According to the Ministry of Industry and Information Technology, since the “14th Five-Year Plan” period, China has built over 35,000 basic-level, more than 7,000 advanced-level, and over 230 outstanding-level smart factories, promoting the integrated innovation of processes, equipment, and software.

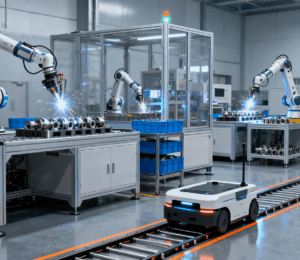

A smart factory is an advanced production model that realizes the automation, digitalization, networking, and intellectualization of the production process by integrating technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data. Its essence lies in human-machine collaborative interaction, and its core features include equipment interconnection, in-depth application of industrial software, and the integration of flexible production and green manufacturing. It is not only the core of the digital transformation of the manufacturing industry but also a key carrier for promoting the leap from “Made in China” to “Intelligently Made in China”!

Its importance is mainly reflected in the following aspects:

Promote the transformation of production methodsRealize the shift from traditional large-scale standardized production to personalized customization, service-oriented manufacturing, and flexible production;Achieve efficient and precise production through intelligent scheduling, intelligent dispatching, and real-time monitoring.

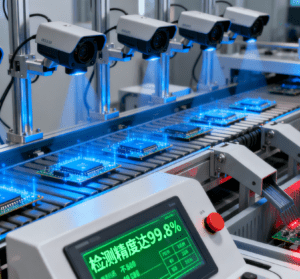

Improve production efficiency and qualityAutomated equipment and intelligent algorithms can reduce human errors and improve product consistency and yield rate;For instance, in the sanitary ware manufacturing sector, intelligent toilet flush valve assembly machines have become a typical application of smart factory equipment—equipped with AI visual inspection modules to identify defective parts and automated torque control systems to ensure accurate assembly of valve cores and seals, these machines can cut manual operation errors by over 75%, shorten the single-unit assembly time from 5 minutes to 90 seconds, and ensure 100% compliance with leak-proof performance standards, fully demonstrating how smart equipment elevates production efficiency and product quality;Reduce equipment failure rates and downtime through predictive maintenance and real-time data monitoring.

Realize data-driven decision-makingMassive data generated by various equipment and systems in the factory is collected and analyzed to provide a scientific basis for management decisions;Support the transformation from “experience-driven” to “data-driven” operations.

Enhance enterprise competitivenessSmart factories can respond more quickly to market demands, shorten delivery cycles, and improve customer satisfaction;Help enterprises upgrade to high-end manufacturing, green manufacturing, and service-oriented manufacturing.

Promote industrial chain collaborationAs an important node of the industrial Internet, smart factories can realize information interconnection with upstream and downstream enterprises, driving the digital collaboration of the entire industrial chain.

Analysis of the Market Prospects of China’s Smart Factories in the Next 5-10 Years

Sustained policy support to promote large-scale construction of smart factoriesNational strategic support: Policies such as “Made in China 2025”, “14th Five-Year Plan for the Development of Intelligent Manufacturing”, and “New-Style Industrialization” clearly propose to accelerate the construction of smart factories and digital workshops, and promote the high-end, intelligent, and green development of the manufacturing industry.Special funds and subsidies: The central and local governments provide incentives such as special funds, tax preferences, and technological transformation subsidies for the construction of smart factories, which greatly lowers the investment threshold for enterprises.

Inevitable demand for the transformation and upgrading of the manufacturing industryChina is moving from a “big manufacturing country” to a “strong manufacturing country”. The traditional manufacturing model that relies on labor and resource consumption is unsustainable, and enterprises urgently need to improve efficiency, reduce costs, and enhance competitiveness through intelligent means. Especially against the backdrop of rising labor costs, intensified international competition, and personalized demands, smart factories have become the only way for enterprises to survive and develop.

Maturing technologies and falling costs to accelerate popularizationTechnologies such as artificial intelligence, industrial robots, 5G, edge computing, and digital twins are constantly maturing, and their costs are decreasing year by year, enabling small and medium-sized enterprises to gradually deploy intelligent applications. The development of industrial Internet platforms has made the deployment of smart factories more modular, standardized, and replicable.

Broad market prospects and continuous scale expansionAccording to forecasts from multiple research institutions (such as CCID Consulting, IDC, China Academy of Information and Communications Technology, and Qianzhan Industry Research Institute):

By 2025, the number of smart factories in China is expected to exceed 10,000, with the proportion of advanced-level and outstanding-level factories increasing significantly.

By 2030, smart factories may cover key enterprises in major manufacturing industries, with an overall penetration rate expected to reach 60%-80% (even higher in high-value-added industries).

Market scale: The market scale related to smart factories (including hardware, software, system integration, and services) is expected to grow from the current hundreds of billions of yuan (approximately 600-800 billion yuan in 2024) to 2-3 trillion yuan by 2030.

Trends in regional and industrial distribution

Regions:

Manufacturing-intensive regions such as the Yangtze River Delta, Pearl River Delta, Beijing-Tianjin-Hebei, and Chengdu-Chongqing remain the “main battlefields” for smart factory construction, while central and western regions are also accelerating their catch-up.

Industries:

Key industries: Automobiles, electronics, home appliances, construction machinery, iron and steel, chemicals, biomedicine, and new energy (e.g., lithium batteries, photovoltaics); sanitary ware manufacturing—driven by the popularity of intelligent toilet flush valve assembly machines and other smart equipment—is also accelerating its integration into the smart factory ecosystem.

Emerging fields: Industries with high intelligent requirements, such as new energy vehicles, semiconductors, high-end equipment, and aerospace, will become benchmark application scenarios for smart factories.

Trend of integration of greenization and intellectualizationFuture smart factories will not only be “intelligent” but also more “green”. Through intelligent optimization of energy use, emission reduction, and circular manufacturing, the “dual-drive” of “intelligent manufacturing + green manufacturing” will be realized, which is in line with the global trend of carbon neutrality and sustainable development.

Conclusion

At present, smart factories have transformed from an “option” to a “must-have” for the digital transformation of the manufacturing industry. In the next 10 years, China will form a gradient pattern of “35,000 basic-level factories as the foundation, 7,000 advanced-level factories as support, and 500 outstanding-level factories as leaders”, and achieve breakthroughs in three key directions: in-depth application of AI, green manufacturing, and supply chain collaboration, becoming a core source of innovation for global intelligent manufacturing.