Table of Contents

Togglehe Rise of Agentic AI: Revolutionizing Intelligent Automation with a Strategic Triad

In an era where technological advancements are reshaping industries at an unprecedented pace, agentic AI emerges as a transformative force in the realm of intelligent automation. This cutting-edge technology isn’t just another incremental step forward; it represents a paradigm shift with the potential to redefine how businesses operate across diverse sectors. From streamlining customer support to revolutionizing complex manufacturing processes, agentic AI’s capabilities extend far beyond traditional automation, promising significant cost savings, enhanced quality, and elevated customer satisfaction. Nowhere is this potential more evident than in the manufacturing of bathroom fixtures, where the integration of agentic AI into the operations of Sanitary Ware Automatic Assembly Machines for Bathroom Fixture Assembly could mark a new era of efficiency and innovation.

But leap to what? And transform how?

Agentic AI can reduce the cost of customer support by 25 – 50% while dramatically improving quality and customer satisfaction because it goes beyond simple task execution. It can also autonomously resolve complex workflows and customer interactions. When applied to customer support, for example, agents don’t just respond to queries but comprehensively resolve inquiries from start to finish, reducing human intervention and increasing efficiency. This transformative potential extends far beyond customer support. In the manufacturing sector, agentic AI holds the key to revolutionizing processes, especially those involved in the intricate production of bathroom fixtures.

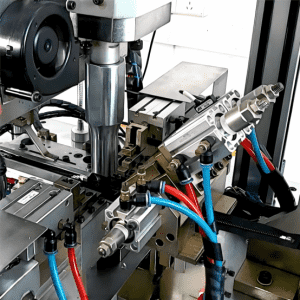

In factories utilizing Sanitary Ware Automatic Assembly Machines for Bathroom Fixture Assembly, agentic AI can optimize operations with remarkable precision. It acts as a vigilant supervisor, monitoring the assembly lines in real-time, and leveraging predictive analytics to foresee potential bottlenecks or component shortages. By sifting through vast amounts of production data, it can suggest astute adjustments to the assembly sequence or machine settings, thereby enhancing productivity and minimizing waste. This not only streamlines the manufacturing process but also ensures that resources are utilized in the most efficient manner possible.

However, as with all groundbreaking technologies, the adoption of agentic AI comes with its own set of challenges. For companies looking to implement this technology, well-documented and thoroughly understood workflows are a prerequisite, along with a robust knowledge base that the agentic AI can draw upon. Data privacy and security concerns, similar to those associated with generative AI, require companies to have a clear understanding of the large language models (LLMs) they employ and how information is stored and transmitted. In the context of the detailed processes of Bathroom Fixture Assembly, safeguarding data related to product designs, manufacturing specifications, and customer preferences used by the agentic AI becomes of utmost importance. A breach in this sensitive information could not only disrupt production but also damage a company’s reputation.

Nevertheless, with the right adoption strategy, the path to successful intelligent automation becomes much clearer. To fully capitalize on the benefits of agentic AI, companies need to focus on three crucial aspects:

Start in the right place

Contrary to common perception, the optimal starting point isn’t with low-volume use cases. Instead, companies should begin with their highest-volume processes. While this might seem risky, when executed properly, it’s the most effective way to realize significant returns on investment. Starting small with low-volume tasks may lead to minimal impact, failing to justify the investment made in implementing agentic AI.

For manufacturers of bathroom fixtures, high-volume production runs on Sanitary Ware Automatic Assembly Machines are ideal candidates for initial agentic AI implementation. By starting with a small percentage, such as 1%, of the daily output of these machines, companies can conduct thorough tests of the AI system’s capabilities. For instance, the AI can be tasked with optimizing the movement of components on the assembly line, ensuring that parts for Bathroom Fixture Assembly reach the appropriate stations precisely when needed. This phased approach allows companies to identify and rectify any issues before scaling up the automation across the entire production process, minimizing risks and maximizing the potential benefits.

Balance agentic AI with human expertise

As companies assess their workflows for automation opportunities, they’ll find that certain tasks are best left to human oversight or direct action. While agentic AI is a highly capable innovation, it has its limitations.

