Eyeshadow cases feature diverse designs with varying sizes, compartment structures, and material combinations, posing great challenges to efficient assembly in cosmetic production. Traditional manual operations or semi-automatic equipment struggle with frequent batch changes, low efficiency, and unstable quality. The full-automatic eyeshadow case assembly machine effectively addresses these pain points, becoming a core equipment for upgrading cosmetic packaging lines.

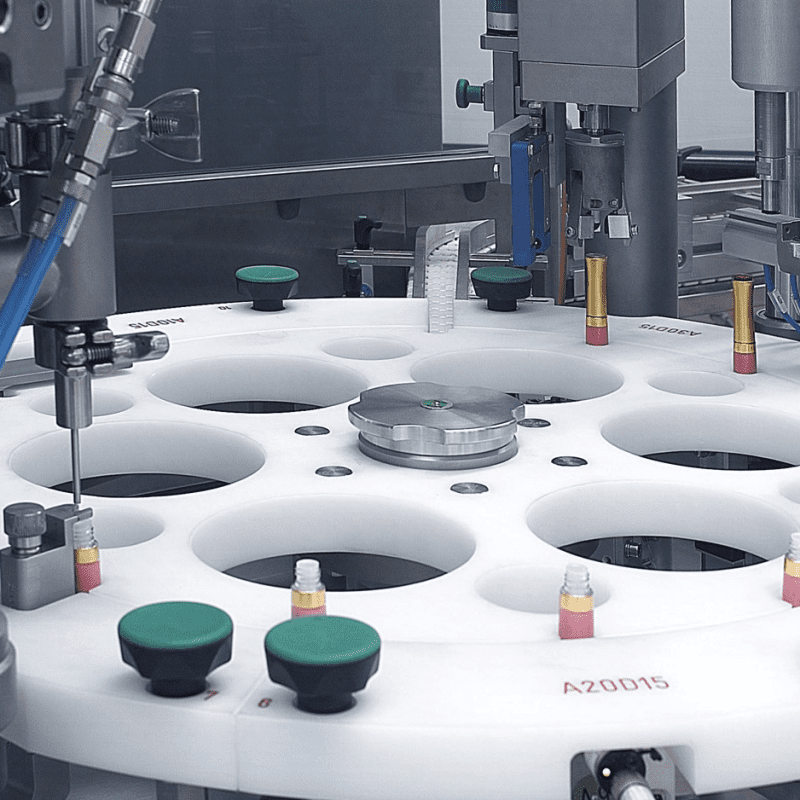

Compatible with Multiple Case Specifications

To cope with the diversity of eyeshadow cases, the machine is equipped with a modular quick-change system. It supports flexible switching between plastic, metal, and composite material cases, as well as single-compartment, multi-compartment, and hinge-type structures. The optimized fixture design allows operators to complete parameter adjustment and fixture replacement within 5 minutes, reducing batch change downtime by over 65% compared to traditional equipment, and perfectly matching small-batch customization and large-scale mass production needs.

