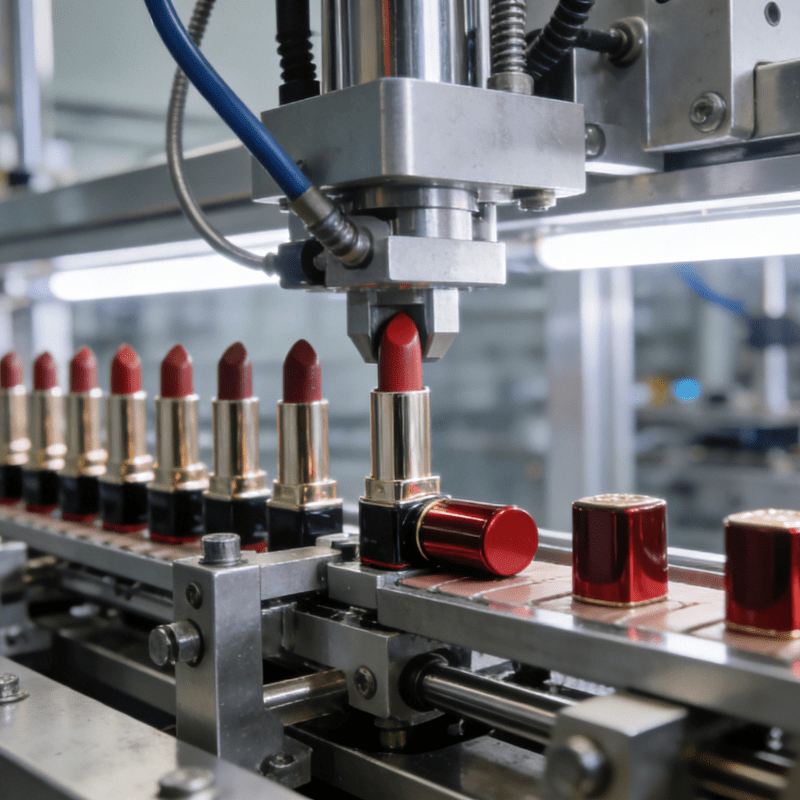

In the fast-paced cosmetic industry, production efficiency directly determines a brand’s market competitiveness—especially for eyebrow pencil manufacturing, where traditional manual assembly has long been a bottleneck: low speed, high error rates, and heavy labor dependence. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has been committed to solving these pain points. Its high-performance Eyebrow Pencil Assembly Machine is not just a production tool, but a key driver that transforms cosmetic production efficiency, helping factories break through limitations and achieve leapfrog development.

Eliminating Inefficiencies at the Core

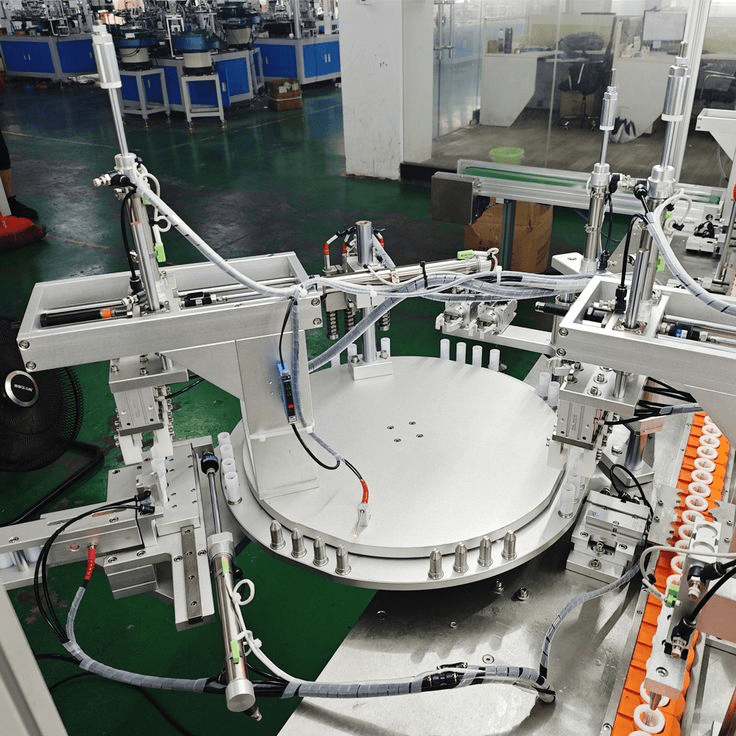

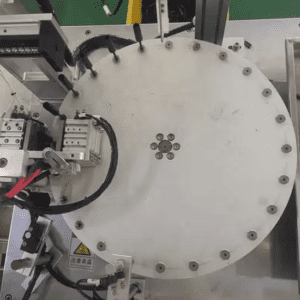

The most obvious transformation brought by the eyebrow pencil assembly machine is replacing manual labor with full automation, fundamentally solving the inefficiency of traditional production. Manual assembly requires skilled workers to complete core installation, shell fitting, and inspection step by step, with a speed of only 10-20 pieces per minute and an error rate of up to 8%. In contrast, Ruizhi’s Eyebrow Pencil Assembly Machine integrates all processes into one, achieving a production speed of 50-70 pieces per minute and reducing the error rate to less than 0.5%. One machine can replace 5-8 workers, not only saving labor costs but also avoiding errors caused by manual fatigue, ensuring consistent product quality while doubling production efficiency.

Adapting to Diverse Needs Without Efficiency Loss

Cosmetic factories often face diverse production needs—different types of eyebrow pencils (wooden, twist-up, liquid) require different assembly processes, which standard machines cannot meet. As a non-standard automation expert, Ruizhi Intelligent Manufacturing’s Eyebrow Pencil Assembly Machine supports flexible customization. Our R&D team tailors exclusive solutions according to customers’ specific requirements, such as adjusting the machine for different pencil diameters, lengths, or assembly steps. This customization capability ensures that the machine can adapt to both large-scale mass production and small-batch customized orders, eliminating the efficiency loss caused by incompatible equipment and maximizing production potential.

Sustaining High Efficiency in Long-Term Operation

True efficiency transformation requires not only high speed but also long-term stability. Ruizhi’s Eyebrow Pencil Assembly Machine is equipped with an advanced intelligent control system, which can realize real-time monitoring, fault alarm, and automatic adjustment, reducing manual intervention and equipment downtime. The machine adopts high-quality core components and undergoes strict quality testing, with a stable operation rate of over 98% and easy maintenance. In addition, Ruizhi provides one-stop after-sales service, including on-site installation, operation training, and timely maintenance support, ensuring that the machine maintains high efficiency for a long time and brings sustained value to customers.

In conclusion, Ruizhi Intelligent Manufacturing’s Eyebrow Pencil Assembly Machine transforms cosmetic production efficiency from three core aspects: automatic operation, non-standard customization, and intelligent stability. It helps cosmetic factories get rid of labor dependence, adapt to market changes, and gain a competitive edge. Choose Ruizhi, and let professional non-standard automation technology empower your eyebrow pencil production.