In Bathroom Fixture Assembly, there are aspects that demand the human touch. Agentic AI can handle repetitive tasks like component fitting and basic quality checks on Sanitary Ware Automatic Assembly Machines with ease. However, the final aesthetic inspection of high-end bathroom fixtures requires the discerning eye of a human. Humans can perceive the subtle nuances in finish, color matching, and overall design appeal that an AI might overlook. When dealing with complex custom orders for bathroom fixtures, human designers and engineers shine, leveraging their creativity and industry knowledge to understand and translate unique customer requirements into viable products. AI can support in areas such as generating design alternatives and estimating production costs, but the human element remains irreplaceable in these more nuanced aspects.

Specifically, there are three key reasons why human expertise is essential:

- Lack of general intelligence: AI agents, including the LLMs that support them, currently lack true general intelligence. They operate most effectively in narrow, well-defined areas. Unlike humans, who can learn from one task and apply the principles to unrelated tasks, AI struggles with such abstraction.

- Complex decision matrices: Workflows involving extremely complex decision matrices that require significant experience-based judgment are better suited for human experts. For example, when innovating new designs for bathroom fixtures, understanding market trends, and maintaining brand consistency across product lines, human creativity and industry knowledge are indispensable. An AI agent can analyze market data on popular styles and colors, but it takes human insight to translate that data into a revolutionary new design for a bathroom fixture produced by a Sanitary Ware Automatic Assembly Machine.

- Emotional and communicative nuances: Workflows that rely on “messy” human communication and emotional nuance are best handled by humans. In the case of customer complaints regarding bathroom fixtures, a human customer service representative can empathize with the customer’s frustration, especially when there are issues with a newly installed product. While an AI can handle the technical aspects of diagnosing the problem and suggesting solutions, the human touch is crucial for maintaining customer satisfaction.

In practice, a hybrid model that combines the strengths of both AI and human expertise proves to be the most effective. Even when tasks are primarily handled by human experts, AI should be utilized to enhance their capabilities, providing valuable data-driven insights and assistance. In general, companies should assign transactional, repeatable tasks to agentic AI and rely on human expertise for high-stakes interactions, emotionally complex scenarios, and situations requiring nuanced judgment. In bathroom fixture manufacturing, routine tasks on the Sanitary Ware Automatic Assembly Machine, such as component sorting and basic assembly operations, can be automated, while more complex tasks like product recalls due to safety concerns or major design overhauls benefit from human-led decision-making, with AI assisting in data analysis and scenario planning.

Tap into a network of agentic expertise

Perhaps the most critical factor in successfully adopting agentic AI is not to attempt it in isolation. Establishing a network of expert partners is essential. Emerging agentic AI platforms can provide the necessary technology across digital and voice channels. Systems integrators and advisors who understand the intricacies of customer operating environments can train agentic models to meet specific customer needs and integrate them seamlessly into a company’s operations.

For companies engaged in Bathroom Fixture Assembly using Sanitary Ware Automatic Assembly Machines, partnering with AI experts who understand the complexities of manufacturing processes is vital. These partners can customize agentic AI models to fit the unique requirements of the assembly line, taking into account factors such as the variety of fixture designs, the materials used, and the existing production infrastructure. They can also assist in integrating the AI system with other factory systems, such as inventory management and quality control, creating a cohesive and efficient production ecosystem. Integrating these models into enterprise systems demands deep expertise in complex workflows, industry-specific challenges, and a nuanced understanding of workflow decision points and where human interaction is most beneficial. When done right, agentic AI becomes a powerful ally, boosting worker productivity and team efficiency.

As the landscape of AI continues to evolve at breakneck speed, the adoption of agentic AI is not just an option but a strategic imperative for businesses aiming to stay competitive. In the specialized domain of bathroom fixture manufacturing, where the precision and complexity of Sanitary Ware Automatic Assembly Machine – driven processes demand constant optimization, the right approach to implementing agentic AI can be a game-changer. By starting in the right place, striking a balance between AI and human expertise, and leveraging a network of specialized partners, companies can unlock the full potential of this technology. The journey towards intelligent automation with agentic AI is not one to be embarked upon lightly, but for those who navigate it wisely, the rewards—from improved productivity on the assembly line to enhanced customer experiences—are bound to reshape the future of manufacturing and beyond.