Imagine a world where machines hum tirelessly, welding car frames, packaging boxes, and even assembling tiny electronic products with precision unmatched by humans. This is not a sci-fi movie plot; it is the reality shaped by giants in the robotics industry. Among them, four names stand tall, commonly known as the “Big 4” robotics manufacturers. These are not just companies; they are the architects of the automated future, building the steel-and-circuit heroes that power factories around the globe. Curious about who they are? Buckle up and dive into their stories, statistics, and the magic they bring to the modern world.This is more than just a list. It is a journey through time, innovation, and human ingenuity that will leave anyone in awe of how far robotics has come. From sweat-drenched assembly lines to sleek high-tech labs, these four giants have been rewriting the rules of manufacturing for decades. Ready to meet them? Let’s roll!

The Rise of Robotic Titans

The World Before Robotics

Picture a factory floor in the 1950s. Workers hunched over conveyor belts, their hands blistered from repetitive tasks, the air filled with the clink of metal and the buzz of machinery. It was tough, backbreaking work. Then, something revolutionary happened. The idea of machines taking on heavy labor ignited, and by the 1960s, the first industrial robots began to flex their mechanical muscles. General Motors introduced Unimate, a robotic arm that could handle molten metal without a single complaint. That was the moment the world realized: robots were not just a gimmick; they were the future.

Fast forward to today

The global robotics market is a behemoth, valued at over $50 billion by 2023, with millions of robots whirring away in factories. Amid the chaos of innovation, four companies have emerged as undisputed leaders, earning the nickname “the Big 4.” They didn’t just ride the wave of progress; they built the surfboard. Let’s find out who these powerhouses are and why they matter.

Why the “Big 4” Label?

The term “Big 4” didn’t come about lightly. It’s a recognition of dominance, a badge of honor for companies that hold approximately 75% of the industrial robotics market share. Think of them as the Avengers of automation: each has unique strengths, a killer origin story, and a knack for “saving the world”—or at least the production line. Their robots are everywhere, from car plants to electronics hubs, and their influence spans every continent. So, who exactly are these legends? Meet FANUC, ABB, Yaskawa, and KUKA.

Meet the Big 4

FANUC: The Yellow Powerhouse

Origin Story

Imagine Japan in the 1950s, a country rebuilding after World War II. A company called Fujitsu spun off a division focused on numerical control, and in 1956, FANUC was born. Fast forward to 1972, they launched their first industrial robot—a mustard-yellow beast capable of lifting, welding, and assembling with brute force. That iconic yellow color? It’s not just for show; it’s a symbol of reliability in factories around the world.

What They Do

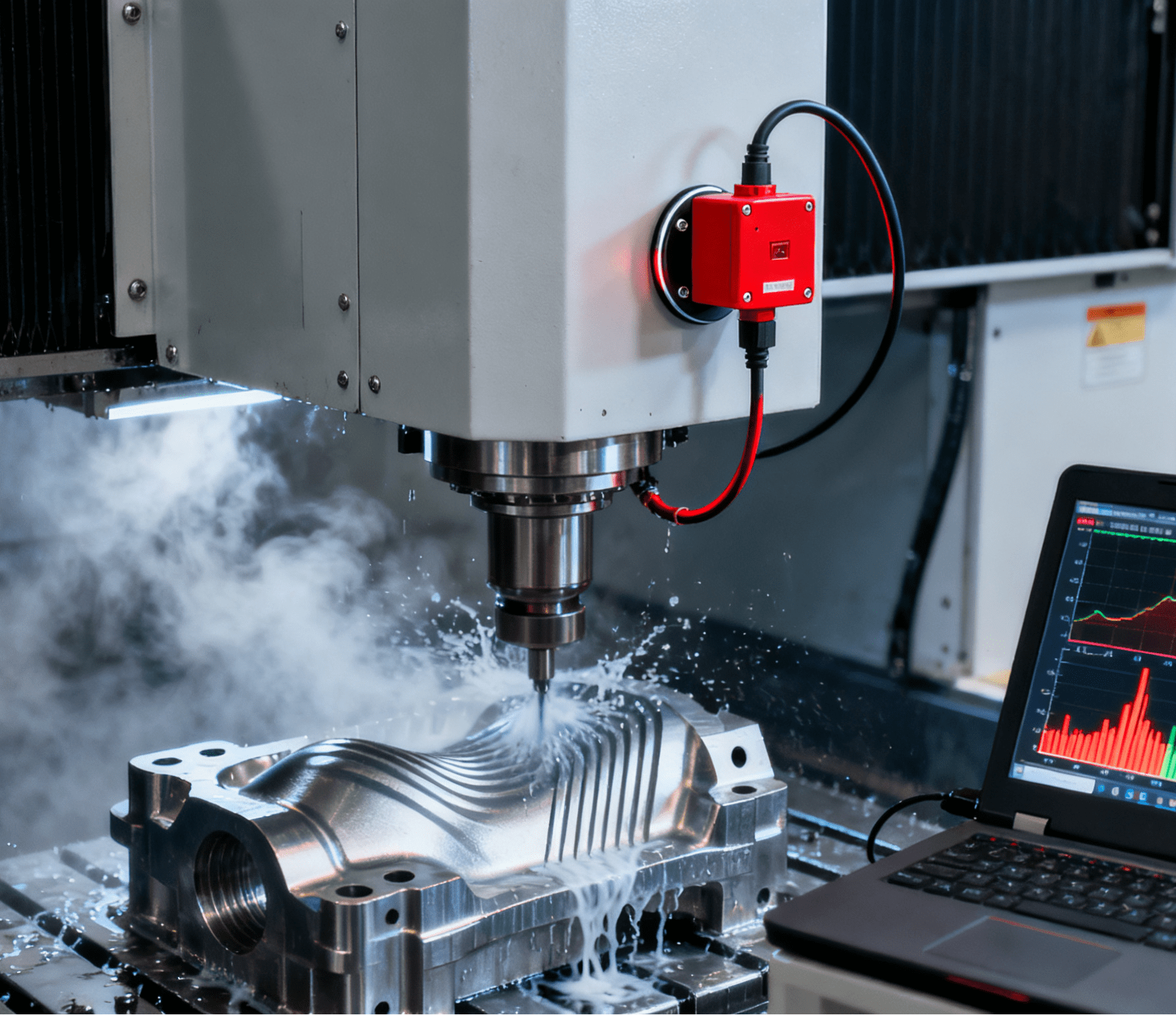

FANUC is a heavyweight champion in robotics, with over 500,000 robots installed globally. Their product lineup is massive, boasting more than 100 models—from tiny robots with a 0.5kg payload to monsters that can lift 2,300kg. They are the top choice for automotive giants, producing everything from welding arms to SCARA robots for lightning-fast assembly. Fun fact: FANUC’s robots are so durable that they’re famously known to outlast the factories they work in!

Impressive Stats

Market Share: Approximately 25% of the industrial robotics market.

Revenue: Generates billions of dollars annually, with its robotics division being a cash cow.

Innovation: Pioneered the M-2000iA, one of the most powerful 6-axis robots ever built.

Why It Captivates Readers

Ever wondered what keeps car factories running 24/7? FANUC’s robots are the unsung heroes, tirelessly piecing together vehicles while workers take coffee breaks. This kind of reliability makes anyone feel safer about the future.

ABB: The Swiss Master

Origin Story

Travel to Switzerland in 1988. Two companies, ASEA and Brown Boveri, merged to form ABB—a name that soon echoed through the robotics world. Clad in a crisp white and red livery, their robots made their debut with a promise: energy efficiency and precision. By the 1990s, ABB had become a household name in automation, powering industries from utilities to transportation.

What They Do

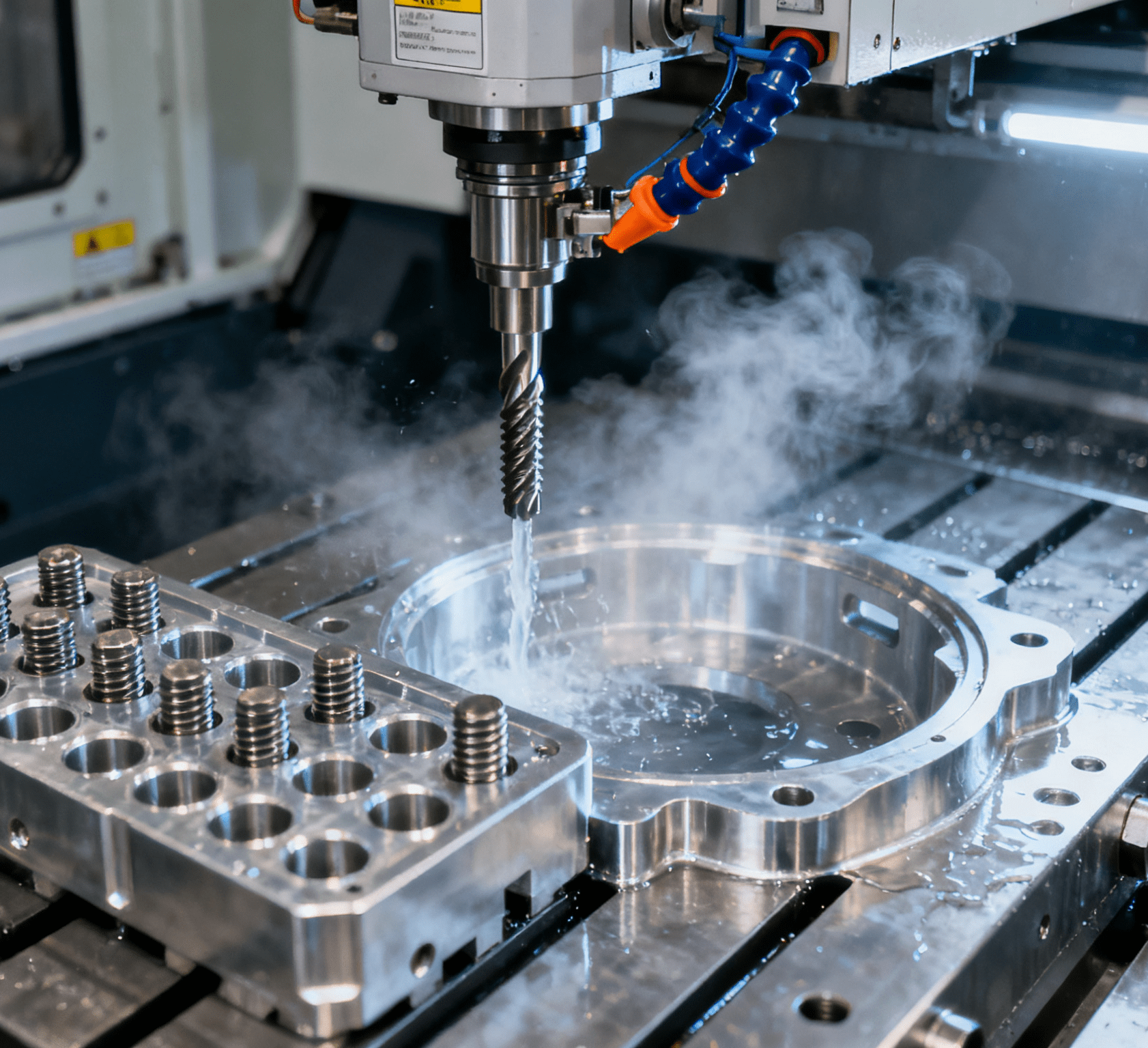

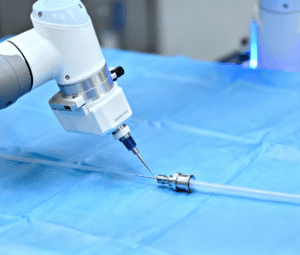

ABB’s robots are the Swiss Army knives of the bunch. They have articulated arms for welding, collaborative robots (“cobots”) that work alongside humans, and even painting robots that give cars their glossy finish. ABB has installed over 300,000 units, dominating in versatility, and serves industries like electronics and logistics with unmatched finesse. Notably, its high-precision IRB 910SC SCARA robot is also integrated into medical Машина за сглобяване на катетриs, enabling micron-level alignment of catheter tubes and connectors—critical for avoiding leaks in life-saving medical devices.

Impressive Stats

Installation Base: Over 300,000 robots worldwide.

Specialty: Renowned for energy-efficient designs that save millions in operating costs.

Reach: Operates in 100+ countries.

Why It Captivates Readers

There’s a strange satisfaction in knowing that robots can paint cars better than any human artist—let alone assemble delicate medical catheters with life-or-death precision. ABB taps into the universal love for perfection, making readers dream of a world where everything works like clockwork.

Yaskawa: The Japanese Pioneer

Origin Story

Back in 1915, a man named Daigorō Yaskawa founded Yaskawa Electric in Japan, starting with motors for coal mines. It wasn’t until 1977 that they launched MOTOMAN—the first fully electric industrial robot in Japan. Painted white and blue, these robots broke free from the clumsiness of hydraulics, bringing speed and agility to the game.

