Table of Contents

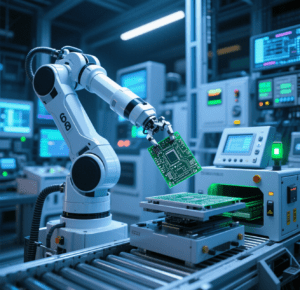

Toggle6-Axis Robotic Loading/Unloading System: Redefining Flexibility in Automated Material Handling

In modern manufacturing, the ability to efficiently load and unload components into machines—from CNC lathes to injection molders—dictates production speed, quality, and cost. Manual handling is slow, error-prone, and unsafe, while 4-axis systems struggle with complex 3D geometries. Enter the 6-Axis Robotic Loading/Unloading System—a versatile solution engineered to tackle these challenges. By combining full 3D dexterity, precision positioning, and adaptive intelligence, this system transforms material handling into a streamlined, high-performance process for industries ranging from automotive to electronics.

Why 6-Axis? The Power of Full 3D Mobility

Six-axis robots offer 6 degrees of freedom (6DOF), enabling movement in all directions and rotations—a game-changer for complex part handling:

1. Неограничен контрол на ориентацията

Unlike 4-axis SCARA robots (limited to planar motion), 6-axis arms rotate freely around X, Y, Z axes and pitch, yaw, roll angles, allowing:

- Angled Pickup/Placement: Grasp parts at 45° from conveyor belts or insert them into angled machine fixtures with ±0.1° accuracy.

- Complex Path Navigation: Maneuver around obstacles in tight workcells, ideal for crowded CNC machining environments.

2. Precision Meets Power

With payloads ranging from 5kg (for delicate electronics) to 50kg (heavy automotive parts) and repeatability of ±0.02mm, 6-axis systems handle both tiny screws and large engine blocks with equal precision.

3. Rapid Changeover for High-Mix Production

Modular tooling and software-driven part recipes let the system switch between 100+ part types in <15 минути—critical for industries embracing mass customization.

Core Technologies: The Anatomy of a Smart Loading System

1. 3D Vision-Guided Navigation

A stereo vision system with AI-powered depth sensing acts as the robot’s “eyes,” solving real-world variability:

- Chaotic Bin Picking: Identifies randomly oriented parts in bins (e.g., castings, forgings, or injection-molded components) with 99.5% accuracy, even for shiny or reflective surfaces.

- Оценка на позата в реално време: Calculates part position (X-Y-Z) and orientation (roll-pitch-yaw) to within 5 мм/0,5°, ensuring seamless alignment with machine chucks or fixtures.

Example: In a die-casting plant, the system picks irregularly shaped automotive transmission cases from a bulk bin and loads them into CNC mills without manual alignment.

2. Force-Torque Sensing for Delicate Handling

A 6-axis force-torque sensor ensures safe, precise interactions with parts and machines:

- Adaptive Gripping: Applies 2–50N of grip force based on part material (e.g., 5N for plastic housings, 30N for steel shafts), preventing damage.

- Collision Detection: Instantly stops motion if resistance exceeds preset limits (e.g., during tool insertion), protecting both the robot and machine.

3. Modular End-of-Arm Tooling (EOAT)

Quick-release grippers make the system infinitely adaptable:

- Хибридни хващачи: Combine vacuum suction (for smooth surfaces) and mechanical fingers (for textured parts) in one tool, ideal for smartphone casings with both metal and glass components.

- Magnetic/Electrostatic Tools: Secure ferrous or non-ferrous parts without marks, critical for aerospace components requiring scratch-free handling.

- Tool Change Time: <5 minutes, with a digital tool library storing configurations for hundreds of part types.

4. Smart Integration Software

The system’s software ecosystem enables seamless factory connectivity:

- Machine Tool Integration: Communicates with CNCs, injection molders, and 3D printers via protocols like MTConnect or OPC UA, triggering automated cycles.

- AI-Powered Path Planning: Machine learning algorithms optimize movement to reduce cycle times by 10–15%, even for complex multi-machine cells.

