As a core device in the daily chemical and cosmetic industries, lotion pump assembly has long been plagued by low manual efficiency, high defect rates, and difficulty adapting to multi-spec production. Ruizhi Intelligent Manufacturing’s automatic lotion pump assembly equipment breaks these bottlenecks, integrating high precision, flexibility, and stability to provide professional solutions for lotion pump manufacturers worldwide.

Boost Efficiency & Qualification Rate

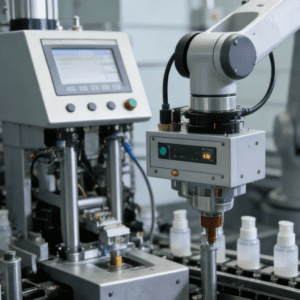

Equipped with PLC control systems and high-precision servo motors, our equipment realizes fully automated assembly of 5-7 piece lotion pump components, including pump shells, springs, pistons, and locking caps. Adopting circular slide rail conveying and secondary positioning technology, it ensures assembly accuracy within ±0.1mm, with a stable output of 1500-2500 pieces per hour . Each station is equipped with real-time detection modules to automatically identify missing parts, misalignment, and air leakage, boosting the qualification rate to over 98%. The integrated automatic silicone oil coating function optimizes pump smoothness, while sound insulation covers reduce operational noise, improving workshop environment.

Adapt to Multi-Spec Demands

Ruizhi excels in non-standard customization to meet diverse production needs. Our equipment widely adapts to lotion pumps with neck sizes of 20mm, 24mm, 28mm, and 32mm , supporting both standard round pumps and special-shaped anti-leakage pumps. Modular quick-change fixtures allow mold switching in 10 minutes without professional tools, easily handling small-batch, multi-SKU production. For high-end demands, we offer customized functions such as airtightness testing and anti-scratch clamping, fully matching the production characteristics of cosmetics, hand sanitizers, and medical liquids.

Ensure Long-Term Production Reliability

Constructed with 304 stainless steel and food-grade seals, the equipment complies with FDA and GMP standards, avoiding material contamination and facilitating daily cleaning . Core components adopt well-known brand parts, ensuring a trouble-free operation rate of over 98% and a service life of more than 5 years. It seamlessly integrates with upstream injection molding and downstream filling lines, forming a complete production chain. Ruizhi provides one-stop services including pre-delivery debugging, on-site training, and spare parts supply, safeguarding continuous production for customers.

Ruizhi’s automatic lotion pump assembly equipment balances automation and customization, helping enterprises reduce labor costs by over 80% while enhancing product consistency. It has become a trusted choice for daily chemical manufacturers pursuing efficient, high-quality production.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine