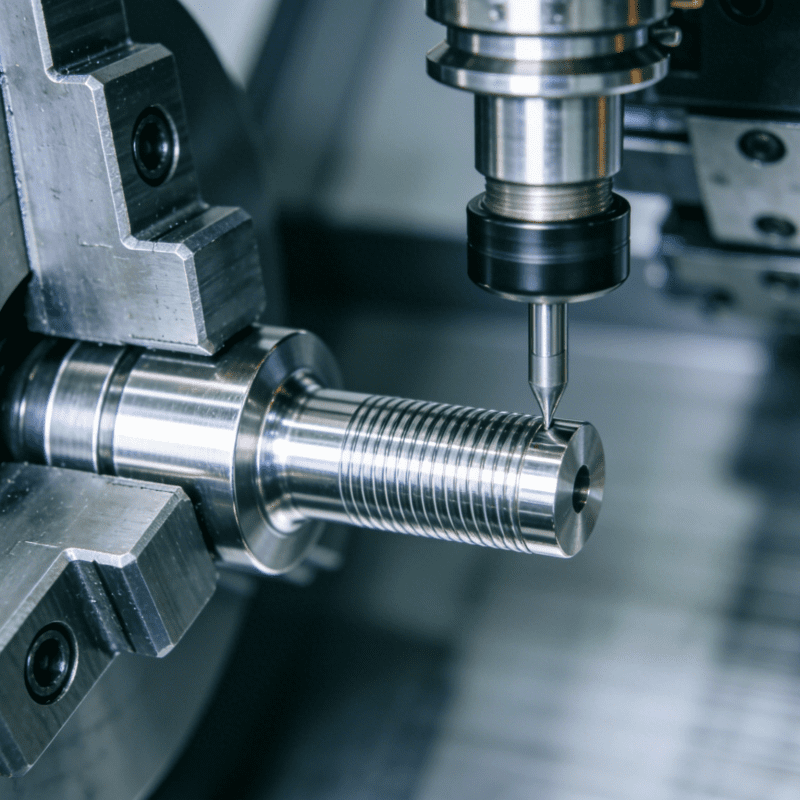

Against the background of accelerated evolution in the manufacturing industry, CNC (smart machining), as a core part of precision manufacturing, is undergoing a profound transformation from traditional models to intelligent manufacturing. Driven by digitalization, key technologies such as the Internet of Things (IoT) and Digital Twin have become critical enablers, helping enterprises break down equipment silos, achieve efficient interconnection, and implement real-time monitoring. Traditional machining is often limited by manual operation and low visibility, while intelligent transformation improves overall efficiency through data integration, laying the foundation for subsequent production optimization.

Digital Twin Visualization

Digital Twin technology provides core support for visualization in smart machining. By building an accurate digital replica of physical equipment, production lines, and even entire workshops in a virtual space, it achieves unprecedented transparency in the manufacturing process. Real-time physical data collected by sensors—including equipment status, tool wear, workpiece position, temperature, and vibration parameters—continuously update the Digital Twin model. This allows managers to intuitively monitor the dynamic operation of the entire smart machining process as if they were on-site.

Furthermore, such high-fidelity visualization is not limited to real-time status display; more importantly, it provides a solid foundation for simulation, prediction, and optimization. For example, operators can verify machining programs for complex parts in advance in a virtual environment or simulate the effects of different production scheduling strategies, identifying potential issues and optimizing decisions before physical execution, effectively shortening commissioning time and reducing trial-and-error costs. In precision manufacturing enterprises, Digital Twin-based visualization platforms have become a key technical tool for improving process control accuracy and response speed.

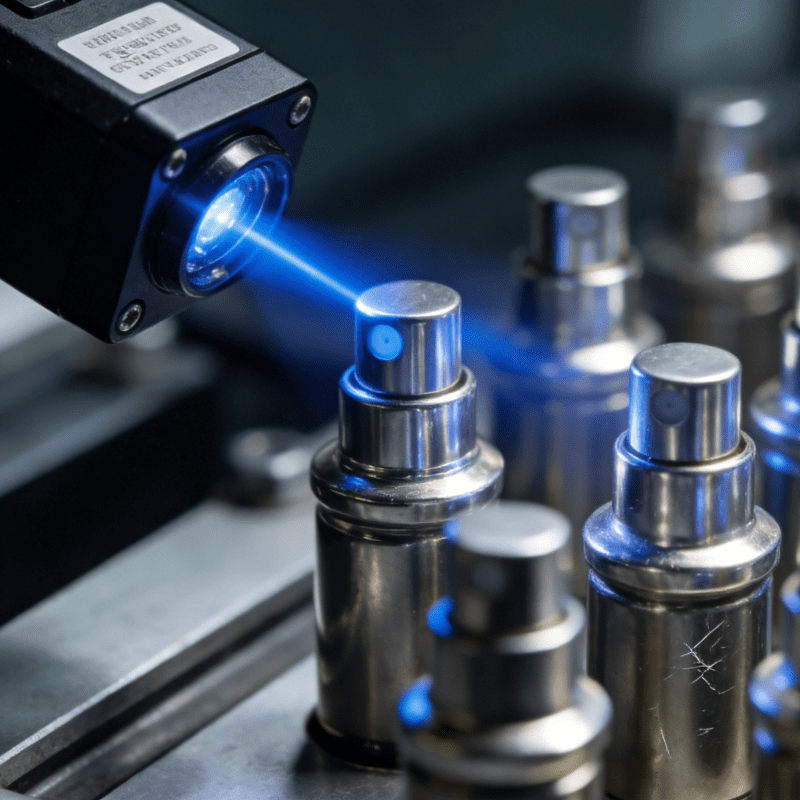

AI-Driven Intelligent Quality Control

After achieving production process visualization, AI-driven intelligent quality control becomes a critical link to ensure the precision of smart machining. Using computer vision and machine learning algorithms, intelligent inspection systems can capture and compare real-time images of finished components at millisecond speed. Compared with traditional manual sampling or contact measurement, this non-contact inspection is not only faster but also enables 100% full inspection, significantly reducing the risk of missed detection.

The built-in deep learning model can actively identify subtle quality fluctuation trends and even predict potential defects by continuously analyzing massive machining data. For instance, after deploying such a system on its intelligent precision mold production line, a major home appliance manufacturer increased the pass rate of key dimensions to over 98% while reducing labor costs in quality inspection by nearly 40%. Meanwhile, real-time quality analysis reports are directly fed back to the production control system, providing data support for instant optimization of process parameters.

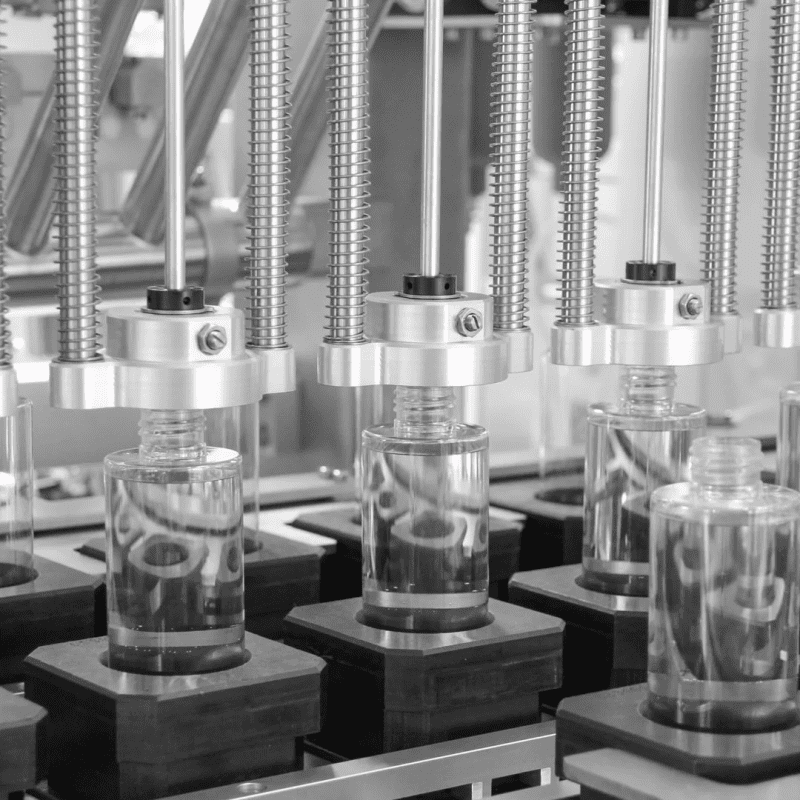

Flexible Manufacturing System

In the intelligent manufacturing transformation of smart machining, Flexible Manufacturing Systems (FMS) significantly improve the adaptability of production lines through modular design and intelligent control technology. The system uses IoT to achieve seamless connection between equipment, enabling intelligent machine tools to quickly switch machining tasks and flexibly respond to small-batch customized demands.

Through automated scheduling and parameter optimization, enterprises reduce product changeover time and improve equipment utilization. Combined with Digital Twin technology, production changes can be verified in advance in a virtual environment, further optimizing resource allocation. This dynamic adjustment mechanism not only supports diversified order processing but also lays a technical foundation for subsequent cloud collaborative manufacturing, helping to improve overall efficiency.

Cloud Collaborative Manufacturing

Based on flexible production systems, Cloud Collaborative Manufacturing integrates data from smart machining equipment through cloud computing platforms, enabling cross-regional remote monitoring and real-time collaboration. Enterprises build a unified cloud system to centrally manage multi-factory production plans, optimize resource scheduling, and promote collaborative decision-making among design, production, and supply chains.

The deployed cloud collaboration scheme supports real-time data sharing, allowing intelligent equipment in different factories to link efficiently, significantly shortening order response time and reducing logistics costs. This model not only improves information transparency but also provides scalable technical support for intelligent manufacturing transformation.

Win-Win: Efficiency and Cost Optimization

The combined effect of a series of digital transformation measures—equipment interconnection, production process visualization, AI quality control, flexible production systems, and cloud collaborative manufacturing—ultimately manifests clearly in the dual goals of improved efficiency and optimized costs.

Practices by leading manufacturers show that systematic application of IoT and Digital Twin technologies to transform smart machining processes not only significantly shortens equipment downtime and optimizes machining parameters but also generally increases overall production efficiency by about 30%. At the same time, thanks to high transparency in production and real-time early warning and interception of quality defects by AI, raw material waste is greatly reduced, equipment maintenance shifts from reactive to predictive, and the fast changeover advantage of flexible systems helps reduce operating costs by approximately 20%. This dual improvement in efficiency and cost brings considerable return on investment to manufacturing enterprises and lays a solid foundation for sustainable innovation.

Through the deep integration of IoT equipment interconnection, Digital Twin visualization, and other technologies, smart machining has achieved substantial breakthroughs in intelligent manufacturing transformation. Equipment interconnection and cloud collaborative manufacturing build an efficient production network, while AI quality control and flexible manufacturing systems enhance process flexibility, jointly driving significant improvements in production efficiency.

Case studies from enterprises such as Sany Heavy Industry and Gree Electric confirm that this digital transformation not only achieves a 30% increase in production efficiency and a 20% reduction in operating costs but also provides a replicable technical framework for manufacturing upgrading. In the future, continuous optimization of these paths will further enhance the intelligence level of smart machining and help the industry move toward higher-level sustainable development.