In the workshops of automotive stamping, aerospace component processing, and precision mold manufacturing, irregular-shaped metal parts—such as curved engine brackets, porous turbine blades, and jagged mold inserts—have long been a “bottleneck” in automated production. Their uneven contours, sharp edges, and variable weights make manual removal not only inefficient and error-prone but also pose risks of scratches or operator injuries. The emergence of the Robotic Irregular-Shaped Metal Part Removal System (RISMPRS) has revolutionized this scenario. By integrating “adaptive vision + flexible manipulation + intelligent decision-making,” it has become a key link in realizing full-process automation for complex metal components, redefining the standards for handling non-standard parts in smart factories.

The “Triple Challenge” of Irregular Metal Part Removal: Why Robots Are Needed

Irregular-shaped metal parts differ fundamentally from regular workpieces (such as flat plates or cylinders) in three core pain points that traditional automation struggles to address:

Shape Complexity vs. Recognition Difficulty

Parts with arbitrary curves, asymmetric holes, or protruding structures (e.g., automotive differential housings with multiple flange edges) cannot be accurately positioned using conventional fixed sensors. Manual removal relies on visual inspection and experience, leading to positioning errors of up to 5-10mm, which disrupt subsequent assembly processes.

Surface Unpredictability vs. Handling Risks

Cast or forged irregular parts often have burrs, flash, or uneven hardness. Rigid robotic grippers may slip during removal or scratch precision surfaces (e.g., aerospace aluminum alloy structural parts with Ra 0.8μm finishes), resulting in scrap rates as high as 3% in manual operations.

Variable Weights vs. Efficiency Bottlenecks

From lightweight 0.5kg sheet metal brackets to heavy 50kg mold cores, irregular parts lack uniform weight standards. Manual handling requires frequent shifts, limiting throughput to 20-30 pieces per hour, while semi-automatic equipment struggles to adapt to weight fluctuations, leading to frequent shutdowns.

RISMPRS targets these pain points, leveraging technological integration to achieve “recognition-Handling-transport” closed-loop automation, turning “unpredictable irregularity” into “controllable precision.”

Core Technologies: How Robots “Tame” Irregular Shapes

The system’s ability to handle complex metal parts stems from the synergy of three core technologies, forming a “perception-execution-decision” intelligent chain:

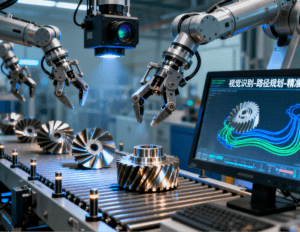

Adaptive Vision Recognition: “Seeing” the Nuances of Irregularity

Traditional 2D vision fails to capture the 3D contours of irregular parts, while RISMPRS adopts a “multi-sensor fusion” scheme:

A 3D structured light camera (with 0.02mm point cloud precision) scans the part’s surface to reconstruct a full 3D model, identifying key features such as concave holes, convex edges, and center of gravity.

Infrared sensors detect surface temperature differences (e.g., distinguishing freshly stamped hot parts from cold workpieces) to avoid thermal damage to grippers.

AI algorithms trained on 10,000+ irregular part samples classify shapes in real time (accuracy >99.5%), even for parts with missing features (e.g., partially worn gears), ensuring stable recognition.

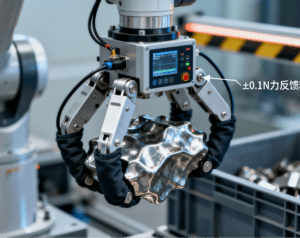

Flexible End Effector: “Grasping” with Precision and Safety

To address diverse shapes and surfaces, the system’s end effector features modular and adaptive design:

Magnetic grippers with adjustable suction (5-500N) handle ferrous parts (e.g., iron castings), with soft rubber pads to prevent scratches.

Vacuum suction cups with variable air pressure (0.3-0.8MPa) adapt to non-magnetic materials like aluminum alloys, using multi-point suction (up to 12 independently controlled cups) to grip curved surfaces without deformation.

