In modern manufacturing, precision CNC (Computer Numerical Control) machining undoubtedly occupies an extremely important position. Leveraging its advantages of high precision, high efficiency, and repeatability, CNC machining can accurately produce parts and components of various complex shapes, and is widely applied in numerous high-end fields such as aerospace, automobile manufacturing, and medical equipment. This inevitably leads people to wonder: amid the tide of the precision CNC machining era, has traditional craftsmanship been completely eliminated?

CNC Machining’s Dominance: Unmatched Precision and Efficiency

By controlling machine tool movements through computer programs, precision CNC machining can achieve machining precision at the micrometer or even nanometer level. It excels at rapid mass production with stable, reliable quality—for instance, in manufacturing aircraft engine blades, it precisely shapes complex curved surfaces and internal cooling channels, ensuring performance under extreme conditions. These strengths solidify CNC machining’s core role in high-end manufacturing, yet they do not render traditional craftsmanship obsolete.

The Irreplaceable Value of Traditional Craftsmanship

Traditional craftsmanship holds profound historical heritage and unique value in precision processing:

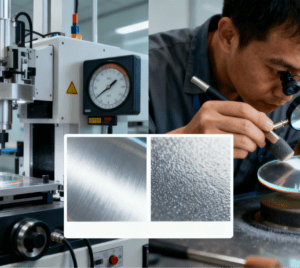

Ultra-fine Finishing: Skilled craftsmen use keen tactile sense and exquisite skills for precision trimming and polishing—critical for optical lenses requiring near-perfect flatness, where manual grinding removes micro-defects that CNC machining struggles to replicate.

Special Material Processing: For high-strength alloys or super-hard materials, craftsmen’s flexible control of angles and forces overcomes CNC challenges like rapid tool wear.

Mold & Special Fields: CNC handles rough/semi-finishing for molds, but manual refinement of parting surfaces and fillets ensures clamping precision and reduces defects. In artistic creation and cultural relic restoration, craftsmanship endows works with unique vitality and historical charm.

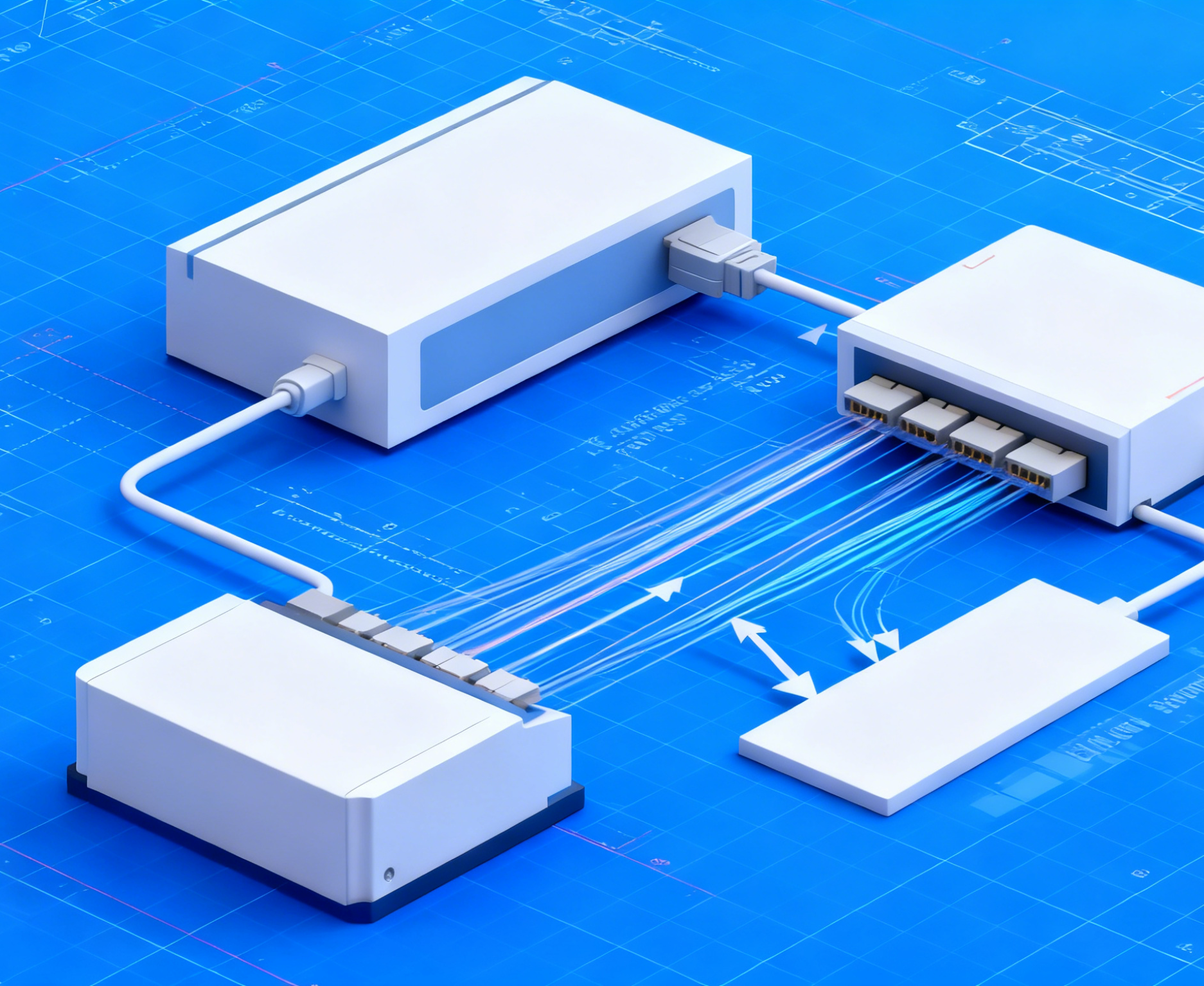

Precision Calibration for Automated Equipment: Even in the operation of automatic placement machines—core equipment in electronic manufacturing that relies on CNC-machined high-precision linear guides and positioning platforms to achieve micron-level component placement—traditional craftsmanship plays an irreplaceable role. When dealing with ultra-small, irregularly shaped electronic components or calibrating tiny positional deviations that exceed the machine’s automatic compensation range, skilled craftsmen rely on their accumulated experience and sensitive tactile feedback to perform manual fine-tuning. This not only compensates for minor machining tolerances of the placement machine’s core components but also ensures the stability and accuracy of component mounting in high-density circuit board production—an effect that purely automated algorithms and mechanical systems struggle to achieve.

Complementary Synergy: Craftsmanship as a Foundation for CNC Development

The two are not opposites but complementary: Traditional craftsmanship serves as a vital foundation for cultivating CNC talents. Learning manual processing deepens understanding of material properties, process principles, and tool-workpiece interactions—knowledge that optimizes CNC programming and solves on-site problems.

In conclusion, although precision CNC machining shines brilliantly in modern manufacturing, traditional craftsmanship has not been completely eliminated. The two are not mutually opposed but complement each other. While pursuing high precision and high efficiency, we must not ignore the human wisdom and unique value embodied in traditional craftsmanship. Only by organically combining precision CNC machining with traditional craftsmanship can we go further on the path of manufacturing development, create more high-quality and high-performance products, promote the continuous progress of the entire industry, allow traditional craftsmanship to be inherited and carried forward in the wave of modern technology, and jointly contribute to the progress of humanity and the development of civilization.