Lip gloss products are highly favored by consumers for their delicate texture and diverse colors, but the assembly process of lip gloss bottles has long been troubled by defects such as leakage, loose capping, and scratch marks. These defects not only lead to material waste and increased costs but also damage brand reputation. For cosmetics enterprises, solving lip gloss bottle assembly defects is crucial to improving production efficiency and market competitiveness. Ruizhi Intelligent Manufacturing, focusing on non-standard automation, provides targeted solutions to help enterprises eliminate assembly defects.

Common Lip Gloss Bottle Assembly Defects and Their Causes

The main defects in lip gloss bottle assembly include three types. First, leakage caused by improper fitting of the bottle body and cap, which is mostly due to inaccurate positioning during manual assembly. Second, scratches on the bottle surface, resulting from manual handling and assembly operations that are difficult to control the strength uniformly. Third, loose capping or excessive tightness, which is caused by the inconsistency of manual capping force. In essence, these defects are closely related to the low precision, poor consistency and high subjectivity of manual operations, and it is difficult to fundamentally solve them by relying on manual improvement.

Core Solutions: Non-Standard Automated Assembly Equipment

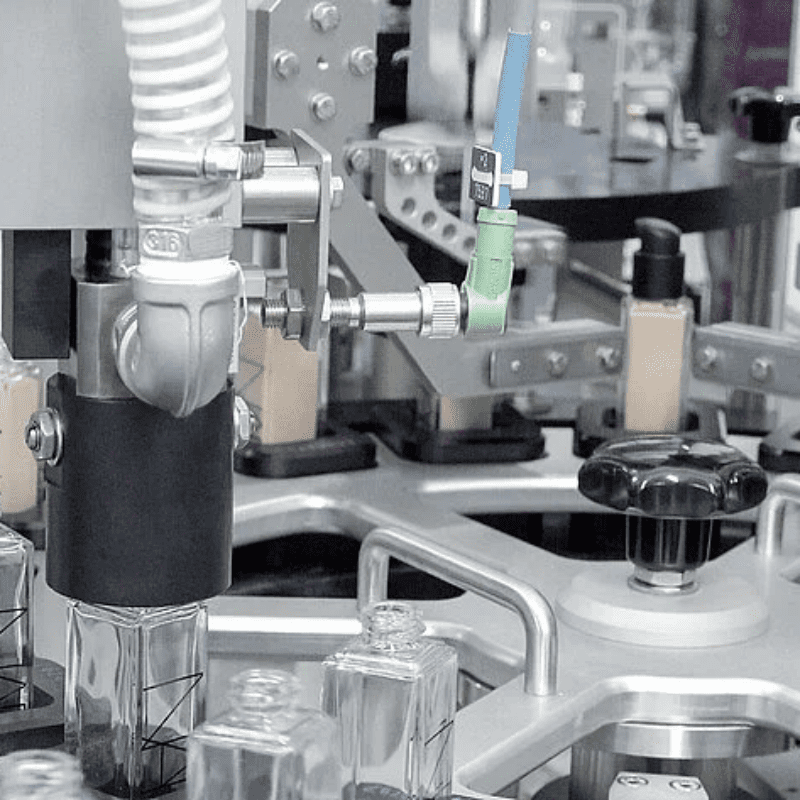

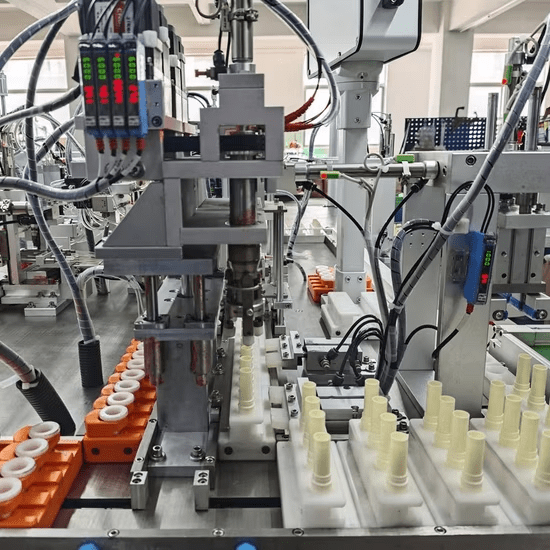

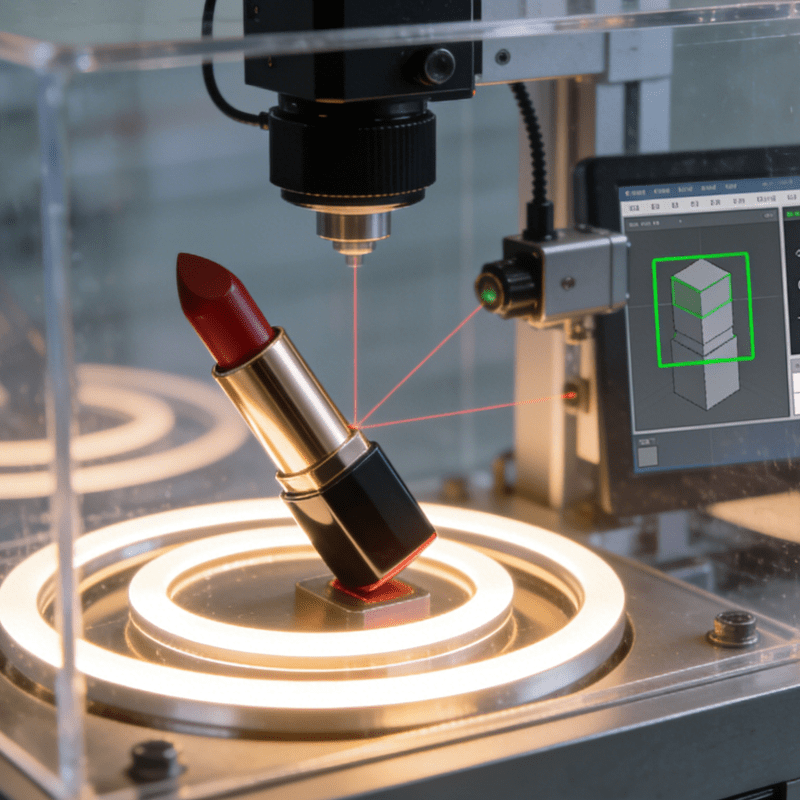

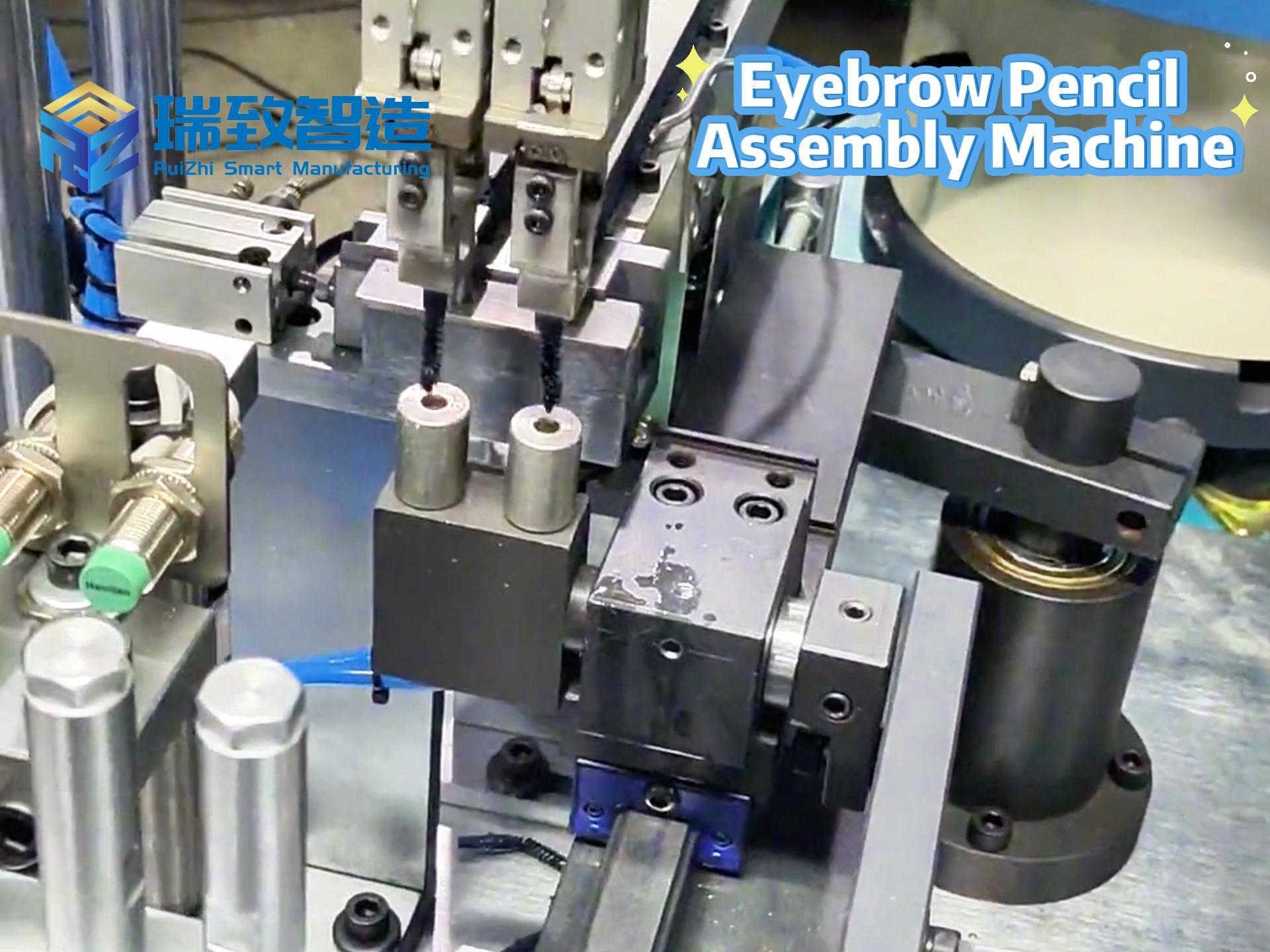

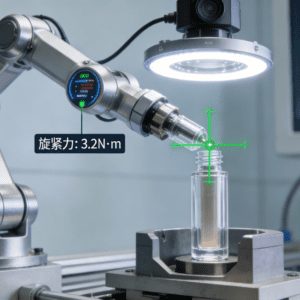

The fundamental way to solve assembly defects is to replace manual operations with non-standard automated assembly equipment. Compared with traditional standard equipment, non-standard automation can be customized according to the specific specifications, shapes and process requirements of lip gloss bottles. Equipped with advanced servo control and machine vision systems, the automated assembly machine can achieve pixel-level precise positioning, ensuring the perfect fitting of the bottle body and cap and avoiding leakage. At the same time, the equipment adopts standardized mechanical operations to control the force and speed uniformly, eliminating scratches and ensuring consistent capping tightness.

Customized Defect-Free Assembly Solutions

Ruizhi Intelligent Manufacturing has rich experience in the field of cosmetic packaging automation. Our customized lip gloss bottle assembly machines integrate multiple processes such as automatic feeding, precise positioning, capping and detection, realizing one-stop defect-free assembly. The equipment supports quick switching between different specifications and shapes of lip gloss bottles, adapting to the flexible production needs of enterprises. In addition, we are equipped with an intelligent detection system that can instantly identify unqualified products and reduce the defect rate to below 0.2%. From pre-sales demand communication to in-sales equipment commissioning and after-sales maintenance, we provide full-cycle services to ensure the stable operation of the equipment.

Solving lip gloss bottle assembly defects is the key to improving production quality and efficiency. Choosing Ruizhi Intelligent Manufacturing’s non-standard automated assembly solution means choosing a stable, efficient and defect-free production mode. Let us help you get rid of the trouble of assembly defects and enhance the core competitiveness of your products in the market.