Against the backdrop of the accelerated evolution of the manufacturing industry, computer numerical control (CNC) intelligent machining, as a core link of precision manufacturing, is undergoing a profound transformation from traditional models to smart manufacturing. Driven by digital transformation, key technologies such as the Internet of Things (IoT) and Digital Twin have become pivotal driving forces, helping enterprises break down equipment silos and achieve efficient interconnection and real-time monitoring. Traditional intelligent machining is often limited by manual operations and low process visibility, while the intelligent transformation improves overall efficiency through data integration, laying a solid foundation for subsequent production optimization.

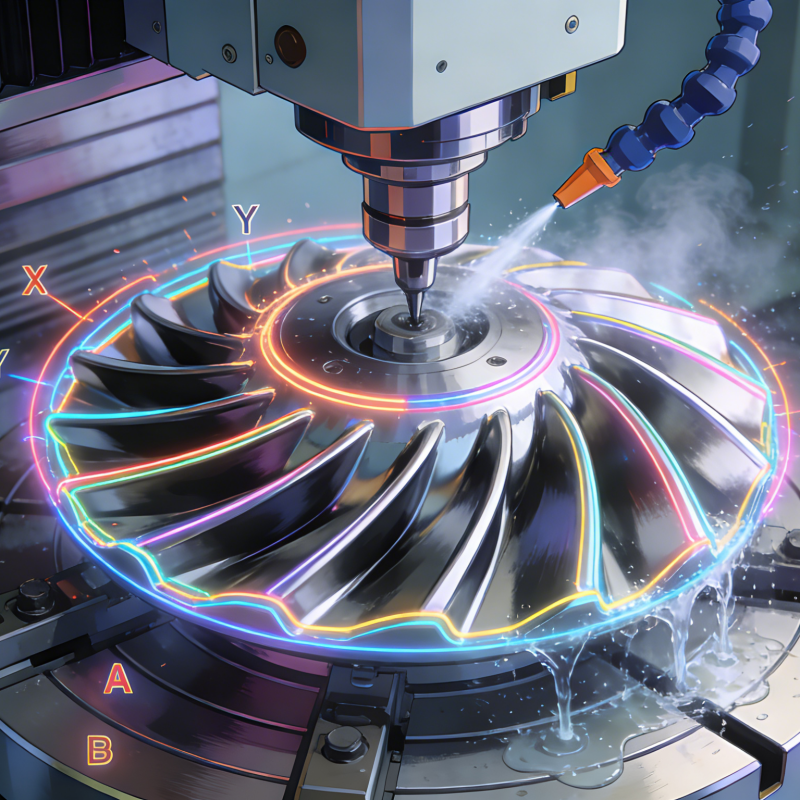

Digital Twin Visualization

Digital Twin technology provides core support for the visualization process in the field of intelligent machining. By constructing an accurate digital mapping of physical equipment, production lines and even entire workshops in a virtual space, it achieves an unprecedented level of transparency in the manufacturing process. Real-world data collected in real time by sensors—such as equipment status, tool wear, workpiece position, temperature and vibration parameters—continuously drives the update of the Digital Twin model. This enables managers to intuitively monitor the dynamic operation of the entire intelligent machining process, as if they were on-site in person. Furthermore, this high-fidelity visualization is not only limited to real-time status display; more importantly, it provides a solid foundation for simulation, prediction and optimization. For example, operators can pre-verify the machining programs of complex parts in a virtual environment or simulate the effects of different production scheduling strategies, thereby identifying potential problems and optimizing decisions before physical implementation, effectively shortening debugging time and reducing trial-and-error costs. In the practice of precision manufacturing enterprises, visualization platforms based on Digital Twin have become a key technical means to improve the precision of process control and response speed.

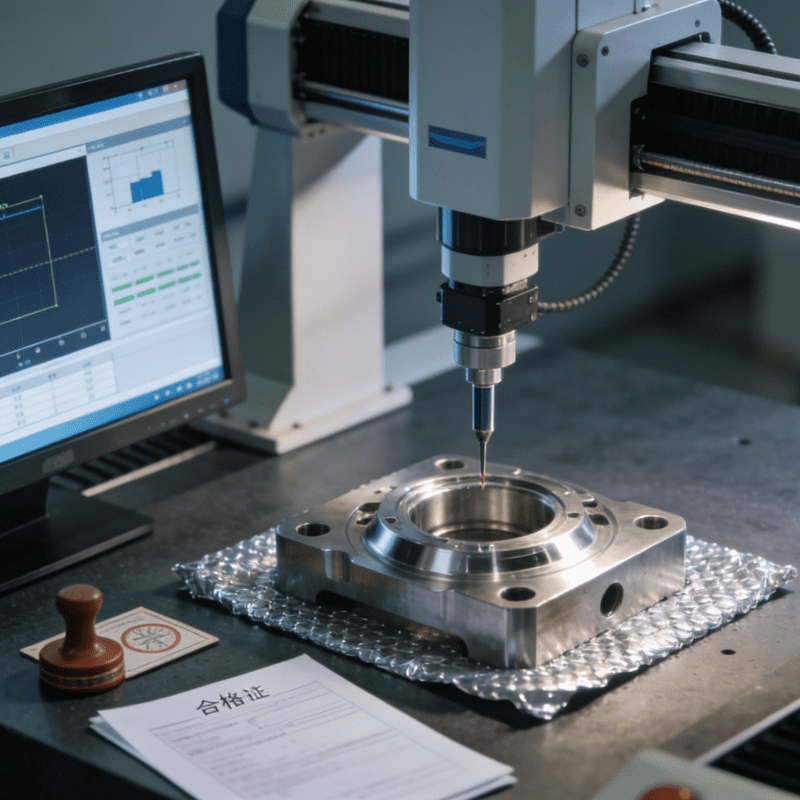

AI-driven Intelligent Quality Control

Following the realization of production process visualization, AI-driven intelligent quality control has become a critical link to ensure the precision of intelligent machining. Through computer vision technology and machine learning algorithms, intelligent inspection systems are capable of capturing and comparing real-time images of finished machined components in milliseconds. Compared with traditional manual random inspection or contact measurement, this non-contact inspection method is not only faster, but also achieves 100% full inspection coverage, significantly reducing the risk of missed defects. The built-in deep learning model of the system can actively identify subtle trends of quality fluctuations and even predict the occurrence of potential defects by continuously analyzing massive machining data. For instance, after a leading home appliance enterprise deployed such a system on its precision mold intelligent production line, the qualification rate of key dimensions rose to over 98%, while the labor cost of the quality inspection process was reduced by nearly 40%. At the same time, real-time generated quality analysis reports are directly fed back to the production control system, providing data support for the immediate optimization of process parameters.

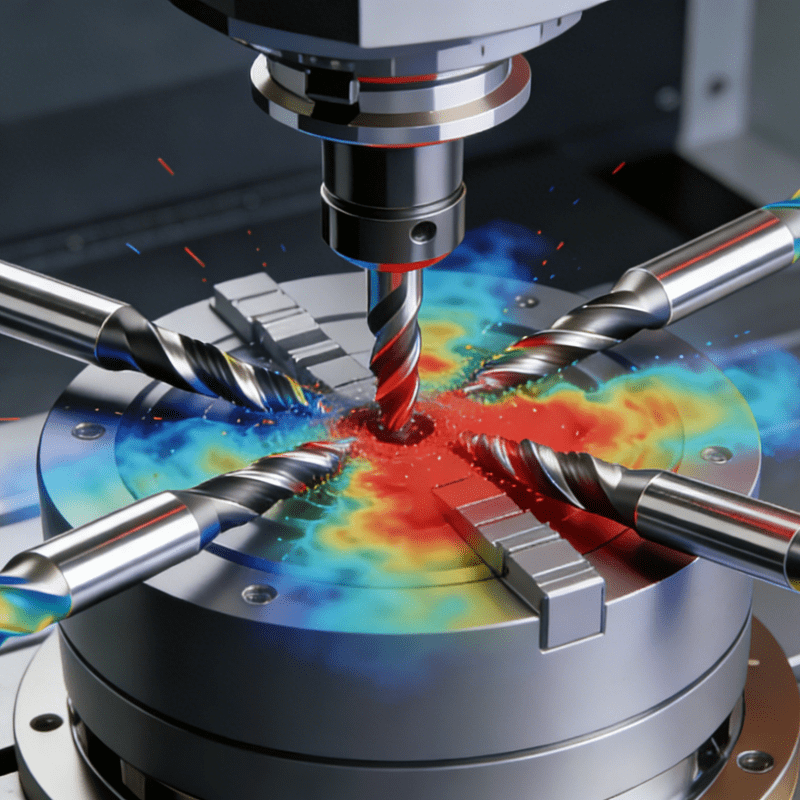

Flexible Manufacturing System

In advancing the smart manufacturing transformation of intelligent machining, flexible manufacturing systems have significantly improved the adaptability of production lines through modular design and intelligent control technology. The system leverages the IoT to achieve seamless connectivity between devices, enabling intelligent machine tools to quickly switch machining tasks and flexibly respond to low-volume customized demands. A typical example is the integration of Автоматично подаване и сглобяване на катарами equipment into flexible production lines: by virtue of the system’s intelligent scheduling and parameter self-optimization capabilities, the equipment can automatically adjust feeding speeds, clamping positions and assembly procedures when switching between different types, specifications or materials of buckles, reducing the product changeover time from hours to minutes and effectively meeting the diversified customization needs of industries such as automotive parts and consumer electronics. For example, through automated scheduling and parameter optimization, enterprises have reduced product changeover time and improved equipment utilization rates. Combined with Digital Twin technology, production changes can be pre-validated in a virtual environment to further optimize resource allocation. This dynamic adjustment mechanism not only supports the processing of diversified orders, but also lays a technical foundation for subsequent cloud collaborative manufacturing, contributing to the improvement of overall efficiency.

Cloud Collaborative Manufacturing

Building on flexible manufacturing systems, cloud collaborative manufacturing integrates data from intelligent machining equipment through cloud computing platforms, enabling cross-regional remote monitoring and real-time collaboration. By constructing a unified cloud system, enterprises can centrally manage production plans across multiple factories, optimize resource scheduling, and facilitate collaborative decision-making in design, production and supply chains. The deployed cloud collaboration solutions support real-time data sharing, enabling efficient linkage of intelligent equipment in different factory premises, which has significantly shortened order response time and reduced logistics costs. This model not only improves information transparency, but also provides scalable technical support for the transformation to smart manufacturing.

Win-win Outcome in Efficiency and Cost

The comprehensive effect of this series of digital transformation measures—realizing equipment interconnection, production process visualization, AI quality control, flexible manufacturing systems and cloud collaborative manufacturing—is ultimately reflected clearly in the achievement of dual goals: improved efficiency and optimized costs. Practices of industry-leading manufacturers have shown that the systematic application of IoT and Digital Twin technologies to transform intelligent machining processes has not only significantly shortened equipment downtime and waiting time, optimized machining parameters, but also generally boosted overall production efficiency by about 30%. Meanwhile, benefiting from the high transparency of the production process and the real-time early warning and interception of quality defects by AI, raw material waste has been significantly reduced, equipment maintenance has shifted from passive to predictive maintenance, and coupled with the advantage of rapid product changeover brought by flexible systems, operational costs have been effectively reduced by approximately 20%. This dual improvement in efficiency and cost has brought considerable return on investment for manufacturing enterprises and laid a solid foundation for sustained innovation.

Through the in-depth integration of technologies such as IoT equipment interconnection and Digital Twin visualization, the field of intelligent machining has achieved substantive breakthroughs in its transformation to smart manufacturing. Equipment interconnection and cloud collaborative manufacturing have built an efficient production network, while AI quality control and flexible manufacturing systems have enhanced process flexibility, jointly driving a significant improvement in production efficiency. Practical cases of enterprises such as Sany Heavy Industry and Gree Electric Appliances have confirmed that this digital transformation has not only achieved a 30% increase in production efficiency and a 20% reduction in operational costs, but also provided a replicable technical framework for the upgrading of the manufacturing industry. In the future, the continuous optimization of these development paths will further strengthen the intelligence level of intelligent machining, helping the industry move towards a higher stage of sustainable development.

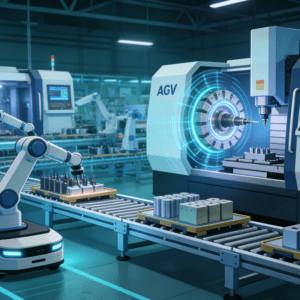

Robots realize the automated assembly of automotive connectors