For parts with special structures (e.g., turbine blades with tenons), custom-designed “jaw + support” combined grippers use force sensors (precision ±0.1N) to adjust clamping force, avoiding over-squeezing while ensuring a secure grip.

Dynamic Path Planning: “Moving” Without Collision

Irregular parts often require navigation through cluttered environments (e.g., dense stacks in warehouses or narrow gaps in stamping lines). RISMPRS uses a “predictive trajectory algorithm”:

Based on the 3D model, the system pre-simulates 5-8 possible removal paths, prioritizing those with the shortest distance and least collision risk.

During movement, a laser radar (scanning frequency 10Hz) monitors the environment in real time; if an unexpected obstacle (e.g., a misplaced tool) is detected, the path is re-planned within 0.5 seconds.

For heavy parts, the algorithm optimizes the mechanical arm’s motion speed (0.1-1m/s adjustable) to reduce inertia, ensuring stable transport even for eccentrically weighted workpieces.

Application Scenarios: From Workshop to Smart Factory

In industries with high demands for irregular metal parts, RISMPRS has proven its value through tangible efficiency gains:

Automotive Stamping: Breaking Free from “Heavy Labor”

In a domestic automotive OEM’s stamping workshop, irregular-shaped fenders (with curved edges and multiple mounting holes) were previously removed manually, with 2 workers handling 120 pieces per shift, and a 2% scratch rate. After adopting RISMPRS:

The system recognizes fender contours in 0.8 seconds, uses vacuum suction cups with soft pads to grip, and transfers them to the next station via an optimized path.

Throughput increased to 300 pieces per shift (2.5x improvement), with scratch rate reduced to 0.1%, saving $120,000 annually in rework costs.

Aerospace Component Processing: Protecting “High-Value Precision”

Aero-engine turbine blades (with complex airfoil curves and tenon structures) require damage-free handling. RISMPRS uses 3D vision to locate the tenon, then employs a custom jaw gripper with force feedback to clamp gently (force controlled at 5±0.2N), ensuring no deformation of the 0.5mm-thick blade edges.

Compared to manual handling (which risked 1-2 damaged blades per batch of 100), the system achieved zero defects, reducing scrap losses by $500,000/year for high-value titanium alloy blades.

Mold Manufacturing: Adapting to “Diverse Specifications”

A mold factory producing 500+ types of irregular mold inserts (weights 1-30kg) faced frequent changeover delays. RISMPRS solved this with:

Quick-change grippers (magnetic to vacuum in 30 seconds) and a pre-stored database of insert 3D models.

Changeover time between different inserts reduced from 40 minutes (manual adjustment) to 2 minutes, enabling small-batch, multi-variety production to meet flexible order demands.

Future Evolution: Toward “Self-Evolving” Intelligent Handling

As smart manufacturing advances, RISMPRS is moving beyond “single-task automation” to become a core node in the industrial internet:

AI Self-Learning

By accumulating data on handling success rates, gripper wear, and path efficiency, the system will autonomously optimize parameters—e.g., increasing suction by 10% for parts with oily surfaces or adjusting grip points for frequently slipped workpieces—reducing manual intervention by 80%.

Multi-Robot Collaboration

In large workshops, 2-4 RISMPRS units will coordinate via 5G, dividing labor by part weight or complexity (e.g., lightweight robots handle small brackets, heavy-duty robots manage mold cores), improving overall throughput by 30% compared to single-robot systems.

Green Energy Integration

Adopting energy-recuperative servo motors and low-power 3D cameras, the system will reduce energy consumption by 25%, aligning with manufacturing’s “carbon neutrality” goals while maintaining high precision.

From curved automotive parts to intricate aerospace components, Robotic Irregular-Shaped Metal Part Removal Systems are not just replacing manual labor—they are rewriting the rules of handling complex metal parts. By turning “irregularity” into a manageable variable, they bridge the gap between traditional manufacturing and full automation, proving that in the era of intelligence, even the most “unruly” workpieces can be tamed by technology. As industries demand higher flexibility and precision, RISMPRS will undoubtedly become a cornerstone of the next generation of smart factories.