Transforming Industries: Applications in Action

1. Automotive Manufacturing: Engine Component Machining

In a cylinder head production line:

- The robot picks raw aluminum castings (15kg) from pallets using mechanical grippers, orienting them for precision milling.

- After machining, it unloads finished parts and inspects for surface defects via integrated vision, reducing manual inspection time by 80%.

Result: Cycle time per part drops from 90 seconds (manual) to 35 seconds, with 99.8% loading accuracy—boosting daily output by 200 components.

2. Electronics: Precision Handling of Complex PCBs

In a high-mix PCB assembly plant:

- Vacuum grippers gently lift 0.8mm-thick PCBs with delicate SMD components, placing them into reflow ovens with ±0.05mm accuracy.

- Vision system reads QR codes to validate part numbers, eliminating misloading errors that cause costly rework.

Case Study: A leading EMS provider achieves 99.9% first-pass yield, saving $1.5M annually in scrap and rework costs.

3. Metalworking: Heavy-Duty Stamping Automation

For a steel stamping press handling 30kg metal sheets:

- Robust grippers with anti-slip coatings secure sheets during transport, while force sensing ensures flat placement on the press bed.

- AI algorithms predict optimal gripper positions to minimize sheet deformation, improving stamping quality by 40%.

6-осни срещу традиционни методи: Разбивка на производителността

| Metric | 6-Axis Robotic System | Manual Handling | 4-Axis Robot | Semi-Automatic Loader |

| 3D Orientation Control | Yes (6DOF) | Limited (2–3DOF) | No (4DOF) | No (fixed angles) |

| Payload Capacity | 5–50kg (modular tools) | 5–20kg (risky) | 5–20kg (planar only) | 10–30kg (rigid setup) |

| Positioning Accuracy | ±0.02mm/±0.1° | ±1 мм/±5° (променлива) | ±0,05 мм (само планарно) | ±0,5 мм/±2° |

| Changeover Time | <15 минути | 60+ minutes | 30 minutes | 120+ minutes |

| Cost (USD, medium payload) | $150k–$300k | Labor-intensive | $80k–$150k (limited flexibility) | $100k–$200k (inflexible) |

The Business Case: From Bottleneck to Competitive Edge

1. Rapid ROI Through Efficiency and Safety

- Labor Savings: Replaces 2–5 operators per line, saving $80k–$150k annually in labor costs (even in regions with moderate wages).

- Uptime Boost: 98% operational reliability (vs. 70% for manual lines) thanks to predictive maintenance and error-proofing.

- Quality Assurance: 90% fewer misloading errors reduce scrap and machine damage, critical for high-value parts like aerospace forgings.

2. Производство, готово за бъдещето

- IoT Integration: Feeds real-time data (cycle times, gripper status, error logs) to MES systems for predictive analytics and production optimization.

- Collaborative Safety: Equipped with 3D safety scanners, works alongside humans in shared workcells—ideal for hybrid manual-automated environments.

- Scalability: Easily integrates with existing conveyors, AGVs, or storage systems, enabling seamless expansion from single-machine automation to full factory lines.

The Future of Loading/Unloading: Where Dexterity Meets Intelligence

As Industry 4.0 accelerates, the 6-Axis Robotic Loading/Unloading System evolves with:

- Self-Optimizing Algorithms: Machine learning continuously refines pick-and-place strategies based on real-time performance data, improving efficiency by 5–10% over time.

- Zero-Setup Part Onboarding: On-tool sensors auto-detect new part dimensions, eliminating manual programming for new SKUs.

- Sustainability Focus: Energy-efficient drives and regenerative braking reduce power consumption by 25%, aligning with global green manufacturing goals.

In an era where flexibility and precision are non-negotiable, the 6-Axis Robotic Loading/Unloading System is more than a machine—it’s a strategic asset. It turns the mundane task of material handling into a competitive advantage, empowering manufacturers to build faster, smarter, and with unmatched adaptability.

#6Axis Robotic Loading #Automated Material Handling #Precision CNCLoading Unloading