Table of Contents

ToggleRevolutionizing Bathroom Component Assembly: How Intelligent Assembly Machines Reshape Industrial Production Paradigms

In the wave of global bathroom industry’s transformation towards intelligence, bathroom component assembly machines are upgrading from traditional mechanical automation to “AI + flexible manufacturing”. Recently, Ruizhi Intelligence launched a new generation of Bathroom Components Assembly Machine, which provides systematic solutions for the assembly challenges of complex bathroom products such as faucets and shower systems with micron-level precision and adaptive production capabilities, driving the industry’s leap from mass production to customized manufacturing.

Core Technological Breakthroughs: Three-Dimensional Evolution from Mechanical Execution to Intelligent Decision-Making

Dynamic Visual Positioning System: Revolutionary Upgrade of Industrial Vision

The new-generation assembly machine is equipped with a 12K ultra-high-definition industrial vision module, adopting dual-spectrum imaging technology (visible light + infrared light), which can penetrate the chrome-plated surfaces and transparent seals of bathroom components to accurately identify hidden defects. Its core technical highlights include:

- Nanometer-level Calibration Algorithm: Calibrating the vision system through a laser interferometer, the pixel accuracy is improved to 0.002mm/px, equivalent to identifying defects as thin as 1/50 of a hair in a 20cm field of view. In the assembly of faucet cartridges, the system can real-time detect 0.005mm-level scratches on ceramic plates, increasing the detection accuracy by 10 times compared with traditional vision solutions.

- Deep Learning Defect Library: An AI model built-in with 860,000 defect samples of bathroom components can automatically identify 237 typical defects such as pinholes, flow marks, and thread damages. After application by an Italian bathroom manufacturer, the manpower in the quality inspection process was reduced from 15 to 3, and the defect missed detection rate dropped from 0.8% to 0.02%.

- Dynamic Compensation Technology: For high-speed assembly scenarios (such as production lines with 120 components per minute), the system calculates the movement trajectory of components 0.1 seconds in advance through predictive algorithms, and adjusts the pose of the robotic arm in real-time with servo motors, solving the delay problem of traditional vision’s “photograph-processing-action” and achieving dynamic positioning error ≤0.03mm during movement.

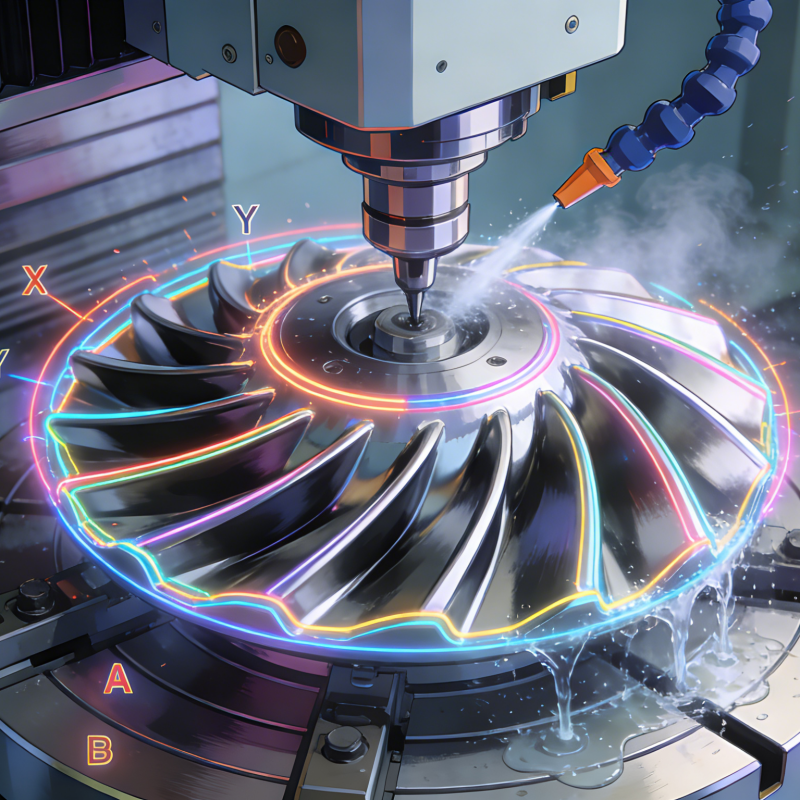

Flexible Force-Controlled Robotic Arm: Integration of Bionics and Intelligent Control

The seven-axis force-controlled robotic arm, using aviation-grade titanium alloy skeleton and memory alloy drive joints, constructs a closed-loop system of “perception-decision-execution”:

- Six-Dimensional Force Sensor Matrix: 32 micro pressure sensors are integrated at the end of the robotic arm, which can real-time sense the force in X/Y/Z axes and the moments of pitch/yaw/roll with an accuracy of 0.01N·m. When installing ceramic cartridges, the system automatically judges the compression amount of the seal according to the pressure curve, and immediately triggers an emergency stop within 0.1 seconds when abnormal resistance (such as impurity jamming) is detected, avoiding glaze cracking caused by traditional rigid assembly.

