In fields such as precision mechanical machining, CNC precision machining, and medical component machining, surface roughness is one of the key indicators for measuring product quality. A smooth surface can not only improve the aesthetics of a product but, more importantly, enhance its performance and service life. So, how to effectively optimize surface roughness in precision machining?

Rational Selection of Cutting Parameters

Cutting parameters have a direct impact on surface roughness. Cutting speed is the primary factor to consider. In CNC machining, appropriately increasing the cutting speed can reduce fluctuations in cutting force, thereby lowering surface roughness. For example, when machining aluminum alloy parts, a higher cutting speed allows chips to be discharged more smoothly, preventing chips from causing scratches on the machined surface. However, a higher cutting speed is not always better; an excessively high speed may accelerate tool wear, which in turn affects surface quality.

Feed rate is also a key parameter. A smaller feed rate enables the tool to leave finer cutting marks on the workpiece surface, thereby reducing surface roughness. Nevertheless, an overly small feed rate will decrease machining efficiency, so a balance must be struck between the two. The depth of cut should not be overlooked either; a suitable depth of cut can ensure the stability of the cutting process and avoid the deterioration of surface roughness caused by excessive cutting force.

Optimization of Tool Selection and Usage

The selection and usage of tools are crucial for surface roughness. The performance of tool materials, such as hardness, wear resistance, and heat resistance, directly affects the cutting effect. In mold machining, using cemented carbide tools or ceramic tools—compared to ordinary high-speed steel tools—can maintain sharpness at higher cutting speeds, reduce tool wear, and thus achieve better surface quality.

The geometric shape of the tool should also not be ignored. Parameters such as the tool’s rake angle, relief angle, and inclination angle affect the distribution of cutting force and the formation of chips. A reasonable design of the tool’s geometric shape can make the cutting process more stable and reduce surface roughness. In addition, regularly inspecting and replacing tools to ensure they are always in good cutting condition is also an important measure to optimize surface roughness.

Improving the Stability of the Machining Process System

The stability of the machining process system is the foundation for ensuring surface quality. In Dongguan CNC machining, the accuracy and rigidity of the machine tool have a significant impact on surface roughness. A high-precision and high-rigidity machine tool can reduce vibration and deformation during the machining process, thereby lowering surface roughness. Regular maintenance and calibration of the machine tool are necessary to ensure that all its performance indicators meet the requirements.

The workpiece clamping method also affects machining stability. Selecting appropriate fixtures and clamping methods to ensure the workpiece is firm and reliable during machining can prevent vibration caused by workpiece loosening, which would otherwise affect surface quality. At the same time, rationally arranging the machining sequence to reduce stress concentration during the machining process also helps improve the stability of the machining process system.

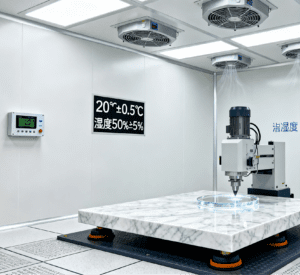

Controlling the Machining Environment

The machining environment also has a certain impact on surface roughness. Changes in temperature and humidity may cause thermal expansion and contraction of the workpiece and tool, affecting machining accuracy and surface quality. During precision machining, maintaining stable temperature and humidity in the machining environment can reduce machining errors caused by environmental factors. In addition, reducing dust and impurities at the machining site and preventing them from entering the machining area also plays a positive role in optimizing surface roughness.

For small precision parts (such as micro-medical components or precision sensor elements) with strictly controlled surface roughness, the Robotic Small Product Tray Loading System is widely used in post-machining handling. This system uses programmable robotic arms for gentle clamping and precise tray placement, avoiding surface scratches or contamination caused by manual handling, and effectively preserving the optimized low-roughness surface state of the parts.

In precision machining, by rationally selecting cutting parameters, optimizing tool selection and usage…