4-axis CNC machining is an advanced manufacturing technology that adds a rotary axis to traditional 3-axis CNC machining. Compared with conventional 3-axis CNC machining, 4-axis CNC machining enables more complex machining operations on workpieces while significantly improving machining efficiency and precision. This article will elaborate on the working principle, advantages, application fields and significance of 4-axis CNC machining in modern manufacturing.

Working Principle of 4-Axis CNC Machining

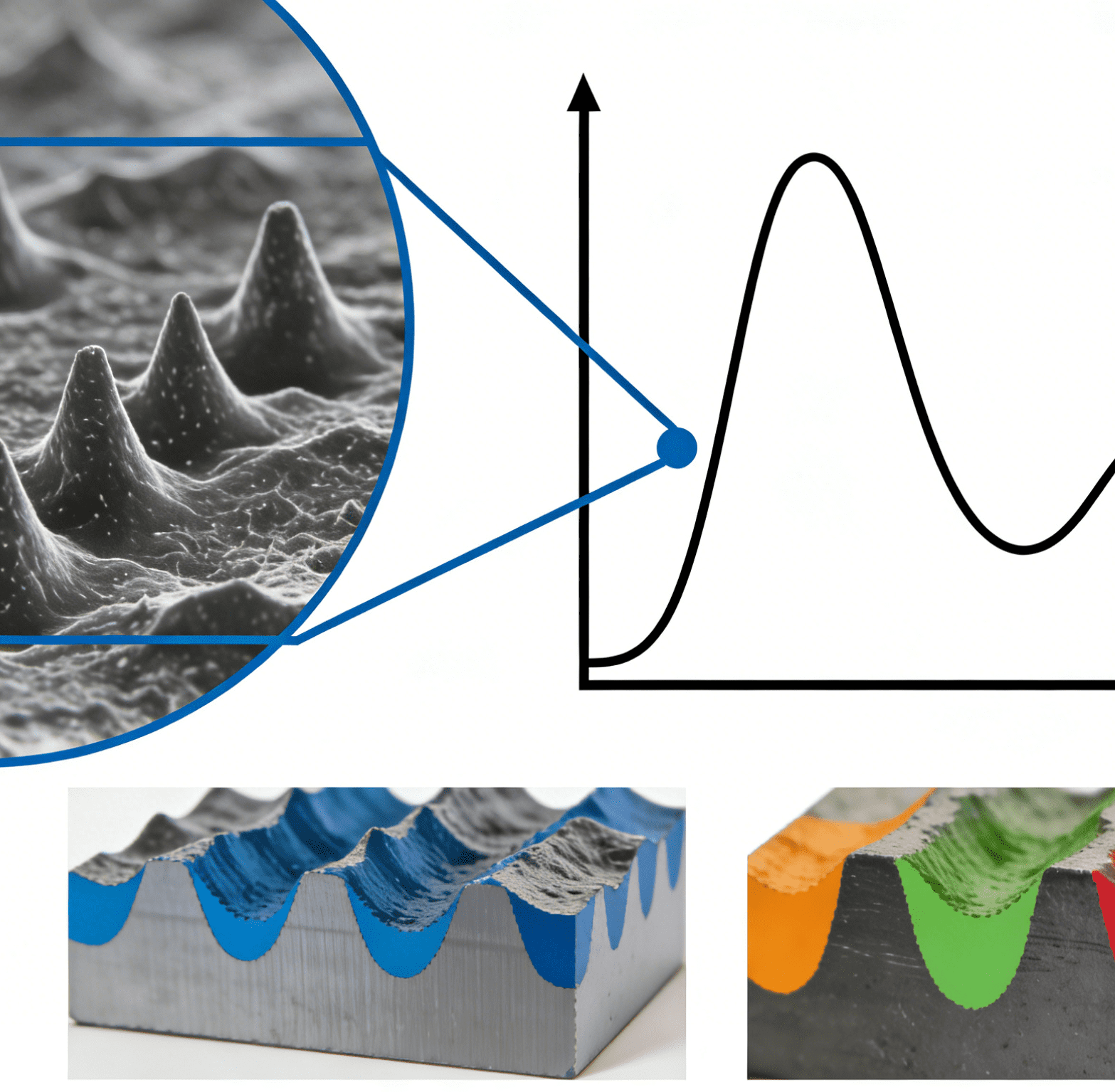

In a 3-axis CNC machining center, the cutting tool moves along the X, Y, and Z linear axes, allowing the center to perform planar and solid machining operations. However, 3-axis CNC machining has limitations when dealing with certain complex shapes. To address this issue, 4-axis CNC machining adds an extra rotary axis (usually the A-axis or B-axis), which enables either the tool or the workpiece to rotate around a specific axis, thus achieving more diversified machining operations.

The common definitions of the two rotary axes are as follows:

A-axis: Rotation around the X-axis

B-axis: Rotation around the Y-axis

With the addition of this rotary axis, 4-axis CNC machining centers can perform the following operations:

Multifunctional Machining: The workpiece can be rotated to different angles for machining, avoiding multiple setups and improving production efficiency.

Helical Machining: Machining of complex curves such as threads and helical grooves.

Bevel Machining: Machining of workpiece surfaces with bevels or angular features.

Advantages of 4-Axis CNC Machining

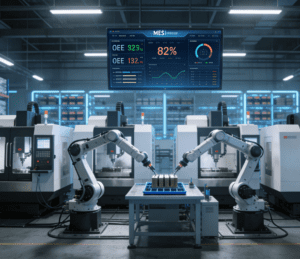

Improved Machining Efficiency:Since the workpiece can be machined from various angles, multiple surfaces can be finished in a single clamping. This reduces the time spent on multiple clamping processes and workpiece alignment.

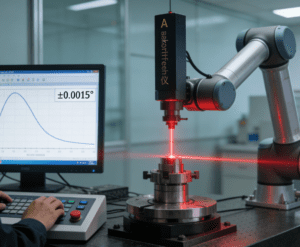

Enhanced Machining Precision:It minimizes errors caused by repeated clamping, ensuring consistent machining precision across the entire workpiece.

Expanded Machining Range:4-axis CNC machining can handle complex geometric shapes and surface features that are unattainable with 3-axis CNC machining centers, greatly expanding the range of machinable parts.

Simplified Machining Processes:The use of a rotary axis simplifies the machining steps for certain complex parts, reducing production difficulties.

Application Fields of 4-Axis CNC Machining

4-axis CNC machining is widely used in the following industries:

