In the field of high-end manufacturing, precision machining serves as a crucial link in transforming blueprints into high-precision physical components. Ranging from complex structural parts in aerospace to micro-components in medical devices, CNC (Computer Numerical Control) precision machining technology, with its millimeter-level accuracy control and intelligent processes, provides reliable foundational support for modern industry. This article analyzes how precision machining empowers the upgrading of high-end manufacturing from the perspectives of technical principles, application scenarios, and process advantages.

The Technical Core of Precision Machining: Evolution from Traditional to Intelligent

Centered on “precision”, precision machining achieves accurate control of the machining process through CNC systems. Its core technologies include:

Multi-Axis MachiningBy leveraging 3-axis, 4-axis, and up to 5-axis machining technologies, it enables one-time forming of parts with complex curved surfaces, eliminating precision errors caused by multiple process transfers in traditional machining.

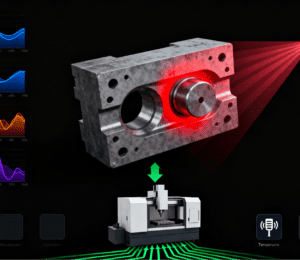

Intelligent Compensation TechnologyAiming at dynamic errors such as machine tool thermal deformation and tool wear, it collects real-time data through sensors, imports the data into algorithm models, and automatically adjusts machining parameters. This controls dimensional accuracy at the micrometer (μm) level, meeting the strict requirements for implant components in medical devices.

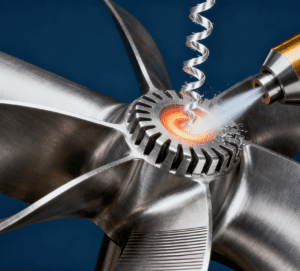

Material-Adapted ProcessesFor difficult-to-machine materials such as titanium alloys, superalloys, and carbon fiber composites, specialized tool paths and cooling solutions are developed. For example, when machining titanium alloy blades of aero-engines, high-pressure internal cooling technology is used to reduce cutting heat and prevent thermal stress deformation of the material.

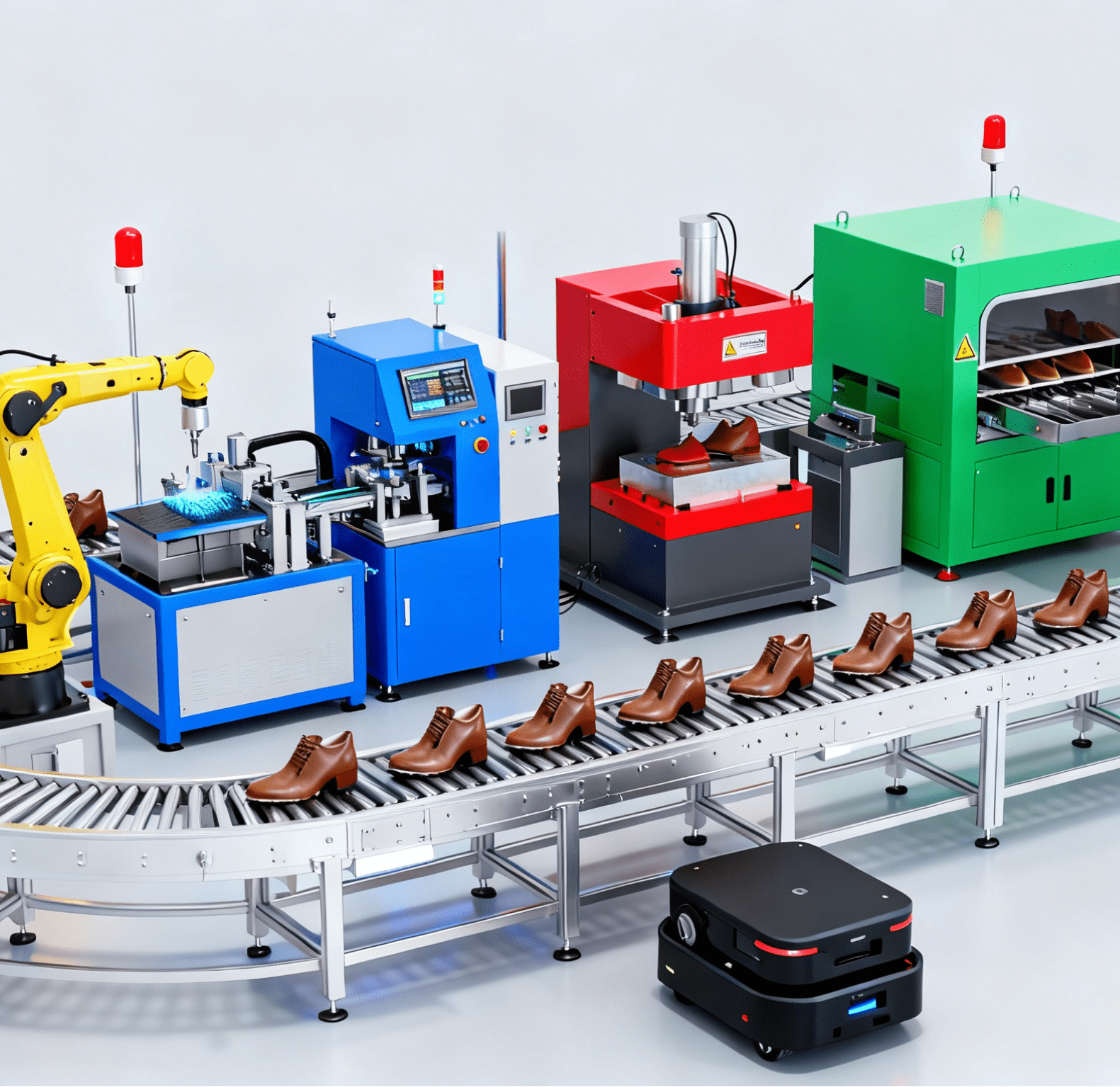

Automated Loading and Unloading IntegrationAs an important part of intelligent machining lines, sheet automatic loading robots have become a key support for improving processing efficiency and consistency. Equipped with high-precision visual positioning and adaptive clamping mechanisms, these robots can automatically complete the grabbing, positioning, and loading of metal or composite sheets of different thicknesses and sizes into CNC machine tools. They avoid precision deviations caused by manual lifting and positioning, and realize seamless connection with subsequent machining processes. For batch processing scenarios such as automotive precision parts or electronic device shells, sheet automatic loading robots can reduce manual intervention by more than 80% and shorten the single-piece processing cycle by 15%-20%, while ensuring the uniformity of blank positioning accuracy within ±0.03mm.

Diverse Application Scenarios: The Industrial Footprint of Precision Components

Aerospace: The Ultimate Pursuit of Reliability FirstLanding gear structural parts: CNC precision machining enables the lightweight design of high-strength aluminum alloy materials, reducing the overall weight of the aircraft while ensuring load-bearing capacity.Micro-components for avionics systems: Components such as connector pins require concentricity accuracy at the 0.001mm level to ensure stable signal transmission.

Medical Devices: Dual Standards of Safety and PrecisionOrthopedic implants: The surface roughness of artificial joint prostheses must be controlled below Ra0.2. Precision grinding processes are used to achieve bionic design, reducing the body’s rejection response.Medical imaging equipment: The rotating frame components of CT scanners need to meet a positioning accuracy of 0.01° to ensure the clarity of tomographic images.

Electronic Communication: Technical Challenges of Miniaturization and Integration5G base station filters: The dimensional tolerance of aluminum alloy cavity parts must be controlled within ±0.02mm, and high-speed CNC milling is used to achieve precision machining of micro-hole systems.Consumer electronics structural parts: The stainless steel brackets of mobile phone camera modules require precision turning-milling composite machining to achieve 0.1mm-level thin-walled structure forming, meeting the design needs of ultra-thin phone bodies.

The Manufacturing Philosophy Behind Precision

The essence of precision machining lies in transforming “millimeter-level” precision requirements into mass-producible industrial standards through technological innovation. From the “national heavyweight equipment” in aerospace to the “essential civilian products” in medical devices, every precision component is the result of in-depth integration of materials science, CNC technology, and quality control. For high-end manufacturing enterprises, choosing a partner with full-process precision machining capabilities is not only about obtaining qualified parts but also about laying a solid technical foundation for product performance and reliability.