Event Overview: On-site Highlights and Flagship Harvester Debut

Recently, Zoomlion’s new paddy field agricultural machinery product appreciation event was successfully held in Changde, Hunan Province. A customer group consisting of over 500 large grain growers and professional operators from Hubei and Hunan provinces participated on site. A number of flagship products including the 2026 model crawler harvesters, power-shift tractors and intelligent assisted driving transplanters made their upgraded debut, receiving high praise and positive feedback from the customer group, with over 200 units ordered on the spot.

The Zoomlion PL80-S crawler harvester, which has undergone 102 targeted enhancements and 16 optimization upgrades, became the absolute highlight of the event. The model has carried out comprehensive material and process upgrades on systems such as threshing and cleaning, header, chassis and bearings of key parts, greatly improving reliability. It is equipped with a 140-horsepower engine, standard practical configurations including a three-disc drum, a 1.9-cubic-meter large-capacity grain tank, an extended grain unloading cylinder and an electric reversible chopper. It can also be optionally fitted with intelligent functions such as infinitely variable speed of reel, multi-mode steering, automatic header lifting and automatic work load control, fully meeting the diversified needs of field operations.

Other New Offerings and Factory Visit: Enhancing Customer Trust

In addition, other new products such as Zoomlion’s RK1004, CH1204 and RN1404 series wheeled tractors as well as intelligent assisted driving transplanters also attracted much attention. Among them, the CH1204 power-shift tractor, specially developed for domestic paddy field areas, adopts electronically controlled power-shift technology, featuring easy and comfortable operation. By integrating multi-sensor signals and independently developed multi-protection shift algorithms, it achieves smooth and gentle shifting process, accurately matching the operating habits of operators.

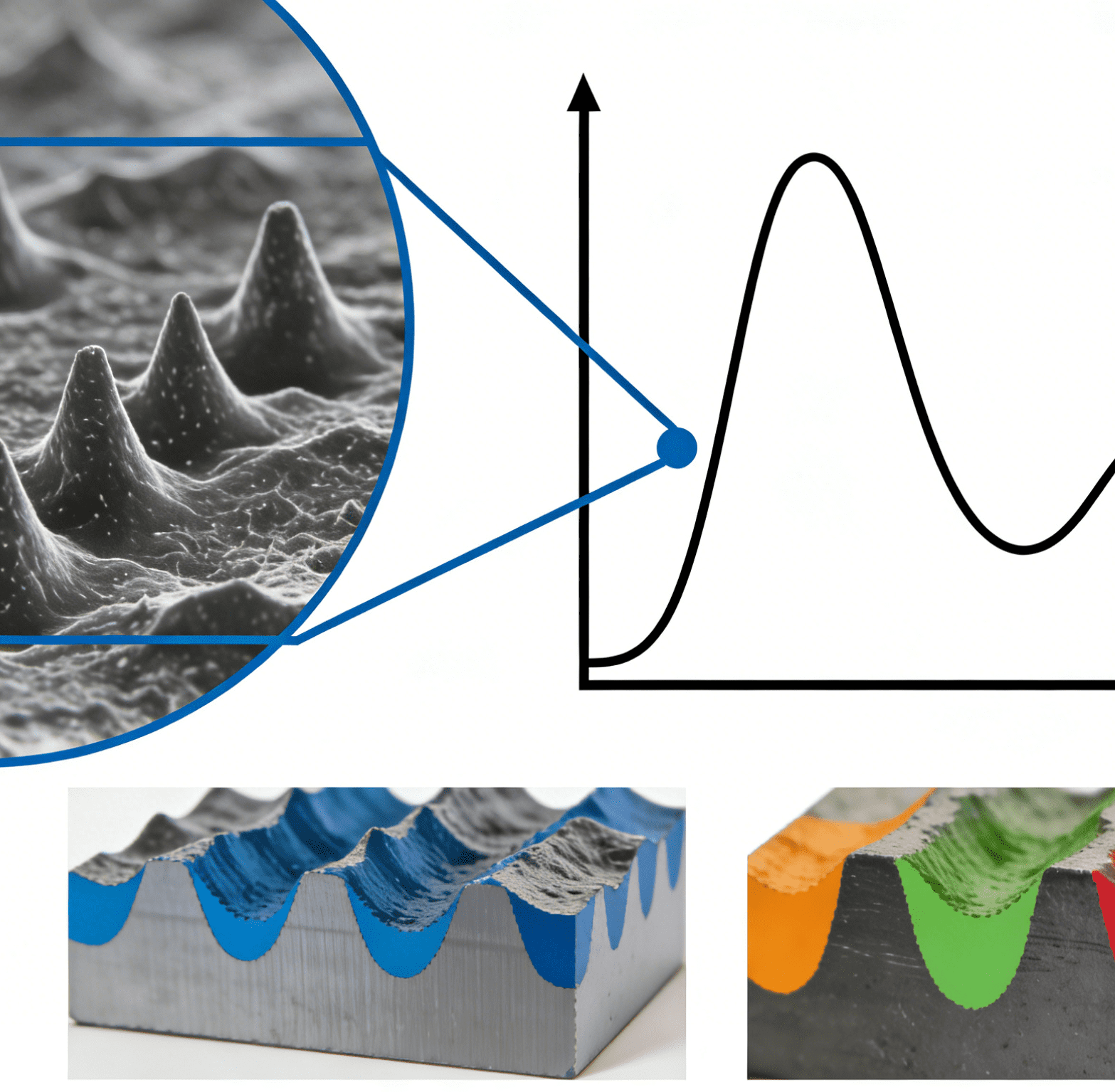

During the event, the customer group visited the Changde Factory of Zoomlion Agricultural Machinery Co., Ltd., inspected the production workshops on site, directly experienced the stringent quality control system and advanced manufacturing processes, and thus gained greater trust in the quality of Zoomlion’s agricultural machinery products. Notably, the آلة تجميع الملامسات applied in the core electrical components production process became a focus of on-site observation—this automated equipment realizes precise assembly of contactors through multi-station collaborative operation and real-time precision detection modules, ensuring the stability of electrical control systems for harvesters, tractors and other products. The application of such professional assembly equipment demonstrated Zoomlion’s strict control over core component manufacturing, further strengthening customers’ recognition of product quality.

What is the work done using automated equipment and machines called?