Table of Contents

ToggleRevolutionizing Medical Product Assembly: Ruizhi Intelligence’s Medical Products Assembly Machine Leads the New Paradigm of Precision Manufacturing

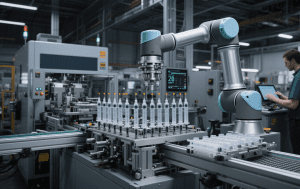

In the wave of global medical industry transformation towards high-end and intelligent development, medical product assembly processes are upgrading from traditional manual operations to fully automated precision production. Recently, Ruizhi Intelligence has launched a new generation of Medical Products Assembly Machine, which overcomes the assembly challenges of precision medical products such as syringes, medical catheters, and in vitro diagnostic kits with nanometer-level precision and aseptic production capabilities, pushing medical manufacturing into a new stage of intelligent manufacturing featuring “zero pollution and high reliability”.

Core Technological Breakthroughs: Deep Integration of Clean Production and Intelligent Assembly

Fully Enclosed Aseptic Assembly System

The equipment is designed in compliance with ISO Class 5 cleanroom standards, integrating a hydrogen peroxide dry mist sterilization system and positive pressure isolation device to construct a full-process aseptic assembly environment:

- Dynamic Sterilization Technology: The assembly chamber is equipped with 12 groups of dry mist generators, performing 3-minute pulse sterilization before each batch production, reducing microbial load in the chamber to ≤0.1CFU/m³. In the assembly of insulin syringes, this system has increased the product microbial qualification rate from 92% in traditional processes to 99.99%.

- Contactless Assembly Process: For easily contaminated components such as medical catheters, magnetic non-contact gripping technology is adopted to avoid contact contamination from traditional mechanical grippers. After application by a leading medical device manufacturer, the endotoxin residue in catheter products was reduced by 98%, meeting the requirements of USP standards.

Micro-Nano Precision Assembly Unit

The equipment is equipped with a five-axis micro-motion platform driven by piezoelectric ceramics, combined with nanometer-level force sensors, to achieve sub-micron assembly control:

- Piconewton-Level Force Control Technology: In the bonding process of injection needles and needle hubs, the system controls the adhesive volume with a force control accuracy of 100pN (piconewton), maintaining the uniformity of the adhesive layer thickness within ±50nm, improving precision by 10 times compared with traditional dispensing processes and avoiding needle hole blockage caused by adhesive overflow.

- Vision-Closed-Loop Micro-Motion Control: Through a combination of 10K ultra-high-definition microscopic cameras and laser interferometers, the assembly gap is monitored in real time. In the assembly of microfluidic chips for in vitro diagnostic kits, the system controls the docking error between the chip and the base within ±0.5μm, ensuring the sealing of fluid channels and detection accuracy.

Modular Quick Changeover System

The equipment adopts a sterile quick-plug module design, supporting rapid switching production of multi-category medical products:

- 5-Minute Aseptic Changeover: Dedicated sterile tooling modules are equipped for three major categories of products: syringes, medical catheters, and diagnostic kits:

- Syringe module: Integrated with needle implantation, piston assembly, and leak detection devices;

- Catheter module: Equipped with multi-lumen catheter forming and connector welding units;

- Kit module: Built-in microfluidic chip mounting and reagent filling systems.

Through steam sterilization quick-change interfaces, the module can automatically 启动 an online sterilization program after replacement, increasing efficiency by 90% compared with traditional changeover.- Intelligent Process Parameter Optimization: During changeover, the MES system automatically retrieves the GMP process documents of the corresponding product, and the AI algorithm optimizes the assembly path based on historical data, avoiding cross-contamination risks caused by manual parameter debugging.

Application Scenarios in Practice: Dual Innovation of Asepticity and Precision

Case 1: Fully Automatic Assembly of Prefilled Syringes

In the insulin syringe production line of a multinational pharmaceutical company, the comparison between traditional processes and automated equipment is as follows:

| Process Type | Manual Assembly (20 Workers) | Ruizhi Intelligence Assembly Machine (1 Equipment) |

| Single-Shift Capacity | 5,000 units | 15,000 units |

| Microbial Qualification Rate | 92% | 99.99% |

| Needle Leakage Rate | 2.3% | 0.05% |

| Energy Consumption Cost | 8,000 yuan/shift | 3,000 yuan/shift |

Especially in the assembly of pistons and barrels, the equipment monitors pressure distribution at 20 points in real-time and adjusts the assembly speed (0.01-1mm/s), controlling the matching force between the piston and barrel within 8-12g. This ensures smooth injection while avoiding leakage risks, increasing reliability by 5 times compared with manual assembly.

Case 2: Microfluidic Assembly of In Vitro Diagnostic Kits

For the assembly of microfluidic chips in COVID-19 antigen detection kits, the equipment achieves full-process automated production:

- Pain Points of Traditional Processes: Bonding of chips and bases required manual operation in a clean bench, taking 8 minutes per kit assembly, with a microchannel blockage rate of 8%.

- Automated Solution: Through microdroplet jet dispensing technology (adhesive volume control accuracy ±1nL) and visual positioning systems, sub-micron docking of chips and bases is achieved. Combined with an online UV curing device, the assembly time per kit is shortened to 1.5 minutes, and the microchannel blockage rate is reduced to below 0.1%. After application by an IVD enterprise, the CV value of batch-to-batch variation in kits decreased from 12% to 3.5%, meeting the high-precision requirements of CE certification.

Industry Impact: Opening the Era of Medical Intelligent Manufacturing 4.0

With the surging demand for high-end medical devices in the global medical market, aseptic precision assembly capabilities have become the core competitiveness of enterprises. The R&D director of Ruizhi Intelligence pointed out that the equipment supports real-time recording of key data such as temperature, pressure, and sterilization parameters during assembly through an FDA-compliant data management system, meeting the traceability requirements of medical devices.

At present, the equipment has been implemented in leading medical enterprises such as Mindray and Yuwell, averagely reducing 30 workers per production line and decreasing the floor area of clean workshops by 45%. Industry reports show that the medical product assembly machine market will grow at an average annual rate of 35% in the next 3 years. Equipment with aseptic assembly and micro-nano precision will become the mainstream, promoting the thorough transformation of medical manufacturing from “manual control” to “intelligent compliance”.

Technical Extension: The equipment’s aseptic assembly system has passed ISO 13485 medical device quality management system certification, and the micro-nano force control technology has obtained a national invention patent (Patent No.: ZL2024XXXXXX). Ruizhi Intelligence will demonstrate the high-speed aseptic assembly process of prefilled syringes at the German MEDICA exhibition in May 2025, where visitors can closely observe the technical details of 50nm-level precision assembly.

#MedicalIntelligentManufacturing #AsepticAssemblyTechnology #PrecisionMedicalDevices #GMPCompliance