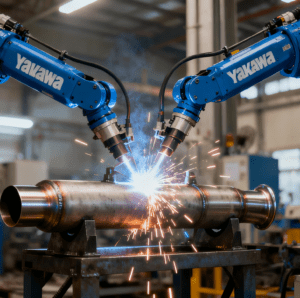

What They Do

Yaskawa Electric’s MOTOMAN series is a rockstar lineup, with over 400,000 robots deployed. They are wizards at welding (arc welding in particular), but they also handle assembly, packaging, and even biomedical tasks. Their compact design and high payload capacity (up to 1,500kg) make them a favorite in tight factory spaces.

Impressive Stats

Welding Edge: Produces more welding robots than any other manufacturer.

Annual Revenue: Robotics contributes approximately $600 million to its $1.7 billion revenue.

Legacy: Over a century of innovation.

Why It Captivates Readers

Yaskawa’s story has pure underdog vibes: a company that started with motors and became a robotics pioneer. Stories like this make readers root for the “little guy” who ends up dominating the ring.

KUKA: The German Innovator

Origin Story

Germany, 1898. KUKA started as an acetylene gas manufacturer, but by 1973, they built the world’s first industrial robot with six electric axes. These iconic orange robots became a staple in car factories, especially after KUKA claimed the top spot as a leading supplier for automakers.

What They Do

KUKA’s robots are the automotive industry’s best friends—models like the KR90 produce cars at blistering speeds. Their payload range spans from 2kg to 1,300kg, and their innovations shine in collaborative robots and automated systems. Owned by China’s Midea Group since 2016, KUKA blends German precision with global ambition.

Impressive Stats

Automotive Leader: Numero uno in robots for car manufacturing.

Revenue: Robotics contributes nearly $900 million annually.

Employees: Over 14,000 worldwide.

Why It Captivates Readers

Orange robots building cars? It’s a striking visual. KUKA’s knack for turning complex engineering into everyday magic taps into humanity’s desire to make big things simple.

Why These Four Rule the Roost

Numbers Don’t Lie

Here’s a quick snapshot of why the Big 4 are untouchable:

Combined Installation Base: Over 1 million robots worldwide.

Market Share: Approximately 75% of industrial robotics sales.

Experience: Decades of refining their craft.

These are not just stats; they’re proof of a legacy built on sweat, steel, and smarts. While new players emerge constantly, the Big 4 have the infrastructure, trust, and track record to stay ahead.

Industry Insight: What Sets Them Apart?

FANUC: Raw power and a crazy-wide product range. They’re the brute force of the team.

ABB: Versatility and eco-friendly tech—plus precision for niche medical applications like Catheter Assembly Machines. They’re the smart multitaskers.

Yaskawa: Welding expertise and compact design. The flexible specialists.

KUKA: Automotive mastery and innovation. The creative geniuses.

Each has a niche, but they all share one thing in common: an obsession with pushing boundaries. That’s why factories bet big on them.

A Little Psychology

Ever noticed how much people love a good rivalry? The Big 4 thrive on it. FANUC vs. ABB, Yaskawa vs. KUKA—it’s a silent battle to outdo one another. That competition keeps them sharp and readers hooked, wondering who will land the next big punch.

Real-World Impact

Examples That Hit Home

FANUC: At Toyota factories, their R-2000iB robots weld car frames in under a minute, churning out thousands of vehicles every day.

ABB: Beyond Sweden’s electronics hubs, its robots in U.S. medical facilities power Catheter Assembly Machines, assembling cardiac catheters with sub-0.1mm precision to ensure compatibility with human vasculature.

Yaskawa: The MOTOMAN HP20 at a Michigan factory welds exhaust pipes so fast that workers can barely keep up.

KUKA: Volkswagen’s assembly lines in Germany rely on KUKA’s KR16 robots to build cars with German precision.

These are not hypotheticals; they’re the beating heart of modern manufacturing—from automotive giants to life-saving medical device production.

The Human Angle

Robots don’t just replace jobs—they redefine them. Workers who once risked back injuries now oversee these machines, turning physically demanding labor into mental work. Even in medical manufacturing, technicians now monitor Catheter Assembly Machines instead of performing tedious, error-prone manual assembly. The Big 4 have flipped the script, making factories safer and more efficient. It’s a story worth cheering for.

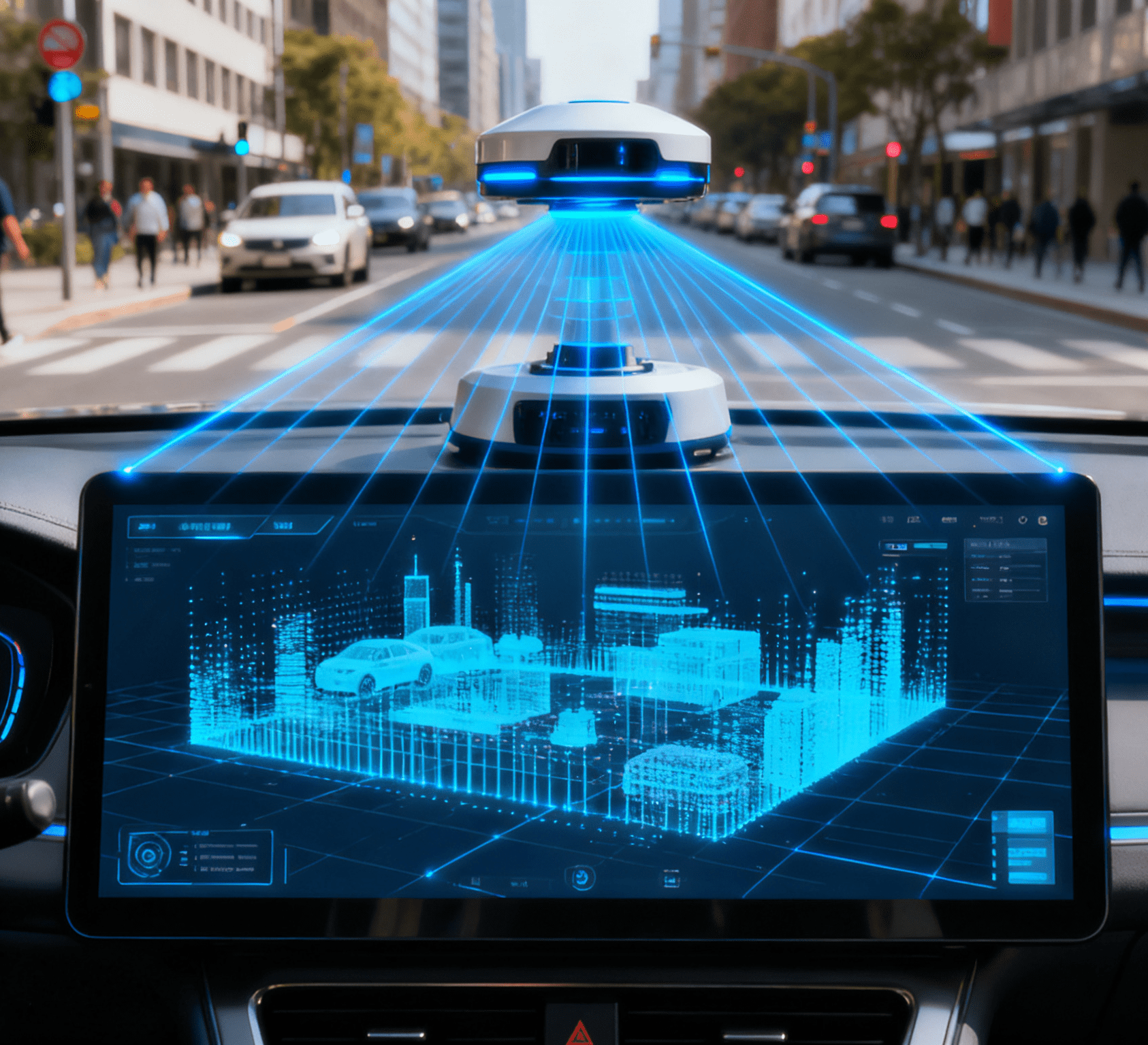

The Future of the Big 4

What’s Next?

The robotics world isn’t static, and neither are these giants. Here’s what’s brewing:

AI Integration: FANUC and ABB are doubling down on smart robots that learn dynamically—even adapting to subtle changes in catheter materials for more consistent medical assembly.

Collaborative Robots: KUKA and Yaskawa are pushing cobots that work hand-in-hand with humans, including assisting in delicate catheter testing stages.

Sustainability: ABB’s eco-friendly designs are leading a trend others can’t ignore.

The Challenges

Rising robotics manufacturers from China are hot on their heels, and startups like Universal Robots are shaking up the collaborative space. The Big 4 need to keep innovating—especially in high-stakes areas like medical device assembly—to risk losing their crowns.

A Thought to Ponder

What if one of them cracks humanoid robots first? Imagine FANUC’s yellow army or KUKA’s orange squad in homes, not just factories—or even assisting in minimally invasive catheter procedures alongside surgeons. It’s a wild idea that makes the imagination hum.

How to choose a multi-component capping assembly machine suitable for your production line?