At its core, an assembly machine (or assembly press) is a specialized, versatile piece of equipment designed to join multiple components into a finished product or sub-assembly. Unlike generic tools, it is engineered to execute specific joining tasks with controlled precision—whether pressing, fastening, riveting, or bonding parts together.

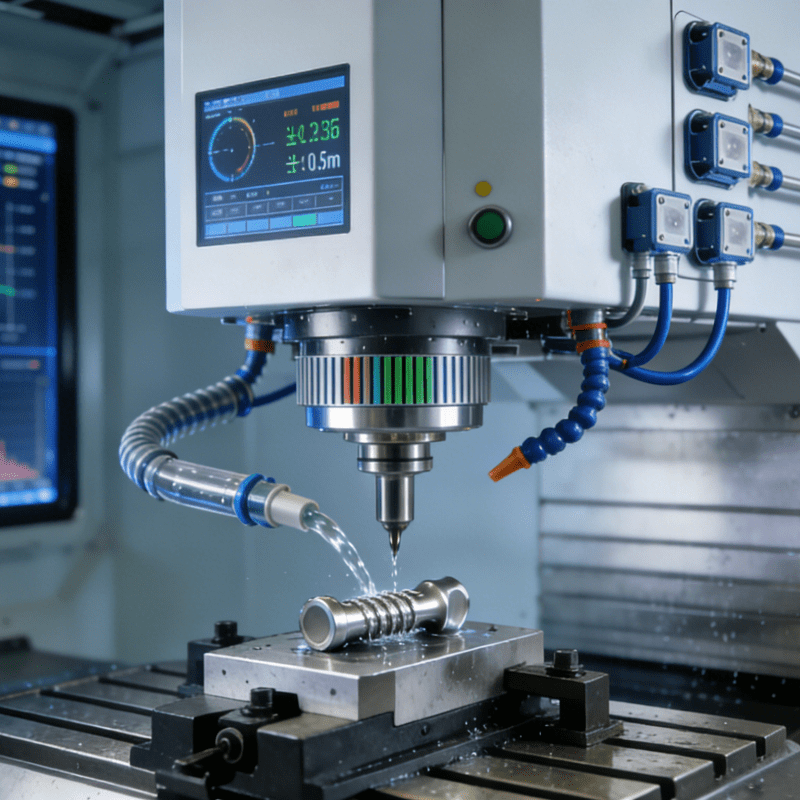

One common design variant is the ball screw press, which uses a precision ball screw mechanism to apply consistent, adjustable force (ranging from a few Newtons to thousands of Newtons) to components. For example, it might press a bearing into a motor housing or seal a connector onto a wire harness—ensuring the joint meets strict dimensional and structural standards that manual work is hard to replicate.

The Era of Manual Assembly Lines: Foundations and Limitations

Before automation, manufacturing relied heavily on manual assembly line systems—the most iconic being the conveyor belt-driven lines popularized by the automotive industry in the early 20th century. These systems organized labor into specialized tasks: one worker might attach a bolt, another insert a washer, and so on, with conveyors moving parts between stations.

While manual lines laid the groundwork for mass production, they had inherent flaws that limited scalability:

Efficiency bottlenecks: Human speed and stamina capped output—even skilled workers could only complete 80–90% of a standard production takt time before fatigue set in.

Quality inconsistency: Manual operations were prone to errors (e.g., inconsistent bolt torque, missed parts) that led to costly rework or defective products.

Labor dependence: High-volume production required large teams of trained workers, making costs volatile as labor markets shifted.

The Rise of Automated Assembly Machines: A Leap in Production Capability

The introduction of automated assembly machines addressed these limitations, marking a pivotal shift in manufacturing. These systems integrate three core technologies to redefine assembly:

