In an era of growing environmental awareness, the precision CNC machining industry is also facing increasingly stringent environmental requirements. This inevitably leads people to wonder: Will these environmental requirements become a stumbling block to the industry’s innovative development?

In traditional perception, precision CNC machining is often regarded as a representative of high-precision and high-efficiency production, while environmental protection is not its primary concern. However, with the prominence of environmental issues, environmental concerns arising from the machining process—such as cutting fluid pollution, metal waste disposal, and energy consumption—have gradually gained attention. Environmental requirements force enterprises to properly handle these “by-products” of traditional machining models. For example, the use of cutting fluids must comply with strict discharge standards, metal waste needs to be reasonably recycled and reused, and the energy efficiency of production equipment is also brought under regulatory oversight.

Short-Term Challenges: Financial and Resource Pressures of Environmental Compliance

From certain perspectives, environmental requirements seem to pose tangible challenges to the industry. Enterprises may need to invest substantial funds in upgrading equipment and improving processes—such as adopting dry cutting or minimal quantity lubrication technologies to reduce cutting fluid pollution—adding significant R&D and procurement costs. For small and medium-sized enterprises, this financial burden may restrict investment in core innovation areas like new tool materials or process optimization.

Furthermore, frequent updates to environmental regulations require enterprises to allocate more human and management resources to compliance—including establishing dedicated environmental departments—potentially diverting focus from core business innovation.

Long-Term Impetus: Environmental Demands Drive Cross-Disciplinary Innovation

From a macroscopic and long-term perspective, environmental requirements act as a powerful catalyst for industry innovation:

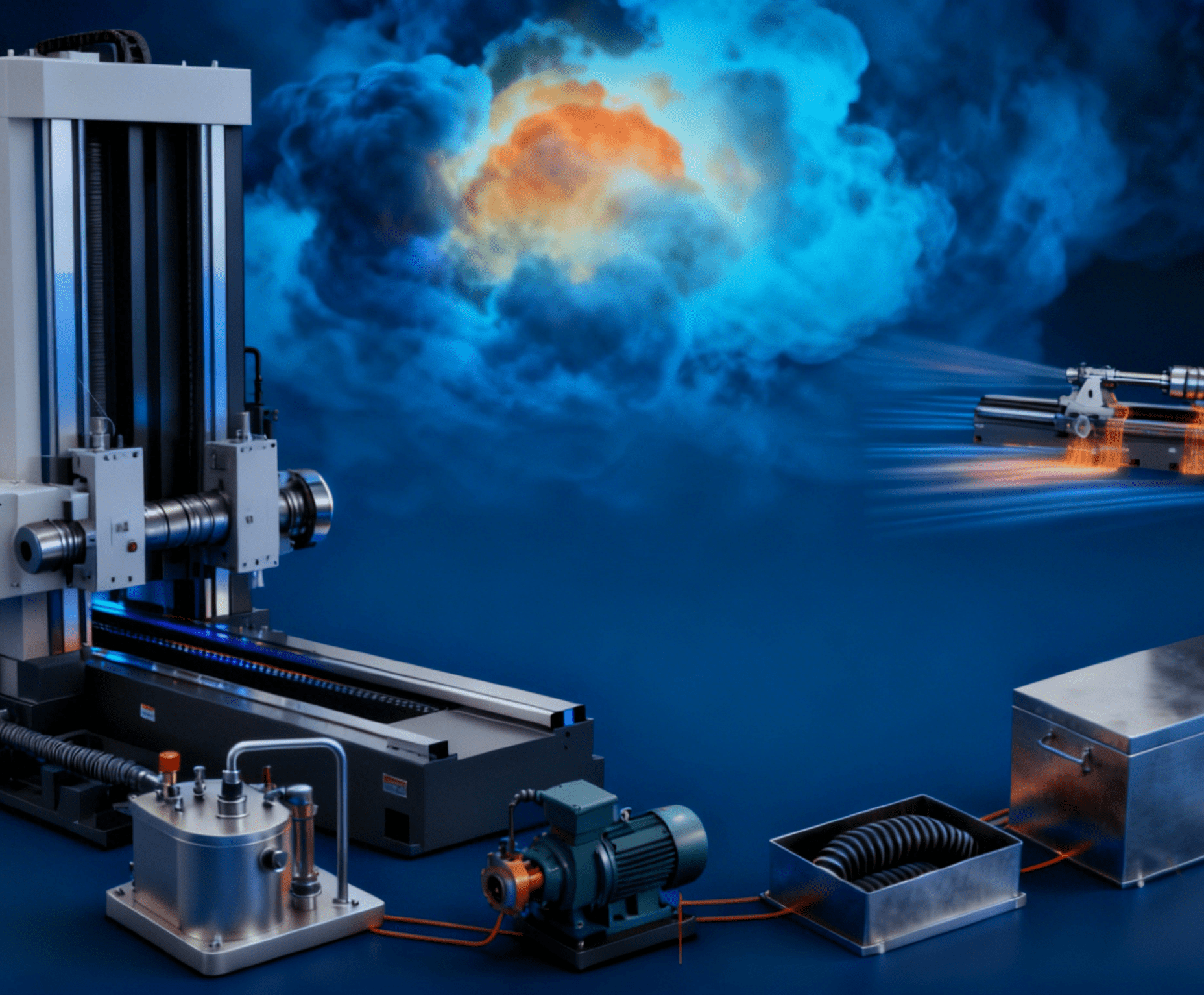

Green Machining Technology Breakthroughs: Pressures to reduce pollution have spurred the development and adoption of technologies like dry cutting and minimal quantity lubrication. Beyond environmental benefits, these technologies enhance machining precision and tool life—for instance, dry cutting eliminates surface quality issues caused by cutting fluids, offering unique advantages in precision component manufacturing.

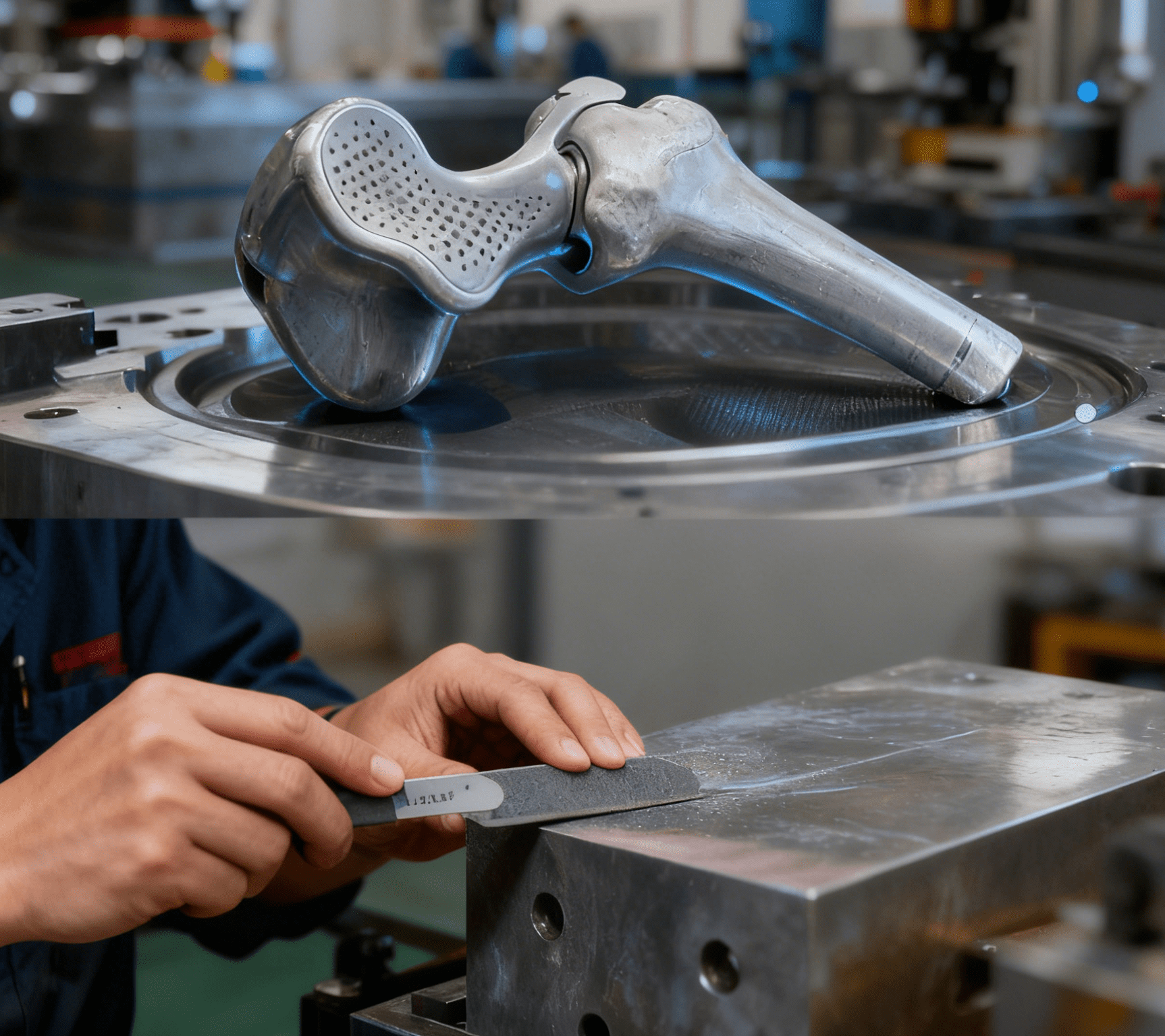

Innovative Material Applications: To minimize metal waste, enterprises are exploring more machinable and recyclable new materials, as well as material modification technologies. This has fostered collaboration between materials scientists and CNC machining firms, driving interdisciplinary innovation.

Energy-Saving Equipment Upgrades: Environmental demands have accelerated the development of energy-efficient motors and optimized machine tool power management systems. These innovations reduce operational costs, align with global sustainability trends, and boost enterprises’ market competitiveness.

Eco-Friendly Automation Integration: Environmental requirements have also promoted the iterative upgrading of robotic small product tray loading systems—key automation equipment in post-machining sorting and packaging. Equipped with energy-saving servo motors and intelligent material identification algorithms, these systems minimize idle energy consumption during the tray loading process and accurately classify small precision components by size and material, improving the recycling rate of leftover materials and reducing resource waste. For example, in the production of micro-precision parts, the system’s precise positioning and gentle clamping avoid component damage, reducing scrap rates by over 10% while cutting overall production line energy consumption. This integration of automation and environmental protection not only meets strict emission and resource utilization standards but also enhances production continuity, becoming a typical case of green innovation in the industry.

Synergistic Development: From Compliance Pressure to Sustainable Innovation

In summary, while environmental requirements may bring short-term financial and operational pressures to enterprises, they are by no means a barrier to long-term innovative development. Instead, they push enterprises to break free from traditional mindsets, explore green, efficient, and sustainable machining models, and achieve coordinated progress between environmental protection and innovation.

This shift not only addresses ecological concerns but also lays a solid foundation for the industry’s transformation, upgrading, and sustainable growth—proving that environmental compliance and innovation are not mutually exclusive, but rather complementary drivers of long-term success.