In the era of Industry 4.0, where agile manufacturing and rapid product customization define competitiveness, traditional vibratory feeders—long workhorses of automated production—are increasingly strained. While they outpace manual feeding in speed and efficiency, their rigidity, unreliability, and difficulty integrating into dynamic systems have become critical bottlenecks. To bridge this gap, EPF Automation developed Supata: an integrated flexible feeding module that marries robotics, AI-driven vision, and smart controls, redefining adaptability in part handling for modern production lines.

Vibratory feeders rely on gravity and vibrations to align small parts during assembly, a method once celebrated for automating repetitive tasks. Yet their one-size-fits-one-part design makes them ill-suited for today’s small-batch, multi-variant production. Frequent reconfigurations are cumbersome, downtime is excessive, and their mechanical rigidity clashes with the need for agile, quickly retooled lines. These limitations spurred EPF Automation to engineer a holistic solution that retains the speed of automation while infusing unprecedented flexibility.

The Supata System: A Unified Approach to Flexible Feeding

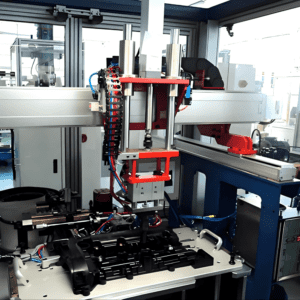

Supata integrates four core components—feeding, vision, robotic handling, and a smart control system—into a modular solution designed for precision-critical industries: automotive, medical, electronics, and technical manufacturing.

At its core is a vibratory smart feeder, comprising a vibrating table and hopper, capable of handling parts from 10 mm to 250 mm in size and 25 g to 350 g in weight. This versatility eliminates the need for part-specific tooling, allowing seamless transitions between components of varying shapes, sizes, and materials.

The system’s AI-powered vision module is a game-changer. Equipped with advanced algorithms and a high-resolution camera, it identifies and locates randomly oriented parts on the vibratory plane, then relays precise coordinates to the robot for picking. This not only ensures accuracy but also simplifies reconfiguration for new parts—operators can reprogram the system in minutes. Integrated quality control checks further reduce errors, boosting productivity by 17–20% compared to traditional setups.

For robotic handling, Supata offers customizable options: six-axis, SCARA, or collaborative robots from Shibaura Machine (formerly Toshiba Machine Robot). SCARA robots excel in high-speed, small-scale pick-and-place tasks with four-axis precision, while six-axis models provide superior articulation for intricate, multi-directional operations. This flexibility lets manufacturers tailor the system to their specific workflow demands.

The control and monitoring system (CMS), built on edge-computing technology, embodies Industry 4.0 principles. It centralizes operations through a user-friendly HMI and enables remote monitoring, allowing operators to track performance and troubleshoot from anywhere—critical for maintaining uptime in distributed facilities.

Seamless Integration for Agile Production

Supata’s design prioritizes ease of integration into existing or new lines. Its rugged, durable chassis comes in fixed or mobile configurations with multiple docking stations, adapting to diverse workshop layouts. This plug-and-play approach avoids the complexity of piecing together standalone components, a common headache with traditional vibratory feeders.

Key operational advantages include consistent cycle times (up to one part per second), a broad material/geometry range, and single-interface control—simplifying training and daily use. For manufacturers juggling frequent product changes, these features translate to minimal downtime and maximum adaptability.

Future-Proofing Manufacturing with Flexibility

Modern manufacturing demands systems that can keep pace with fluid production schedules, frequent design tweaks, and small-batch runs. Supata rises to this challenge: its AI-driven adaptability, modular design, and remote monitoring capabilities make it ideal for dynamic environments. Whether handling a sudden part redesign or scaling to new product lines, the system remains agile—no costly retooling required.

As Industry 4.0 evolves, the ability to balance speed, precision, and flexibility will separate leaders from laggards. Supata isn’t just a feeding solution; it’s a cornerstone of future-ready production lines—empowering manufacturers to cut costs, reduce errors, and stay ahead in an era of constant change.

Advantages of flexible automatic buckle feeding and assembling machines

What benefits do flexible automatic buckle feeding and assembling equipment bring to intelligent manufacturing?