On August 28, 2025, the Lathe Branch of China Machine Tool & Tool Builders’ Association and Luoyang Xincheng Precision Machinery Co., Ltd. jointly held the “Technical Exchange Meeting of Lathe Branch & Open Day of Luoyang Xincheng Factory”. Wang Xu, Executive Vice President of the Association, attended and delivered a speech. More than 50 representatives from the Association and member units of the Lathe Branch participated in the event to discuss the path of high-quality development of the machine tool industry.

Vice President Wang Xu’s Speech: Affirming Xincheng’s Achievements and Emphasizing the Importance of Technical Sharing and Innovative Cooperation

In his speech, Wang Xu, Executive Vice President of the Association, affirmed Luoyang Xincheng’s achievements in product innovation, corporate culture construction and intelligent application. He pointed out that this event hosted by the Branch is a good practice to build a bridge between supply and demand, which is worth promoting. Wang Xu emphasized that against the background of manufacturing transformation and upgrading, technical sharing and innovative cooperation are the key for the machine tool industry to break through bottlenecks and move towards high-end.

Deputy Secretary-General Chen Hongjun’s Report: Interpreting the Situation of Lathe Industry and the Practical Direction of the Branch’s Work

Chen Hongjun, Deputy Secretary-General of the Lathe Branch, delivered a report on “Analysis of Lathe Industry and Practical Work of the Branch”. Through a large amount of industry data, he interpreted the latest situation of the lathe industry, clarified the direction of the Lathe Branch in assisting industrial upgrading and industrial chain collaboration, and introduced the specific help provided by the Lathe Branch to member units in recent years as well as its efforts for the development and progress of the industry.

Luoyang Xincheng Releases New BMT Live Tool Holder, with Patent Technology Breaking European Monopoly

Ding Xiangyang, Chairman of Luoyang Xincheng, introduced the basic situation of the enterprise, and jointly released the new BMT live tool holder with Chang Junjie, Deputy General Manager. Luoyang Xincheng obtained the national invention patent for “Elastic Structure Anti-backlash Key” on August 1, breaking the European monopoly and improving the repeated installation positioning accuracy of SFX live tool holder from 8-9μm to 3-4μm.

Themed Sharing and Exchange: Focusing on Industrial Upgrading and Management Innovation, Sharing Practical Achievements

The afternoon session focused on the theme of “Industrial Upgrading, Management Innovation, Digital Empowerment, and Lean Management” for sharing and exchange. Responsible persons from Luoyang Xincheng, Sentai Inge, Guilin Guanglu, and Luoyang Ruige respectively introduced their enterprises’ practical experience and achievements in product innovation, system construction, digital empowerment, and refined management, for representatives’ reference and learning.

Technical Exchange on Application of Live Tool Holders: Experts Discuss Development Direction, and Xincheng’s Detection Method is Recognized

At the subsequent “Technical Exchange on Application of Live Tool Holders”, participating experts expressed their opinions on the future direction of Xincheng’s live tool holders and exchanged detection methods. The noise analysis detection method demonstrated on-site by Luoyang Xincheng was recognized.

