Table of Contents

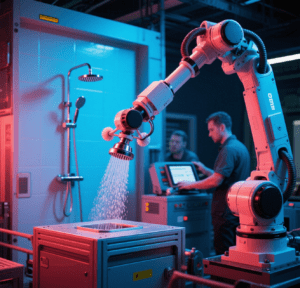

Toggle6-Axis Robotic Showerhead Loading/Unloading System: Mastering Complexity in Manufacturing

In the intricate world of showerhead production—where curved surfaces, threaded connectors, and varied geometries demand precise handling—manual loading/unloading is a bottleneck riddled with inefficiencies. Human operators struggle with repetitive motions, inconsistent positioning, and the risk of ergonomic injuries, while traditional 4-axis systems fall short in managing the 3D complexity of showerhead designs. Enter the 6-Axis Robotic Showerhead Loading/Unloading System—a versatile solution engineered to tackle these challenges with unmatched dexterity, adaptability, and speed. Designed for 卫浴 factories, plumbing manufacturers, and assembly lines, this system transforms a once-laborious process into a streamlined, high-precision operation.

Why 6-Axis? The Necessity of Full 3D Dexterity

Showerheads are rarely flat or symmetrical—their angled nozzles, curved handles, and threaded interfaces require 6 degrees of freedom for optimal handling. Here’s why 6-axis robots excel where others fail:

1. Unlimited Orientation Control

Unlike 4-axis SCARA robots (limited to planar motion), 6-axis arms rotate freely around all axes, enabling:

- Angled Pickup: Grasp showerheads at 45° from conveyor belts or storage racks.

- Thread Alignment: Position threaded connectors with ±0.1° rotational accuracy for seamless assembly into valves or hoses.

2. Heavy-Duty Flexibility

With payload capacities up to 10kg (ideal for metal showerheads with integrated valves) and reach spans of 800–1500mm, 6-axis systems handle both lightweight plastic models and heavy-duty brass units without tool changes.

3. Complex Path Navigation

Maneuver around fixtures, sensors, or other robots in tight workcells, thanks to advanced inverse kinematics that calculate collision-free trajectories in milliseconds.

Core Technologies: The DNA of a Smart Loading System

1. 3D Vision-Guided Localization

A stereo vision system paired with AI-powered depth sensing solves the chaos of showerhead orientation:

- Chaotic Bin Picking: Identifies showerheads buried in bulk bins, even when stacked or tangled, with 99.5% accuracy.

- Real-Time Pose Estimation: Calculates both position (X-Y-Z) and orientation (roll-pitch-yaw) to within 5mm/0.5°, critical for aligning threaded parts.

Example: In a bathroom fixture factory, the system picks 200 unique showerhead models from a bin, each requiring a different grasp angle for their handle or nozzle.

2. Force-Torque Controlled Gripping

A 6-axis force-torque sensor ensures gentle yet secure handling of delicate surfaces (e.g., chrome-plated finishes) and rigid threading:

- Adaptive Pressure Control: Applies 2–15N of grip force based on part material (plastic vs. metal), preventing scratches or deformations.

- Thread Engagement Feedback: Detects resistance during insertion into assembly jigs, adjusting torque in real time to avoid cross-threading (a common manual error).

3. Modular End-of-Arm Tooling (EOAT)

Quick-release grippers adapt to diverse showerhead designs in <10 minutes:

- Hybrid Grippers: Combine vacuum suction (for smooth surfaces) and mechanical fingers (for textured handles) in a single tool.

- Magnetic Collars: Securely hold metal showerheads without marking, ideal for hot-forged brass components.

- Tool Library: Stores 50+ gripper configurations, enabling rapid 切换 between rainfall showerheads, handheld models, and wall-mounted units.

4. Smart Production Scheduling Software

Integrates with MES systems to:

- Optimize Batch Sequences: Prioritizes high-mix production runs, reducing changeover time by 40% compared to manual scheduling.

- Predictive Maintenance: Monitors joint wear and gripper fatigue, scheduling service during planned downtime to achieve 98% uptime.

