In the field of mold machining, precision determines the quality and service life of molds, which in turn affects the production of subsequent products. As an advanced machining technology, Electrical Discharge Machining (EDM) plays a crucial role in CNC precision machining, and it exhibits unique advantages especially in precision mold manufacturing.

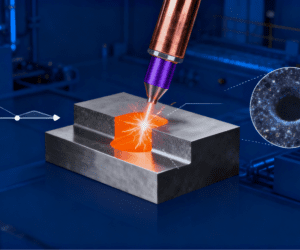

EDM is based on the principle of electrical discharge erosion. By applying a pulsed voltage between the tool electrode and the workpiece, an instantaneous discharge channel is formed in a specific dielectric medium. At the moment of discharge, extremely high temperatures are generated within the channel, causing the metal on the workpiece surface to melt rapidly and even vaporize, thereby achieving material removal. This machining method is completely different from traditional mechanical cutting. It does not rely on mechanical force, so it can process materials of various hardness levels, including high-hardness mold steel and cemented carbide—something that traditional machining methods find difficult to achieve.

Advantages of EDM in Precision Mold Manufacturing

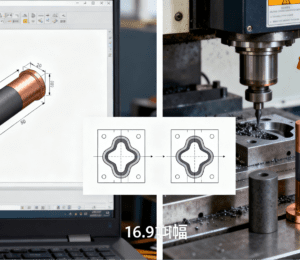

Processing complex shapes: Precision molds often have complex shapes and tiny structures, which are hard to achieve with traditional machining methods. EDM, however, can produce electrodes with corresponding shapes according to the mold’s design requirements. Through electrical discharge between the electrode and the workpiece, it can accurately machine various complex structures such as mold cavities and cores. For example, when manufacturing molds for mobile phone casings, the subtle textures and complex contours inside the mold can all be accurately reproduced via EDM; for the core molds of catheter assembly machines—used in medical device production—EDM can precisely machine tiny fluid channels, ultra-fine fitting structures, and smooth inner cavities that meet sterile requirements, ensuring the catheter’s assembly accuracy and biocompatibility.

High precision: Supported by CNC precision machining, EDM can achieve extremely high machining precision. By precisely controlling discharge parameters (such as pulse width, pulse interval, and discharge current), machining errors can be controlled within an extremely small range, meeting the strict dimensional accuracy requirements of precision molds. For some high-precision molds, the dimensional tolerance can be controlled within ±0.001mm.

Excellent surface quality: The surface roughness of molds processed by EDM is low, reaching Ra0.1 – Ra0.8μm. This is of great importance for molds that require high surface quality, such as optical lens molds, injection molds, and molds for catheter assembly machines. A low-roughness surface avoids damaging the delicate catheter material during assembly and reduces the risk of bacterial adhesion, while also minimizing subsequent polishing processes to improve production efficiency.

Key Steps for Achieving Precision Mold Manufacturing with EDM

Electrode design and manufacturing: Design and manufacture appropriate electrodes based on the mold’s shape and size. Electrode materials are usually red copper or graphite, which have good electrical conductivity and machinability. The precision and surface quality of the electrode directly affect the machining precision of the mold. Therefore, high-precision machining equipment and processes should be used when manufacturing electrodes.

Machining parameter setting: Reasonably set EDM parameters according to the mold’s material, shape, and precision requirements. This requires rich experience and an in-depth understanding of machining principles. Different parameter combinations will result in different machining effects, such as machining speed, surface roughness, and dimensional accuracy.

Machining process monitoring: During the machining process, real-time monitoring of the machining status is necessary, including parameters such as discharge gap, machining current, and voltage. If abnormalities are detected (e.g., unstable discharge, excessive electrode wear), machining parameters should be adjusted in a timely manner or corresponding measures should be taken to ensure the smooth progress of machining.

In CNC precision machining, EDM provides an efficient and high-precision solution for precision mold manufacturing—including the specialized molds required for catheter assembly machines. By deeply understanding its principles, giving full play to its advantages, and strictly controlling the key steps of machining, it is possible to manufacture precision molds that meet various needs (from consumer electronics to medical devices) and promote the development of the mold machining industry. If you want to learn more about EDM application cases or technical details, please feel free to ask me.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine