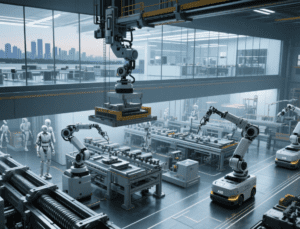

As a key industrial project in Zhejiang Province, the headquarters of Xinjian Transmission will build an intelligent base integrating R&D, production and testing, focusing on the layout of humanoid robot joint drive systems and high-precision planetary roller screw production lines for automobiles. The accumulation of such precision manufacturing technologies will also provide technical support for the upgrading of industrial equipment such as damper assembly machines — through the integration of high-precision transmission components and intelligent control systems, automated precision assembly of multiple components such as damper valve cores and sealing rings can be realized.

- Construction site: “Summer symphony” of tackling key projects in midsummer

In the sweltering heat of Qingshanhu Science and Technology City in midsummer, the construction site of the Xinjian Transmission headquarters project located on the north side of Science and Technology Avenue is in a bustling scene. More than 200 constructors are working intensively on various factory floors. The knocking sound of wall masonry and the clanging of frame cleaning interweave into a “summer symphony” of project. Since the project started on January 3, 2025, it has entered a critical stage where the main structure and decoration are advancing simultaneously, and it is expected to complete all construction tasks by the end of the year.

- Construction of multi-storey factory building: Indoor operations proceed in an orderly manner

In the 4-storey multi-storey factory building, the masonry team at the southwest corner of the second floor is carrying out internal partition wall construction. Several workers cooperate tacitly: some push small mixers to transport special lightweight blocks, some hold laser locators to calibrate the wall axis… all working in full swing. At the same time, the 9-storey high-rise factory building has been built to the 8th floor structure and will be fully capped by mid-August. On the top floor working surface, more than 10 workers are finishing the concrete pouring, and tower cranes accurately lift building materials to designated positions. “At present, the construction progress of the high-rise main structure is a few days ahead of schedule, and the exterior decoration is being finished,” said Jin Jianfeng, project manager of Zhejiang Shouchuang Construction Engineering Co., Ltd., the construction unit, pointing to the construction schedule.

- Project scale: Layout of an intelligent base with over 70,000 square meters

The total land area of the project is 26,561 square meters, with a total construction area of 70,952.89 square meters, consisting of Building 1, Building 2 and a basement. Among them, Building 1 is the core production area, including a 9-storey high-rise factory building and a 4-storey multi-storey factory building, with a partial basement used as equipment rooms.

- Response to high temperature: Both “avoiding peak construction + safeguard measures” are ensured

Faced with the recent high temperature weather, the project department has launched a combination of “avoiding high temperature and ensuring progress”: outdoor operations are suspended from 10:30 to 14:00 every day, and concentrated construction is carried out in the morning and evening; cooling spots are set up on site, equipped with Huoxiang Zhengqi liquid and other heatstroke prevention items. “We start work at 5:30 in the morning, finish the exterior wall work before 10 o’clock, and switch to indoor hardcover in the afternoon,” said Master Wang, a painter, wiping his sweat.

- Quality control: Double guarantee of progress and precision

“We must not only rush for progress but also ensure precision,” introduced Jin Jianfeng, the project manager. When each construction section is completed, the masonry team and the cleaning team must jointly inspect and sign to ensure that “wall flatness meets the standard” and “site clearance rate of 100%” are achieved simultaneously. Overlooking from a height, this smart factory, which will carry the core components of humanoid robots in the future, is growing rapidly at a speed of “building half a layer of walls a day and clearing thousands of materials a day”.

- Project positioning: Capacity planning of the largest core component base in the Yangtze River Delta

As a key industrial project in Zhejiang Province, the headquarters of Xinjian Transmission will build an intelligent base integrating R&D, production and testing, focusing on the layout of humanoid robot joint drive systems and high-precision planetary roller screw production lines for automobiles. The project adopts the “industry going upstairs” model, realizing seamless connection of production processes through vertical space optimization. After putting into production, the annual capacity can reach 1 million units, and it is expected to become the largest production base of humanoid robot core components in the Yangtze River Delta region.

Automatic assembly machine for switch components

AI automatic assembly robot for switch components