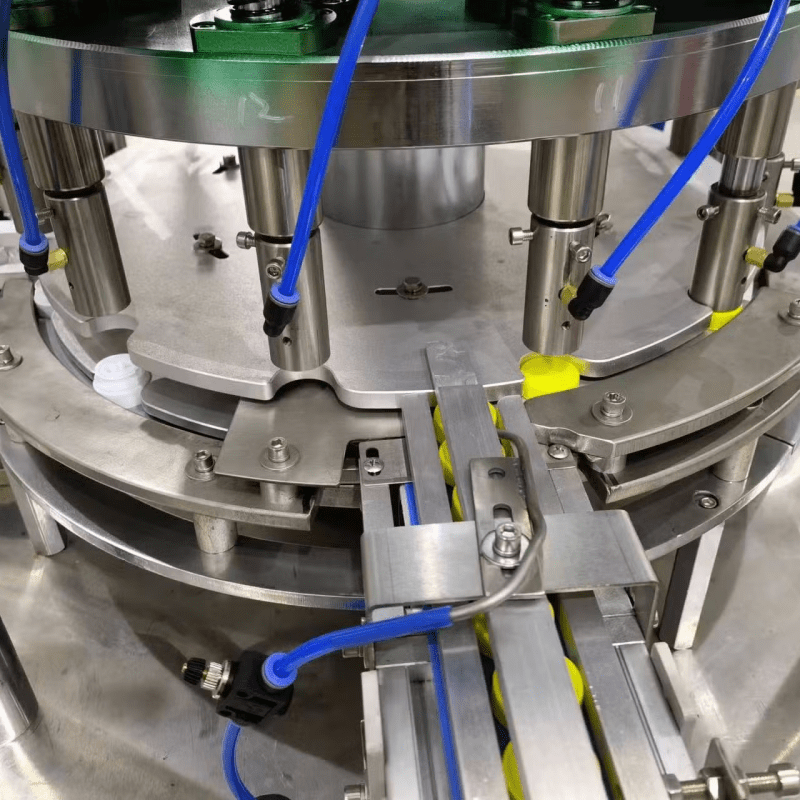

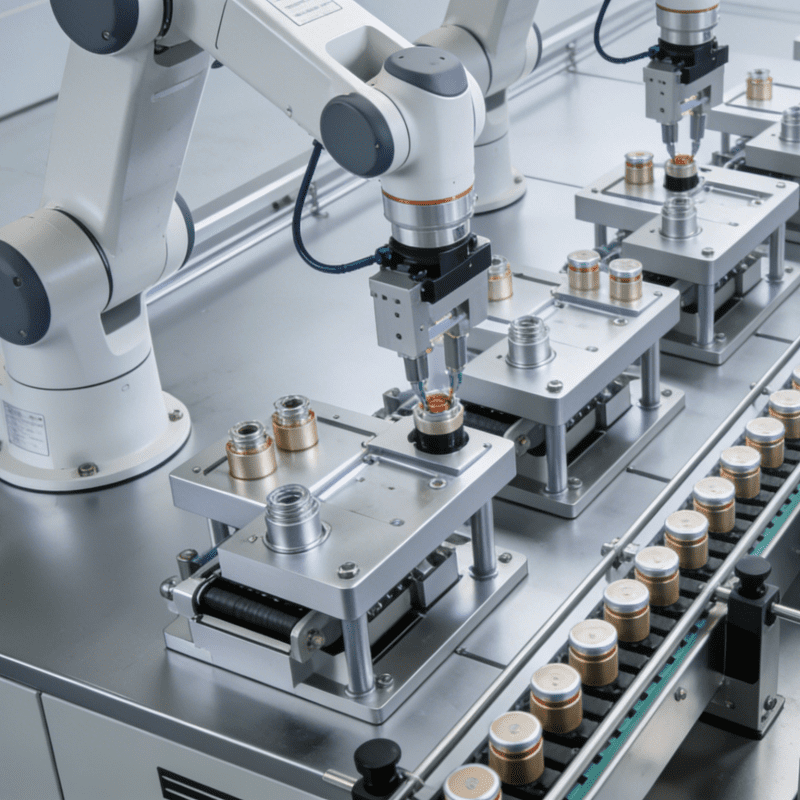

Factory Visit: Experiencing Fine Manufacturing Strength, with Intelligent Handling System as a Highlight

The meeting organized representatives to visit Luoyang Xincheng Factory in 4 groups to comprehensively experience the relevant manufacturing links and fine manufacturing strength of its products. The on-site displayed Robotic Irregular-Shaped Metal Part Removal System was particularly eye-catching. Through 3D visual recognition and flexible grasping technology, the system can accurately adapt to irregular metal workpieces of different curvatures and sizes, realizing unmanned handling and transfer in the processing of core components of live tool holders, which improves the process connection efficiency by 40% and fully demonstrates the enterprise’s technical accumulation in the field of intelligent manufacturing.

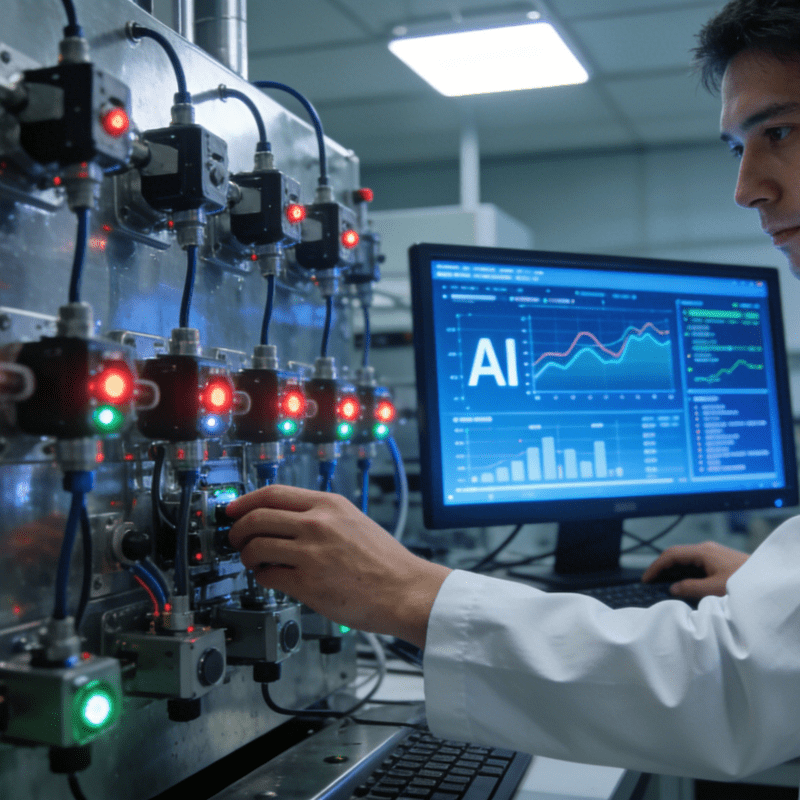

Artificial Intelligence Five-sided Automatic Assembly Machine

Optimization of the five-sided automatic assembly machine by AI