In the field of CNC (Computer Numerical Control) machining, the pursuit of precision in CNC precision machining has always been a key driving force for the development of the industry. Among related concepts, “zero tolerance” is often mentioned—but is it a perfect pursuit for practitioners, or an unrealistic fantasy? In-depth exploration of this question is crucial for understanding the development direction and potential of CNC precision machining.

CNC precision machining aims to produce high-precision parts and is widely used in fields with extremely high precision requirements, such as aerospace, automobile manufacturing, and medical equipment. In precision part machining, tolerance control is one of the core indicators for measuring machining quality. Tolerance, simply put, refers to the allowable variation in the size and geometric shape of a part. Zero tolerance, by contrast, means that the actual size of a part is completely consistent with the designed size, with no deviation whatsoever.

Theoretical Significance: Zero Tolerance as a Perfect Pursuit

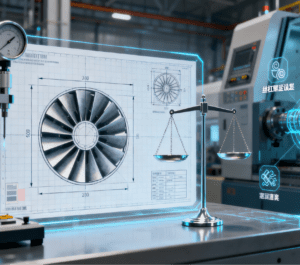

From a theoretical perspective, zero tolerance is undoubtedly an ideal state. In some scenarios with nearly harsh precision requirements—such as the manufacturing of aero-engine blades—parts operate in extremely complex environments, enduring stress from high temperatures, high pressures, and high-speed rotation. Even a tiny dimensional deviation may affect the aerodynamic performance of the blades, thereby endangering the safety and efficiency of the engine.

In such cases, the pursuit of zero tolerance ensures the consistency and reliability of parts, and enhances the overall performance of the product. From this perspective, zero tolerance is a perfect pursuit that drives the continuous advancement of CNC precision machining technology.

Practical Dilemmas: Why Zero Tolerance Seems Unrealistic

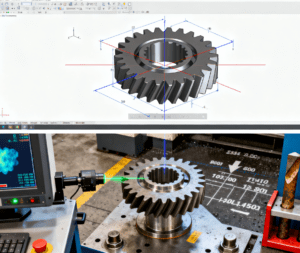

However, in actual CNC precision machining processes, achieving zero tolerance faces numerous challenges, making it seem like an unrealistic fantasy. The precision limitations of machine tools are the primary difficulty. Although the precision of modern CNC machining equipment has reached the micron or even nanometer level, it is still impossible to completely eliminate mechanical errors. For example, due to limitations in manufacturing processes and materials, the lead screws of machine tools inevitably have tiny pitch errors during operation, which directly affects the machining dimensional accuracy of parts.

Tool wear is another factor that cannot be ignored. During long-term cutting, tools will inevitably wear out, causing changes in cutting dimensions and making it difficult to maintain absolute zero tolerance. In addition, the stability of the machining environment also plays a key role in tolerance control. Minor fluctuations in temperature and humidity can cause thermal expansion and contraction of workpieces and machine tools, thereby affecting machining precision.

Even in precision part machining workshops equipped with constant temperature and humidity control systems, it is difficult to completely eliminate the impact of environmental factors. Furthermore, the skill level of operators and the standardization of their operations also affect machining precision. Differences in how different operators set and adjust machining parameters increase the difficulty of achieving zero tolerance.

Technological Breakthroughs: Gradually Approaching Zero Tolerance

Despite the numerous difficulties in achieving zero tolerance, this does not mean we should abandon the pursuit of it. With the continuous advancement of science and technology, new machining technologies and processes are constantly emerging. For instance, the adoption of special machining methods such as laser machining and electron beam machining can break through the precision limitations of traditional mechanical machining to a certain extent.

At the same time, the application of high-precision testing equipment and real-time monitoring systems makes it possible to detect deviations in the machining process in a timely manner and make real-time adjustments. A typical example is the production of medical catheters: after CNC precision machining shapes the catheter’s ultra-thin tube body and functional lumens with sub-micron accuracy, advanced catheter assembly machines integrate vision positioning, force-sensitive feedback, and CNC system data synchronization to complete the precise assembly of components such as guide wires, valves, and sensors. These machines automatically compensate for tiny positional deviations during assembly, avoiding cumulative errors that could compromise the catheter’s intravascular compatibility and functional reliability—effectively bridging the gap between CNC machining precision and zero-tolerance requirements for medical devices. By continuously improving the design and manufacturing processes of machine tools, enhancing the wear resistance and stability of tools, optimizing machining environment control, and strengthening operator training, CNC precision machining is gradually moving toward the goal of zero tolerance.

Zero tolerance in CNC precision machining is both a perfect pursuit and an extremely challenging goal. Although achieving it faces many difficulties at this stage, it points out the direction for the development of the industry. Through continuous technological innovation and process improvement, we have reason to believe that one day in the future, zero tolerance may no longer be an unreachable fantasy, but a goal that can be realized in actual production—bringing broader development space to the field of CNC machining.