- Adaptive Impedance Control: For components of different materials (brass, PVC, ceramic), the robotic arm can automatically switch among three force control modes:

| Mode | Application Scenario | Force Control Accuracy | Application Case |

| Rigid Mode | Metal bolt tightening | ±0.05N·m | Faucet body fixing |

| Compliant Mode | Silicone seal pressing | ±0.02N | Shower pipe interface sealing |

| Collision Protection Mode | Fragile ceramic component assembly | 0.5N trigger | Ceramic cartridge installation for smart toilets |

- Force Control Process Library: 89 sets of force control parameters for bathroom components assembly are pre-stored. For example, the hose connection of a hand-held shower needs to maintain an axial tension of 2.3±0.2N, and the system can automatically retrieve the corresponding process, allowing new employees to get started quickly without training.

Modular Changeover System: 15-Minute Production Paradigm Switching

The equipment adopts a plug-in modular design, achieving flexible production in three dimensions through industrial-grade quick-change interfaces:

Rapid Tooling Module Switching: Dedicated tooling modules are developed for three categories of products: faucets, shower columns, and smart toilets:

- Faucet module: Integrated with multi-axis tightening mechanism and angle detection device, capable of simultaneously completing cold and hot water pipe docking and handle angle calibration;

- Shower column module: Equipped with 3D pipe welding robot and automatic sealant coating head;

- Smart toilet module: Built-in circuit detection tooling and ceramic buffer fixtures.

Through the hydraulic quick-locking device, the module replacement time is compressed to 8 minutes, increasing efficiency by 90% compared with traditional screw fixing methods.

Automatic Software Parameter Configuration: During changeover, the MES system automatically pushes the BOM table and process documents of the corresponding product, and the equipment control system optimizes the assembly path through AI algorithms. For example, when switching from hand-held shower production to thermostatic faucet production, the system re-plans the robotic arm movement trajectory according to the 3D model of components, avoiding the 2-hour parameter debugging required by traditional manual programming.

Multi-Line Collaborative Production: The modular design supports the equipment to be expanded into a flexible production line, connecting each assembly unit through AGV logistics carts. After a leading domestic bathroom enterprise deployed a production line composed of 3 such equipment, it can simultaneously produce 20 different models of faucets, reducing the changeover cost by 75%, and shortening the production cycle of small-batch orders (≤500 pieces) from 72 hours to 24 hours.

Application Scenarios in Practice: Dual Improvement of Efficiency and Quality

Precision Component Assembly of Faucets

In the production line of thermostatic faucets of a German bathroom brand, the assembly machine has demonstrated disruptive advantages:

- Traditional manual assembly: 8 workers were required to complete the installation of 12 components such as cartridges, temperature sensors, and handles, taking 12 minutes per unit, and causing a 15% water leakage risk due to uneven manual force.

- Intelligent equipment assembly: The robotic arm automatically tightens bolts according to the preset torque (±0.05N·m), and the vision system simultaneously detects the compression amount of the seal. The assembly time per unit is shortened to 4 minutes, and the water leakage rate is reduced to below 0.3%. The labor cost of the production line is reduced by 62.5%, saving over 2 million euros in quality loss costs annually.

Integrated Assembly of Shower Systems

For the complex process of multi-pipe docking of shower columns, the equipment adopts 3D path planning technology:

- First, a 3D model of the internal pipes of the shower column is generated through laser scanning, and then the optimal assembly sequence is calculated by an AI algorithm. The robotic arm, equipped with multi-grip tools, simultaneously completes pipe welding and sealant application, increasing efficiency by 2.8 times compared with traditional segmented assembly. After application by an American bathroom manufacturer, the qualified rate of water leakage detection for shower systems increased from 89% to 99.7%, and the daily production capacity increased from 500 sets to 1,400 sets.

Industry Impact: Opening the Era of Bathroom Manufacturing 4.0

With the surge in demand for customized bathroom products among Generation Z consumers (it is expected that personalized orders will account for 35% by 2025), the flexibility of assembly machines has become the core competitiveness of enterprises. The R&D director of Ruizhi Intelligence pointed out that the equipment supports real-time docking with the MES system through API interfaces, allowing customers to customize faucet colors and functional modules online, and the system automatically generates assembly parameters, truly achieving the agile response of “production upon order placement”.

At present, the equipment has been implemented in the smart factories of global Top 10 bathroom brands such as TOTO and Kohler, averagely reducing the workshop floor area by 30% and the energy consumption by 18% compared with traditional equipment. Industry analysts predict that the market size of bathroom component assembly machines will grow at an average annual rate of 27% in the next 3 years, and equipment with AI vision and modular design will become the mainstream, promoting the thorough transformation of the bathroom industry from “manufacturing” to “intelligent manufacturing”.

#BathroomSmartManufacturing #AssemblyAutomation #Industry4.0 #FlexibleManufacturing