Transforming 卫浴 Production: Applications in Action

1. Showerhead Forging & Machining Lines

In a brass forging plant:

- Loading CNC Machines: The robot picks raw brass billets (5kg each) from pallets, orienting them for precision drilling of water channels.

- Unloading Finished Parts: Removes machined showerheads from fixtures, using vision to inspect for drilling errors before sending them to plating.

Result: Cycle time per part drops from 120 seconds (manual) to 45 seconds, with zero misloading errors—a 60% productivity leap.

2. Assembly & Quality Control

In a final assembly line for handheld showerheads:

- Inserting Valves: The robot aligns a 30° angled valve into the showerhead body with ±0.05mm linear and ±0.2° angular accuracy.

- Leak Testing Loading: Places assembled units onto pressure-testing jigs, ensuring the threaded inlet mates perfectly with the tester—eliminating false positives from misalignment.

Case Study: A leading 卫浴 brand reduces assembly defects from 8% to 1.2%, saving $500k annually in rework costs.

3. Logistics & Palletizing

For shipping large rain showerheads (300mm diameter) to distribution centers:

- Irregular Stacking: The robot adapts to the circular shape, placing each unit into corrugated trays with 20mm clearance—impossible for 4-axis systems.

- Mixed SKU Palletizing: Builds pallets with 5+ showerhead models in a single run, guided by WMS data for optimal load stability.

6-Axis vs. Traditional Methods: A Performance Breakdown

| Metric | 6-Axis Robotic System | Manual Handling | 4-Axis Robot | Conventional Gantry |

| 3D Orientation Control | Yes (6DOF) | Limited (2–3DOF) | No (4DOF) | No (3DOF, rigid) |

| Cycle Time (per part) | 20–30 seconds | 60–90 seconds | 40–50 seconds | 50–60 seconds |

| Positioning Accuracy | ±0.1mm/±0.5° | ±1mm/±5° (variable) | ±0.05mm (planar only) | ±0.5mm/±2° |

| Changeover Time | <15 minutes | 60+ minutes | 30 minutes | 120+ minutes |

| Cost (USD) | $150k–$300k | Labor-intensive | $80k–$150k (limited to simple shapes) | $200k–$400k (inflexible) |

The Business Case: From Labor Pain to Profit Gain

1. Rapid ROI Through Efficiency

- Labor Reduction: Replaces 3–5 operators per line, saving $70k–$100k annually in regions with moderate labor costs.

- Quality Assurance: 90% fewer misaligned parts mean fewer failed pressure tests and rework, critical for meeting ISO 9001 standards.

- Scalability: Handles 24/7 production with minimal supervision, supporting just-in-time delivery for global 卫浴 brands.

2. Future-Ready Manufacturing

- AI-Driven Optimization: Machine learning refines pick-and-place paths based on real-time data, shaving 5–10% off cycle times over 6 months.

- Collaborative Safety: Equipped with 3D safety scanners, works alongside humans in shared workcells—ideal for hybrid manual-automated lines.

- Data Traceability: Logs every handling action (force applied, position, timestamp) for end-to-end quality audits, critical for regulatory compliance (e.g., NSF/ANSI 61 for drinking water systems).

The Next Generation: Where Dexterity Meets Intelligence

As 卫浴 manufacturing trends toward mass customization (think modular showerheads with interchangeable nozzles), the 6-axis system evolves with:

- Self-Calibrating Grippers: Auto-detect part dimensions using on-tool sensors, eliminating manual setup for new SKUs.

- Edge Computing Integration: Processes vision data locally for sub-millisecond decision-making, essential for high-speed, mixed-model production.

- Sustainability Features: Energy-recovery systems reduce power consumption by 25%, aligning with global green manufacturing goals.

In an industry where precision and flexibility are non-negotiable, the 6-Axis Robotic Showerhead Loading/Unloading System is more than a machine—it’s a strategic partner. It turns the complexity of showerhead production into a competitive advantage, enabling manufacturers to build better products faster, with fewer errors, and lower costs.

#6Axis Showerhead Robotics #Automated Bathroom Fixture Handling #Precision Manufacturing Solutions