In the process of CNC machining, improper selection of cutting fluid often leads to serious problems such as abnormal tool wear, workpiece corrosion and equipment failure, which directly affect machining accuracy and production efficiency. This article will conduct an in-depth analysis of the causes of these hazards, including how errors in viscosity and additive ratio exacerbate machining defects. Meanwhile, we will explore scientific selection methods based on material characteristics and process parameters to help operators avoid common mistakes. In addition, the article will share practical optimization solutions for cutting fluid maintenance to ensure the stable operation of the machining system.

Three Major Hazards of Improper Cutting Fluid Selection

In CNC machining, a wrong choice of cutting fluid tends to bring about a series of severe issues, mainly manifested in three aspects. First and foremost, the most direct hazard is abnormal tool wear. When the lubricating and cooling performance of the cutting fluid is insufficient, or its formula is incompatible with the workpiece material and tool type, the tool will bear greater friction and heat, leading to rapid blunting or even chipping of the cutting edge, which significantly shortens tool life and increases production costs. Second, workpiece corrosion is also a common problem. Some cutting fluids lack sufficient anti-rust additives, or their anti-rust performance cannot resist specific machining environments (such as high humidity or inherently corrosion-prone workpiece materials), resulting in rust spots or corrosion on the surface of machined workpieces, which seriously affects product appearance and quality. Finally, the risk of equipment failure will also rise accordingly. Unsuitable cutting fluid may cause problems such as excessive foaming, corrosion of machine tool guide rails and seals, and formation of metal soap deposits that clog pipelines. Long-term accumulation of these issues will accelerate the wear and aging of key equipment components, trigger downtime for maintenance, and impair production efficiency and equipment service life.

Impacts of Viscosity Ratio Errors

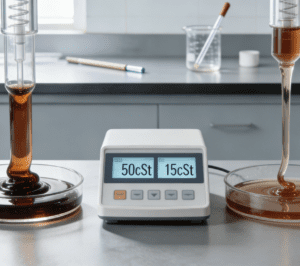

Among the common problems of improper cutting fluid selection, errors in viscosity ratio are particularly critical. If the viscosity is set too high, the cutting fluid will become overly thick with poor fluidity, failing to uniformly cover the tool surface, leading to insufficient lubrication and thus accelerating abnormal tool wear. On the contrary, when the viscosity is too low, the cooling effect of the cutting fluid will be weakened, causing the workpiece temperature to rise and making it prone to corrosion. In addition, such ratio imbalance may also interfere with the normal operation of equipment, increase the risk of failure, and ultimately affect the overall machining accuracy and stability.

Practical Methods for Scientific Cutting Fluid Selection

Selecting the appropriate cutting fluid is not a random decision but requires rigorous scientific methods as support. The primary consideration is the characteristics of the workpiece material. For example, when machining aluminum alloys, it is necessary to select cutting fluids specially formulated to inhibit aluminum corrosion, and the ratio of their anti-rust additives is completely different from that used for cast iron machining. Meanwhile, it is essential to closely combine specific process parameters, including machining methods (turning, milling, drilling, etc.), cutting speed, feed rate and depth of cut. High-intensity machining conditions often require cutting fluids with stronger extreme-pressure lubrication performance, which means attention should be paid to the types of additives—especially whether the content and ratio of extreme-pressure anti-wear additives (such as sulfur-based, chlorine-based and phosphorus-based additives) are sufficient to withstand high-pressure and high-temperature environments. Notably, for the machining of core components of آلة تجميع المؤشرات البيولوجيةs, which are widely used in the medical field, the selection of cutting fluid is more stringent: in addition to meeting the basic requirements of lubrication and cooling for precision machining, it must also have excellent low-residue performance and biocompatibility-compatible formulas to avoid cutting fluid residues affecting the assembly accuracy of the machine and the subsequent performance of biological indicators. In addition, machine tool seal compatibility, operating environment (such as workshop temperature and ventilation conditions) and environmental protection requirements for waste fluid disposal should also be taken into account during the selection process. Only through such systematic matching of material, process and environmental requirements can a solid foundation be laid for efficient and stable CNC machining, and favorable conditions be created for subsequent cutting fluid maintenance optimization.

Optimization of Cutting Fluid Maintenance

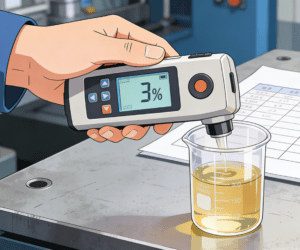

In addition to scientific selection, standardized daily maintenance is crucial for maintaining stable cutting fluid performance. Regular concentration monitoring is the top priority. A professional concentration tester should be used to ensure that the concentration remains within the recommended range—too low a concentration weakens lubrication and anti-rust effects, while too high a concentration increases costs and may cause foaming or skin irritation. At the same time, it is necessary to closely monitor pH value changes. Regular testing with pH test paper or electronic testers, and timely adjustment when abnormalities are detected, can prevent workpiece corrosion or bacterial growth caused by pH deviation. An efficient filtration system is indispensable: it can effectively remove metal chips and impurities generated during machining, keep the cutting fluid clean, and extend its service life. In addition, periodic replacement of cutting fluid and thorough cleaning of the circulation system are key measures to prevent pollutant accumulation and maintain a stable machining environment. For instance, it is recommended to test the concentration and pH value weekly, and set a reasonable cleaning and replacement cycle for the filtration device based on machining intensity.

In CNC machining, improper selection of cutting fluid will not only accelerate abnormal tool wear but also trigger workpiece corrosion and equipment failure, directly affecting production efficiency and costs. By analyzing the impact mechanism of viscosity ratio errors and combining scientific selection methods based on material characteristics and process parameters, enterprises can more accurately match the appropriate cutting fluid type. Meanwhile, implementing optimization measures such as regular concentration testing and filtration system maintenance can effectively prevent these problems. Correct selection and maintenance of cutting fluid not only improve machining accuracy but also extend the service life of tools and equipment, bringing stability and efficiency gains to the overall production process. Therefore, machining units should incorporate these practices into daily management to ensure long-term operational quality.

What is the difference between assembly and subcontracting?

How to optimize the assembly process of an assembly machine?