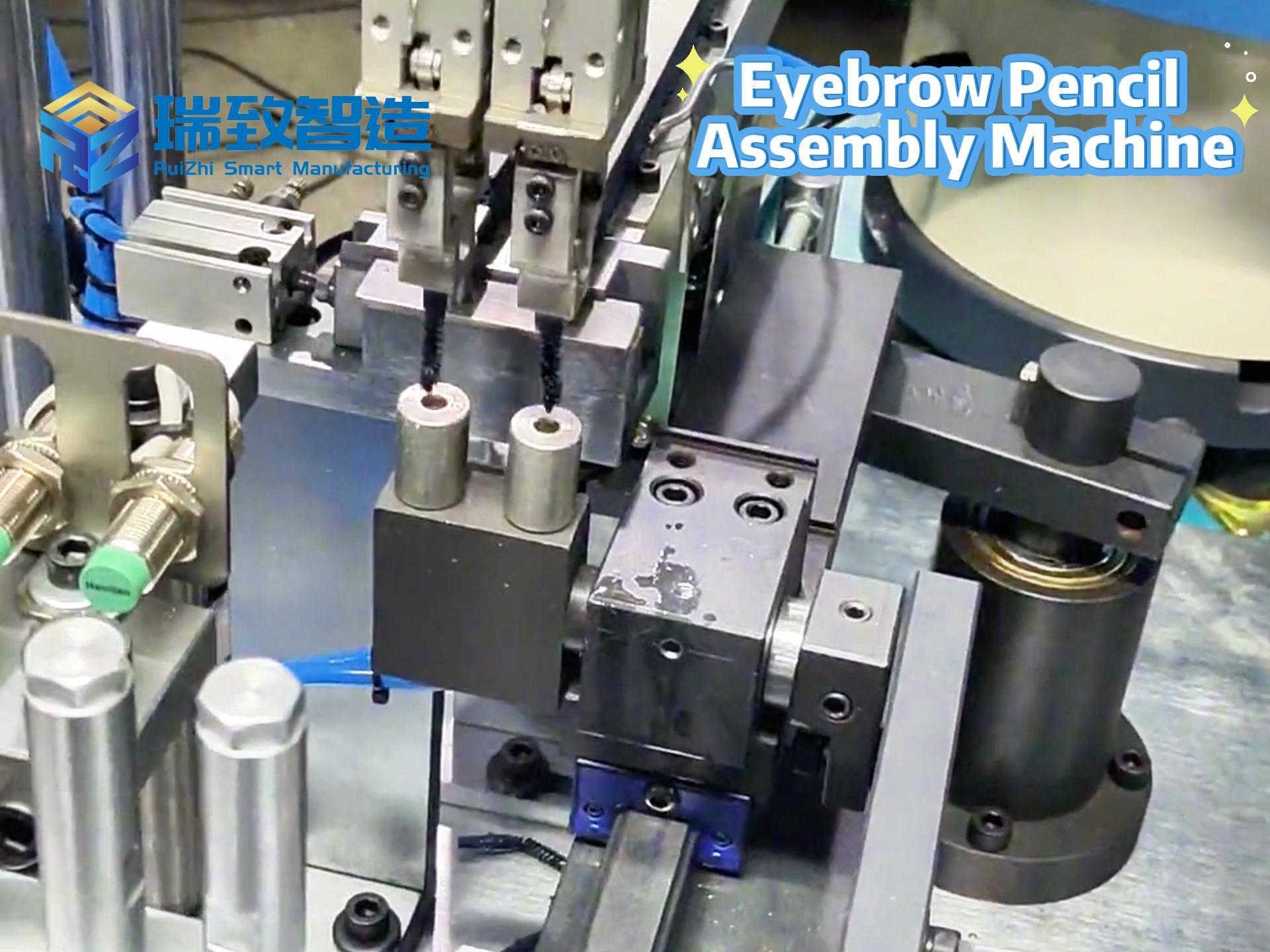

Balance Efficiency and Quality

Integrated with visual recognition and PLC intelligent control, the machine achieves full-process automation from feeding, positioning, bonding to hinge installation. Built-in pressure detection and appearance inspection modules real-time monitor assembly accuracy, effectively avoiding defects like misaligned compartments, loose hinges, and uneven gluing, with a defect rate controlled below 0.5%. It can reach a maximum speed of 3600 pieces per hour, replacing 6-8 manual workers and improving overall production efficiency by over 30%.

Easy to Clean and Maintain

Adhering to FDA and GMP cosmetic production standards, all parts in contact with the eyeshadow case are made of food-grade 316L stainless steel, ensuring production safety. The machine adopts a detachable structure, with smooth surfaces that avoid dust accumulation and facilitate daily cleaning and disinfection, preventing cross-contamination. Additionally, its simplified maintenance design reduces daily upkeep difficulty, and the fault alarm system promptly reminds operators of issues, minimizing production interruption.

This full-automatic assembly machine solves key problems in eyeshadow case production with flexible adaptation, intelligent quality control, and compliant design, providing reliable support for cosmetic enterprises to achieve efficient, stable, and standardized packaging production.

Assembly line for mass production by artificial intelligence