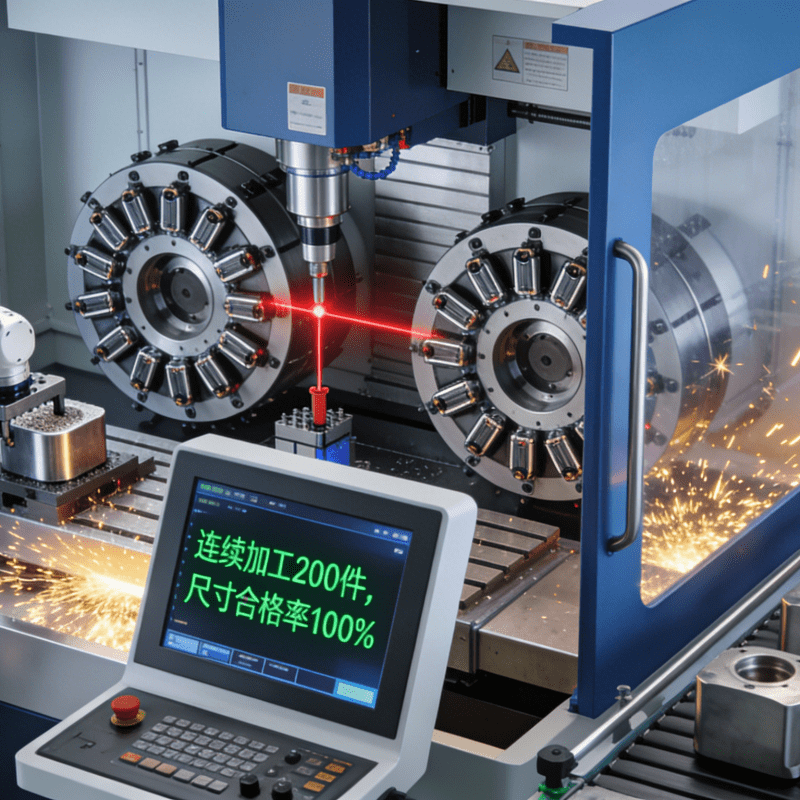

Sensors: Vision sensors (for part positioning), force sensors (for controlling press force), and proximity sensors (for safety checks) ensure every step is precise and error-free—for instance, a vision sensor can align a circuit board with a connector within ±0.01mm.

Robotic arms: Collaborative robots (cobots) or industrial robots handle repetitive, high-precision tasks—such as placing microchips on PCBs or assembling small medical components—without the need for constant human oversight. Specifically, the 4 – Axis Robotic Small Product Assembly System excels in assembling compact, intricate items like small electronic connectors, smartwatch battery modules, or miniaturized medical sensors: its 4-axis movement (combining linear and rotational motion) enables flexible access to tight spaces, while its compact structure fits easily into small-batch production lines, making it ideal for industries like consumer electronics and micro-medical devices that demand both precision and adaptability.

CNC software: Computer Numerical Control (CNC) programs store and execute assembly parameters (e.g., press force, robot movement paths) across batches, ensuring consistency even for complex, multi-step tasks.

Crucially, automated assembly machines are not just “faster manual workers”—they enable flexible production: a single machine can switch between assembling different products (e.g., three models of smartphone chargers) by updating CNC programs and swapping modular fixtures, eliminating the need for multiple dedicated lines.

Core Advantages of Automated Assembly Machines

Automated assembly machines deliver value across industries—from automotive and electronics to medical devices—by solving the most pressing pain points of traditional manufacturing:

- Consistent Quality, Minimal Errors

Automation eliminates human-related variability. For example, in automotive brake caliper assembly, an automated machine tightens bolts to a precise torque (±2 N·m) and records every data point, reducing defect rates from 1–2% (manual) to less than 0.05%. In medical device manufacturing, this precision ensures products like insulin pens meet FDA standards for safety and functionality.

- Higher Efficiency, 24/7 Operation

Unlike manual lines, automated machines operate continuously with 95%+ equipment utilization. A consumer electronics factory, for instance, can boost daily output of wireless earbud assemblies from 500 units (manual) to 2,000 units (automated)—all while reducing overtime costs and production delays.

- Lower Long-Term Costs

While initial investment is higher, automation cuts costs in three key ways:

Labor savings: A single automated line may replace 5–10 manual workers, offsetting costs within 12–18 months for high-volume production.

Waste reduction: Precision assembly minimizes material scrap (e.g., 30% less plastic part damage in toy manufacturing) and reduces rework expenses.

Reduced downtime: Predictive maintenance (powered by CNC data) alerts teams to potential issues (e.g., worn robot bearings) before they cause unplanned halts.

- Safety and Scalability

Automated machines handle high-risk tasks—such as assembling parts in high-temperature or chemical-exposed environments—reducing worker exposure to hazards. Additionally, their modular design makes scaling easy: businesses can add sensors, robots, or new program parameters to adapt to higher volumes or new product designs, without rebuilding entire lines.

Conclusion

From manual conveyor belts to sensor-equipped automated systems, assembly machines have evolved to meet the changing needs of manufacturing. Today, they are no longer just “tools”—they are strategic assets that enable businesses to balance efficiency, quality, and flexibility. As industries like electric vehicles and precision healthcare grow, automated assembly machines will continue to evolve—integrating AI for predictive optimization and digital twins for virtual testing—solidifying their role as the backbone of modern manufacturing.

Examples of Robot Automatic Assembly Lines

Advantages of Artificial Intelligence Automatic Assembly Lines