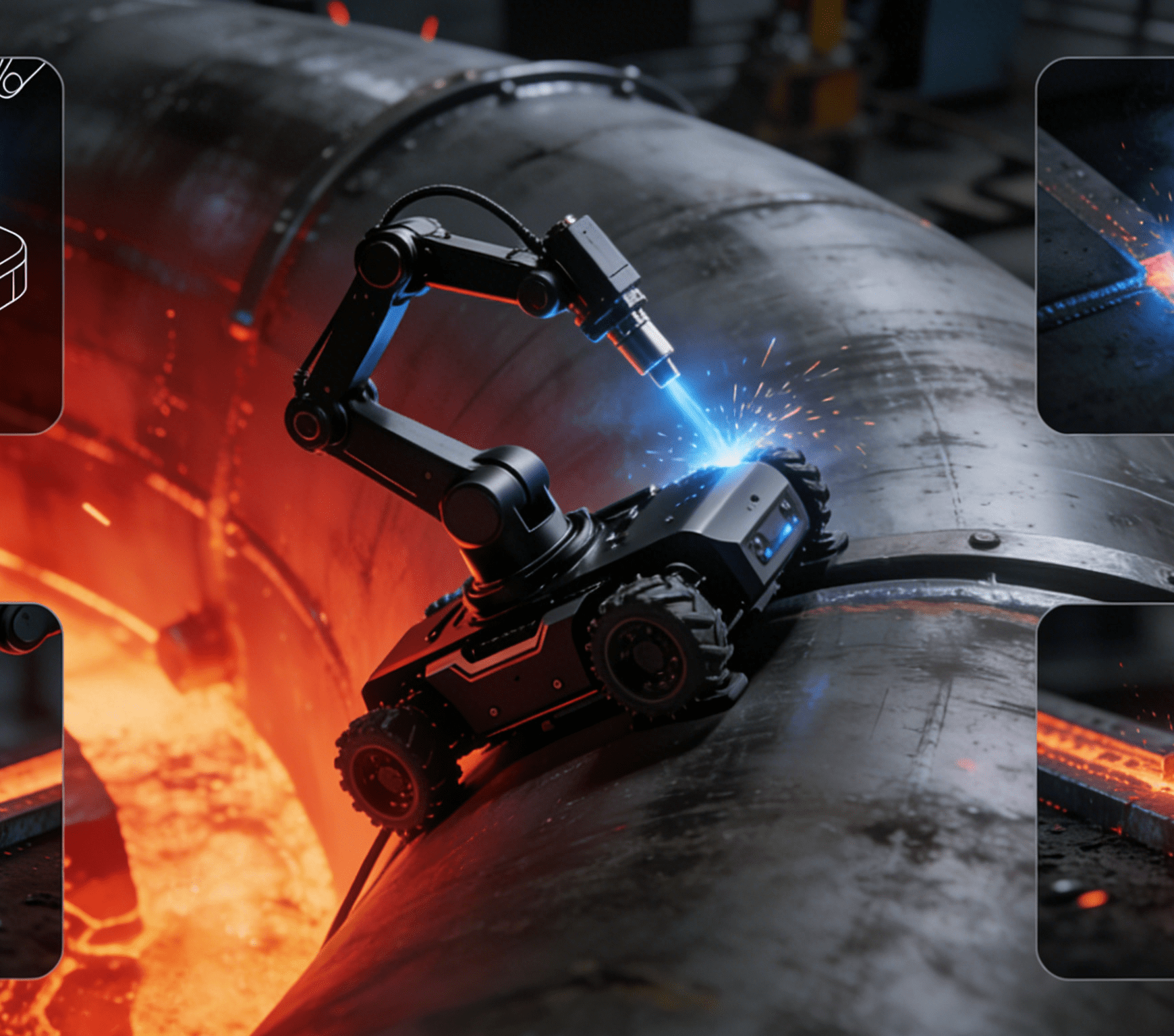

Aerospace:Machining of complex components such as turbine blades and engine parts, which require high precision and intricate surface geometries.

Automotive Manufacturing:High-volume production of high-precision parts such as engine components and gearbox housings.

Medical Devices:Production of high-precision, consistent components and surgical instruments where accuracy is critical. Notably, it plays a key role in manufacturing core parts for Машина за сглобяване на катетриs—such as precision guide rails, rotating clamping mechanisms, and microfluidic channel components—by leveraging its single-clamping multi-angle machining capability to achieve micron-level precision in tapered, curved, and grooved structures, ensuring the assembly accuracy and biocompatibility of medical catheters.

Electronics:Machining of small, precision parts such as mobile phone casings and precision connectors.

Conclusion

By adding a rotary axis, 4-axis CNC machining technology significantly enhances the machining capability and flexibility of CNC machining centers. It not only improves production efficiency while maintaining high precision, but also expands the scope of machinable parts. In modern manufacturing, 4-axis CNC machining has become an essential tool for processing complex components and boosting production efficiency. Ares Precision should select the appropriate CNC machining process based on specific machining requirements and part complexity to achieve optimal machining results. The widespread application of 4-axis CNC machining across various industries fully demonstrates its importance and promising prospects in modern manufacturing.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine