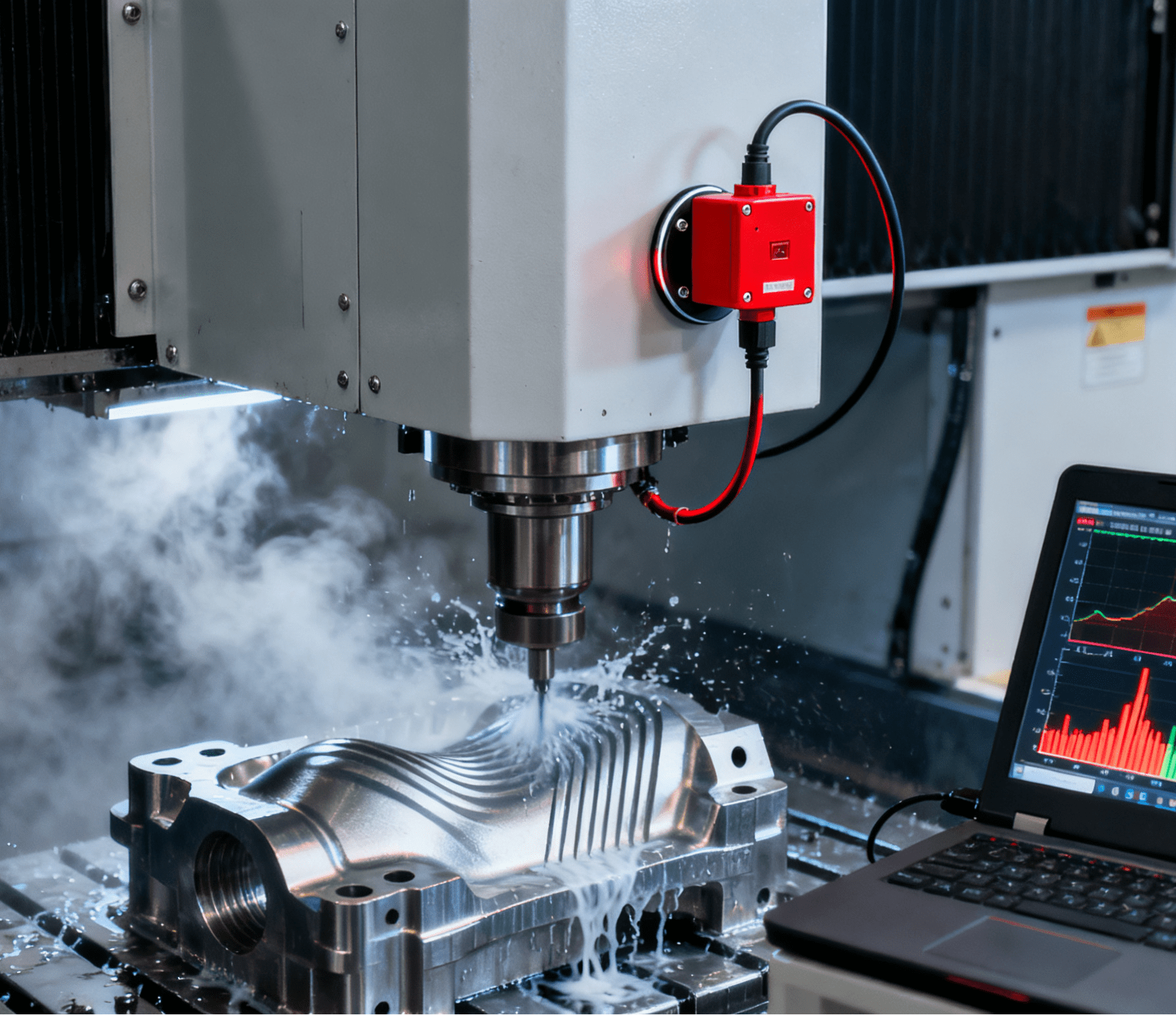

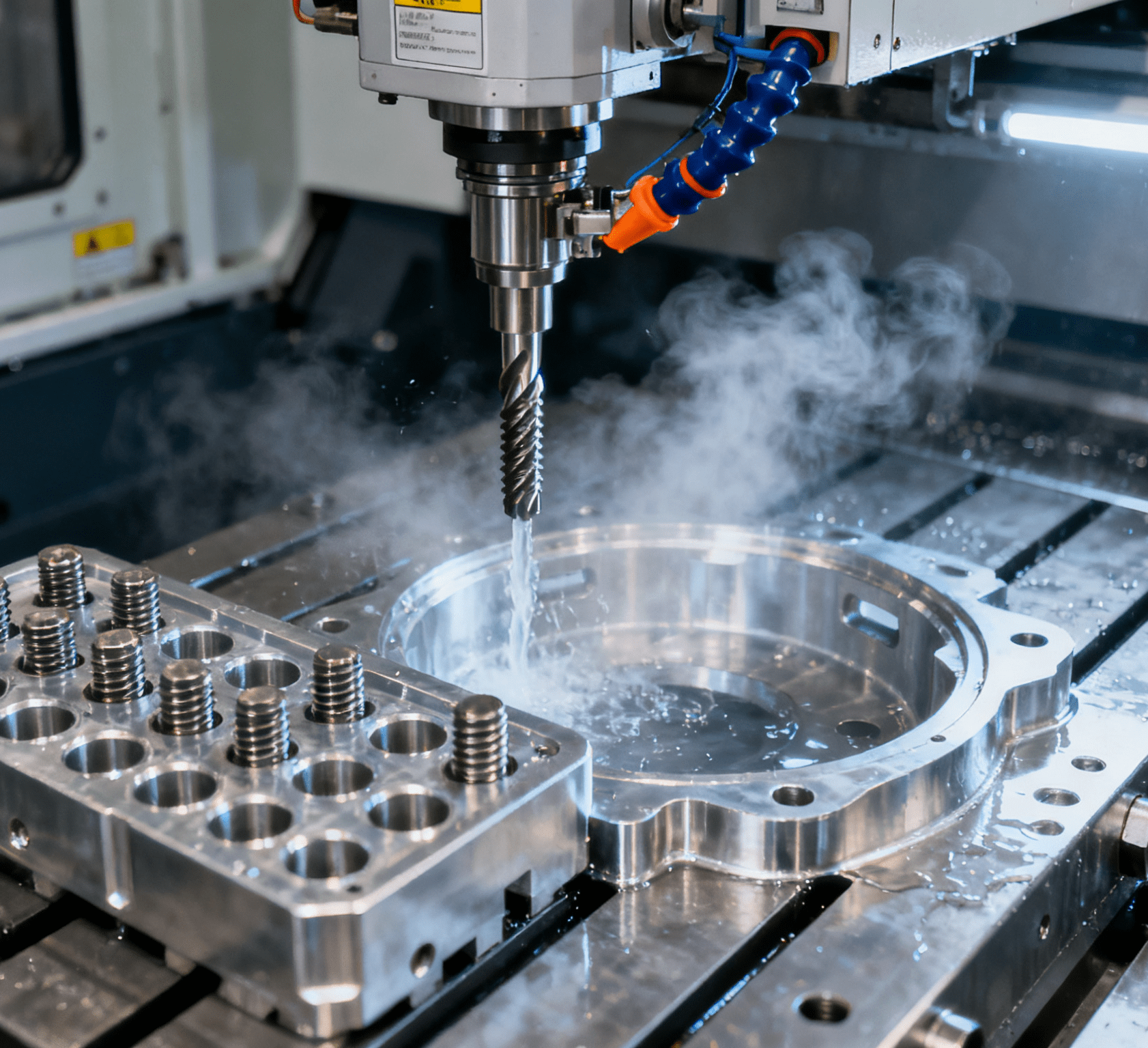

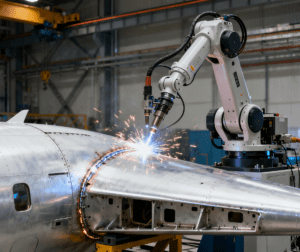

Medium Complexity: Repetitive Precision TasksFor assembly steps that demand consistent accuracy (but little variation), pre-programmed industrial robots are the industry standard.Example 1: Robotic Screw Driving in Appliance ManufacturingCompanies like Whirlpool use robotic arms with torque sensors to fasten screws in washing machine panels. Unlike human workers, these robots apply exactly the right amount of force—avoiding stripped screws or loose fittings—and can complete 500+ cycles per hour (vs. ~150 for a human). This ensures every appliance meets quality standards, reducing warranty claims.Example 2: Welding & Soldering in AerospaceBoeing uses automated welding robots to assemble aircraft fuselage sections. These robots handle high-heat, repetitive welds on aluminum or titanium parts with a precision of 0.1mm—far beyond human capability. Similarly, in electronics, automated soldering machines attach microchips to PCBs (printed circuit boards) at speeds of 1,000+ joints per minute, critical for devices like laptops or wearables.Limitations: These robots are highly inflexible. A welding robot programmed for a 737 fuselage can’t switch to assembling a smaller drone part without days of reprogramming and new fixtures. They also often require dedicated floor space and safety barriers—making them impractical for small to mid-sized manufacturers.

Bridging Flexibility Gaps: Univerzální montážní systém address this rigidity, many manufacturers now adopt Universal Assembly Systems—modular automation platforms designed for medium-variety production. Equipped with interchangeable toolheads (e.g., vacuum grippers for delicate parts, torque-controlled drivers for fasteners) and adaptive software, these systems avoid the “one-task-only” limitation of traditional robots. For example, a mid-sized automotive parts maker might use a Universal Assembly System to alternate between assembling HVAC sensors and dashboard buttons: with preset software templates and quick-swap tooling, it reconfigures in 30 minutes—no full reprogramming or new fixtures needed. This makes it ideal for brands producing multiple product lines (e.g., a kitchen appliance company making both blenders and air fryers) while keeping costs lower than fully custom automation. While they improve flexibility for medium-complexity tasks, they still lack the dexterity to handle high-variability work like fitting irregularly shaped pharmaceutical components.

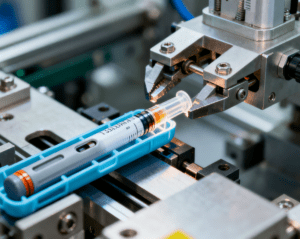

High Complexity Gap: Flexible, Dexterity-Driven AssemblyThe biggest challenge in automated assembly lies in tasks that mimic human dexterity: sorting irregularly shaped parts, fitting delicate components, or adapting to slight variations in incoming materials. Until recently, these jobs were impossible to automate without expensive overhauls.Example 1: Pharmaceutical Insulin Pen AssemblyA pharmaceutical plant assembling insulin pens needs to handle tiny, fragile cartridges and align them with plastic casings—tasks where even a 1mm error ruins the product. Traditional robots can’t adjust for minor variations in cartridge size.Example 2: Modular Furniture AssemblyA furniture manufacturer assembling modular sofas needs to attach legs, cushions, and fabric covers—each with slightly different dimensions. Pre-programmed robots can’t “feel” if a leg is misaligned and adjust accordingly.This gap is where the next wave of automated assembly—led by humanoid robots—is making its mark.

The Next Era of Automated Assembly: Humanoid Robots as a Solution

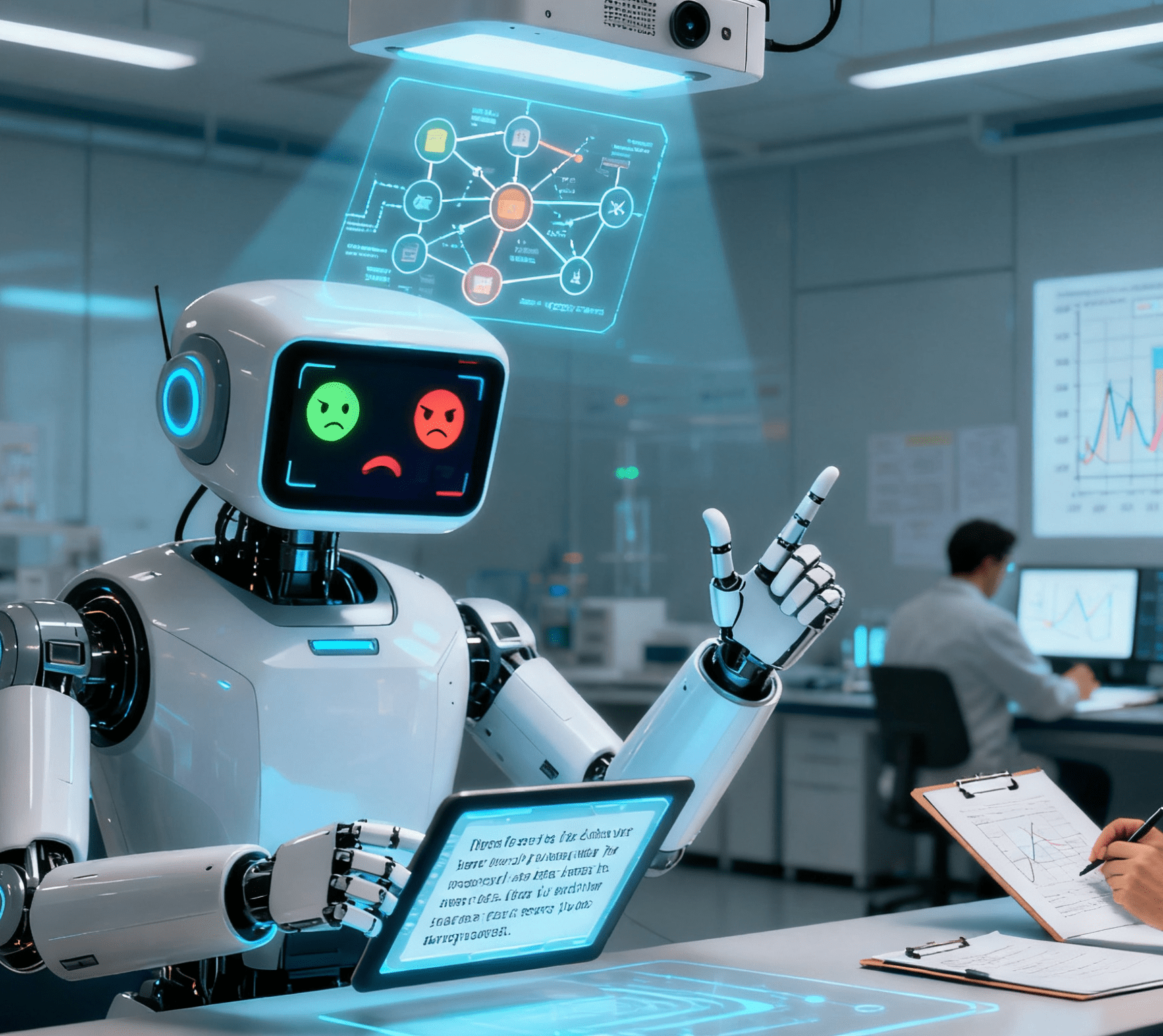

The future of automated assembly isn’t about replacing humans—it’s about creating tools that collaborate with them, matching human flexibility while integrating seamlessly with existing infrastructure. At Humanoid, we’re building robots designed for complex assembly tasks that overcome the limitations of traditional automation. Below are upcoming real-world applications:

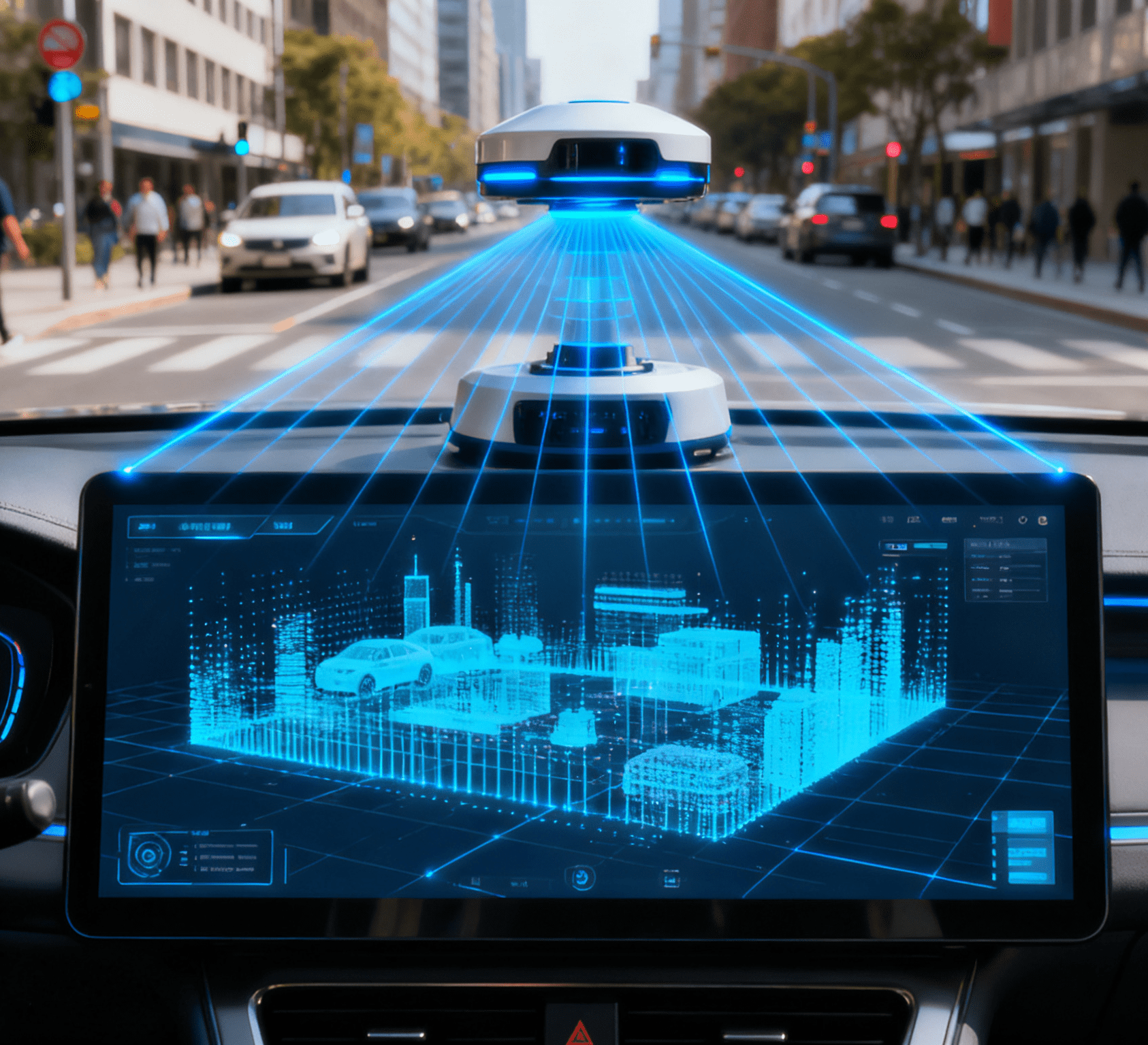

Example 1: Electronics Assembly for Custom DevicesImagine a startup building custom IoT sensors—each with unique component layouts. A humanoid robot could:Pick up irregularly shaped sensors from a bin (using computer vision to “see” and adapt to placement variations),Align the sensor with a PCB (adjusting for slight size differences in incoming parts),Solder the connection with precision, andInspect the finished assembly—all without retooling.This eliminates the need for custom fixtures (which cost $10,000+ per product model) and lets small manufacturers automate low-volume, high-variety assembly—something previously impossible.

Example 2: Automotive Interior AssemblyIn EV factories, humanoid robots could assemble dashboards, which require fitting multiple components (screens, air vents, wiring harnesses) into curved, irregularly shaped frames. Unlike traditional robots, they can:“Reach” into tight spaces (mimicking human arm movement),Adjust for minor variations in dashboard frame size (common in mass production),Handle delicate wiring without damaging it, andWork alongside human workers (no safety barriers needed, thanks to built-in collision detection).This cuts down on assembly time (from 30 minutes per dashboard to 15) and reduces errors, while using the same factory floors and workstations—no infrastructure overhauls required.

Why This Matters: The Impact of Accessible Automated Assembly

When automated assembly becomes flexible, affordable, and easy to use, it solves the manufacturing labor gap and unlocks new possibilities for businesses of all sizes:

Humans Focus on High-Value WorkBy automating monotonous, error-prone assembly tasks (e.g., screw driving, part fitting), workers can shift to higher-value activities: designing new products, optimizing workflows, or troubleshooting complex issues. For example, a worker in a medical device plant who once spent 8 hours a day assembling syringes can now train the humanoid robot, monitor quality, and collaborate with engineers on product improvements. This boosts productivity and employee satisfaction—key to retaining talent in a tight labor market.

Faster Operations, More GrowthAutomated assembly speeds up production without sacrificing quality. A humanoid robot working on appliance assembly can operate 24/7, increasing throughput by 50% or more. For a mid-sized manufacturer, this means meeting sudden spikes in demand (e.g., a surge in orders for space heaters during a cold winter) without hiring temporary workers. It also lets businesses scale into new markets—e.g., a furniture maker now able to assemble 2x more sofas can expand to sell in Europe or Asia.

Consistency That Builds TrustIn industries like pharmaceuticals or aerospace, quality is non-negotiable. Humanoid robots for automated assembly reduce errors to near-zero: for example, a robot assembling medical devices can inspect each step in real time (using sensors to “feel” if a component is properly fitted), cutting defect rates from 5% (human-led) to 0.1%. This not only saves money on wasted materials but also strengthens brand reputation—critical for regulated industries.

Conclusion: Automated Assembly as a Catalyst for Manufacturing’s Future

Automated assembly has come a long way from AGVs and pre-programmed robots—but its true potential lies in tools that match human adaptability. For too long, small to mid-sized manufacturers were locked out of automation due to cost and rigidity; humanoid robots are changing that, making automated assembly accessible, flexible, and collaborative.

At Humanoid, we’re not just building robots—we’re redefining what’s possible for manufacturing. By focusing on user-friendly design (no specialized engineering needed), low total cost of ownership (TCO), and modularity (swap out hands for different tasks), we’re empowering businesses to automate even the most complex assembly jobs.

The result? A manufacturing sector where labor gaps are filled, productivity soars, and innovation thrives. Automated assembly isn’t just a technology—it’s a catalyst for a more resilient, efficient, and human-centered industry. And the best part? It’s already here.