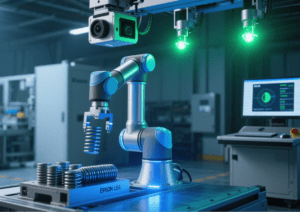

4-Axis Robotic Vision-Guided Spring Placement System: Elevating Precision and Efficiency in Automated Assembly

In modern manufacturing, springs serve as critical mechanical components in industries ranging from automotive to medical devices, requiring precise placement to ensure functional reliability. Traditional spring placement methods— —suffer from limitations like inconsistent accuracy (±0.5mm or worse), slow cycle times (5–10 seconds per spring), and poor adaptability to diverse spring types (e.g., compression, torsion, or micro springs). The 4-Axis Robotic Vision-Guided Spring Placement System emerges as a transformative solution, combining the speed of 4-axis robotics with the precision of machine vision to automate spring handling in high-mix, high-precision assembly lines. This article explores its technical architecture, industrial applications, and role in driving smart manufacturing innovation.

- Core Technical Architecture: Synergy of Speed and Precision

The system integrates 4-axis SCARA robots (Selective Compliance Assembly Robot Arm) with AI-powered vision systems to achieve rapid, accurate spring placement in planar applications (X, Y, Z axes + rotation). Its modular design comprises three interdependent subsystems:

- High-Speed 4-Axis Robot Manipulation

SCARA robots (e.g., Epson LS6, Yamaha YK-XG) are ideal for this application due to:

- Planar Speed Dominance: Achieving pick-and-place speeds of 200+ springs per minute with repeatability of ±0.02mm, 3–5 times faster than manual operations

- Compliance Control: Built-in force sensors adjust grip pressure in real-time, protecting delicate springs (e.g., 0.1mm wire diameter) from deformation while ensuring secure handling

- Compact Footprint: Vertical Z-axis stroke (up to 300mm) and horizontal reach (500–1,000mm) optimize space in tight assembly cells

- Vision-Guided Positioning & Inspection

A dual-camera setup (overhead 2D camera + side-view 3D sensor) provides multi-faceted spring analysis:

- Positioning Accuracy: Industrial cameras (12MP+ resolution) with telecentric lenses achieve sub-micron detection, correcting robot positioning for springs placed with ±0.1mm offset on conveyor belts

- Spring Orientation Detection: Deep learning algorithms identify critical features—such as hook angles in torsion springs or coil ends in compression springs—with 99.9% accuracy, eliminating misorientation errors

- Defect Screening: Real-time inspection for cracks, diameter deviations, or surface coatings, rejecting non-conforming springs before placement and maintaining a 99.8% assembly yield rate

- Intelligent Control Software

The system’s digital backbone enables seamless integration and adaptive operation:

- Recipe Management: Stores 500+ spring specifications (length, wire diameter, force characteristics) with one-click changeover in <10 seconds, ideal for high-mix production

- Real-Time Synchronization: Ethernet/IP or Profinet connectivity aligns robot motion with conveyor speed (up to 2m/s), enabling dynamic pick-and-place without stopping the line

- Проследимост на данните: Records placement coordinates, force applied, and inspection results for every spring, supporting ISO 9001 compliance and post-assembly quality 追溯

- Industrial Applications: Solving Diverse Spring Placement Challenges

- Automotive Assembly: High-Volume, High-Reliability Demands

In engine valve trains, suspension systems, and transmission components, the system excels at:

- Valve Spring Insertion: Placing conical valve springs (5–50mm height) into cylinder heads with ±0.05mm vertical alignment, critical for maintaining proper compression ratios

- Clutch Spring Alignment: Positioning torsion springs in automotive clutches with precise angle control (±0.2°), reducing gear engagement noise and wear

Case Study: A leading automotive Tier 1 supplier reduced spring placement defects by 75% and increased assembly line throughput by 40% after deploying 50 systems across its transmission plants.

- Electronics Manufacturing: Micro Spring Precision

For consumer electronics (smartphones, wearables) and industrial controls:

- Connector Spring Placement: Handling micro springs (0.5–2mm diameter) in SIM card slots or battery connectors with zero-tolerance for misalignment, ensuring reliable electrical contact

- Wireless Charging Spring Alignment: Accurately positioning planar coil springs in charging modules, maintaining optimal air gaps for efficient power transfer

- Anti-Static Design: Conductive gripper surfaces and ionizing blowers prevent electrostatic damage to sensitive electronic components

- Medical Device Assembly: Sterile Environments and Regulatory Compliance

In syringe pumps, orthopedic implants, and diagnostic equipment:

- Sterile Spring Handling: Stainless steel 316L robot arms and ISO 8 cleanroom-compatible coatings enable placement of springs used in drug delivery systems, meeting FDA and EU MDR requirements

- Microsurgical Instrument Springs: Positioning ultra-small torsion springs (0.05mm wire diameter) in laparoscopic tools with nanometer-level precision, ensuring smooth mechanical operation

- Industrial Machinery: Heavy-Duty Spring Integration

For agricultural equipment, construction machinery, and industrial valves:

- Large Compression Spring Placement: Handling springs up to 200mm in diameter and 500mm in length using dual gripper modules, with force control to overcome pre-load tensions of 1,000N+

- Multi-Spring Matrix Assembly: Programming custom patterns (linear, grid, or circular) for complex spring arrays in vibration-damping systems, reducing setup time by 60%

III. Competitive Advantages Over Traditional Systems

| Performance Indicator | Manual/ Semi-Automatic Placement | 4-Axis Vision-Guided System |

| Placement Speed (per spring) | 5–10 seconds | 0.8–1.5 seconds |

| Positioning Accuracy | ±0.5mm | ±0.02mm (planar), ±0.1mm (Z-axis) |

| Changeover Time (new spring) | 30+ minutes | <10 seconds (recipe-based) |

| Defect Rate | 0.3–0.5% | <0.02% |

| Labor Reduction (per cell) | 2–3 operators | 1 supervisor (remote monitoring) |

| Flexibility (spring types) | Limited to 5–10 types | 500+ types with adaptive grippers |

- Technological Innovations and Future Trends

- AI-Driven Self-Optimization

Machine learning algorithms analyze historical placement data to:

- Predict optimal gripper pressure for new spring materials (e.g., titanium vs. stainless steel)

- Adjust robot acceleration profiles to minimize vibration during high-speed moves, improving stability by 30%

- Identify subtle wear patterns in gripper tips, triggering maintenance alerts before defects occur

- 3D Vision Upgrade for Complex Geometries

Integrating structured light or ToF (Time-of-Flight) sensors enables:

- Accurate placement of springs on curved surfaces (e.g., automotive dashboard components)

- Detection of 3D features like helical angles in volute springs, expanding application to aerospace and defense sectors

- Collaborative Robotics Integration

Dual-arm cobots (e.g., Universal Robots UR10e) with vision guidance are being developed for:

- Shared workspaces where humans and robots collaborate on hybrid assembly tasks

- Delicate operations requiring both precision (robot) and tactile judgment (human), such as spring-loaded component alignment

- Energy-Efficient Design

Newer systems incorporate:

- Regenerative drives to recover 25% of braking energy during Z-axis descent

- Sleep modes for idle robots, reducing power consumption by 40% in multi-shift operations

- Lightweight carbon fiber robot arms, cutting mechanical stress and extending component lifespan

Conclusion

The 4-Axis Robotic Vision-Guided Spring Placement System represents a leap forward in automated assembly, addressing the conflicting demands of speed, precision, and flexibility in spring handling. By eliminating manual errors, reducing changeover times, and enabling data-driven quality control, it becomes a strategic asset in Industry 4.0 environments. As manufacturing evolves toward mass customization and zero-defect production, these systems will continue to advance—integrating AI, 3D vision, and collaborative capabilities—to meet the ever-growing complexity of modern assembly processes.

Keywords: 4-Axis Robotic Spring Placement, Vision-Guided Precision Assembly, SCARA Robot Spring Handling, AI-Powered Spring Inspection, High-Speed Spring Positioning System, Automated Micro Spring Placement, Industrial Robot Vision System, Smart Manufacturing Spring Solutions, ISO Compliant Spring Handling, Force-Control Spring Gripping Technology

#Automotive Valve Spring Insertion #Cold Formed Spring Placement System #Force-Controlled Spring Grippers