Among the various types of intelligent machining, precision CNC broaching occupies an important position due to its unique processing method and excellent machining accuracy.

Application Scenarios: High-Precision Demands in Key Industries

Precision CNC broaching is mainly applied in the machining of parts that have extremely high requirements for shape accuracy and surface quality. In the automotive manufacturing industry, key engine components such as valve guides and spline shafts often adopt the precision CNC broaching process. Valve guides require high-precision inner hole shapes and extremely smooth inner surfaces to ensure the smooth operation of valves. Precision CNC broaching can machine the inner hole to the required dimensional accuracy and surface roughness in one go, greatly improving production efficiency and product quality. In the aerospace field, for the machining of tenon grooves at the root of aero-engine blades with complex shapes, precision CNC broaching also demonstrates irreplaceable advantages. It can accurately shape complex tenon groove contours in accordance with design requirements, meeting the strict reliability requirements for components under extreme working conditions such as high temperature, high pressure, and high speed in aero-engines.

Core Technical Pillars: Broach Design & CNC System Control

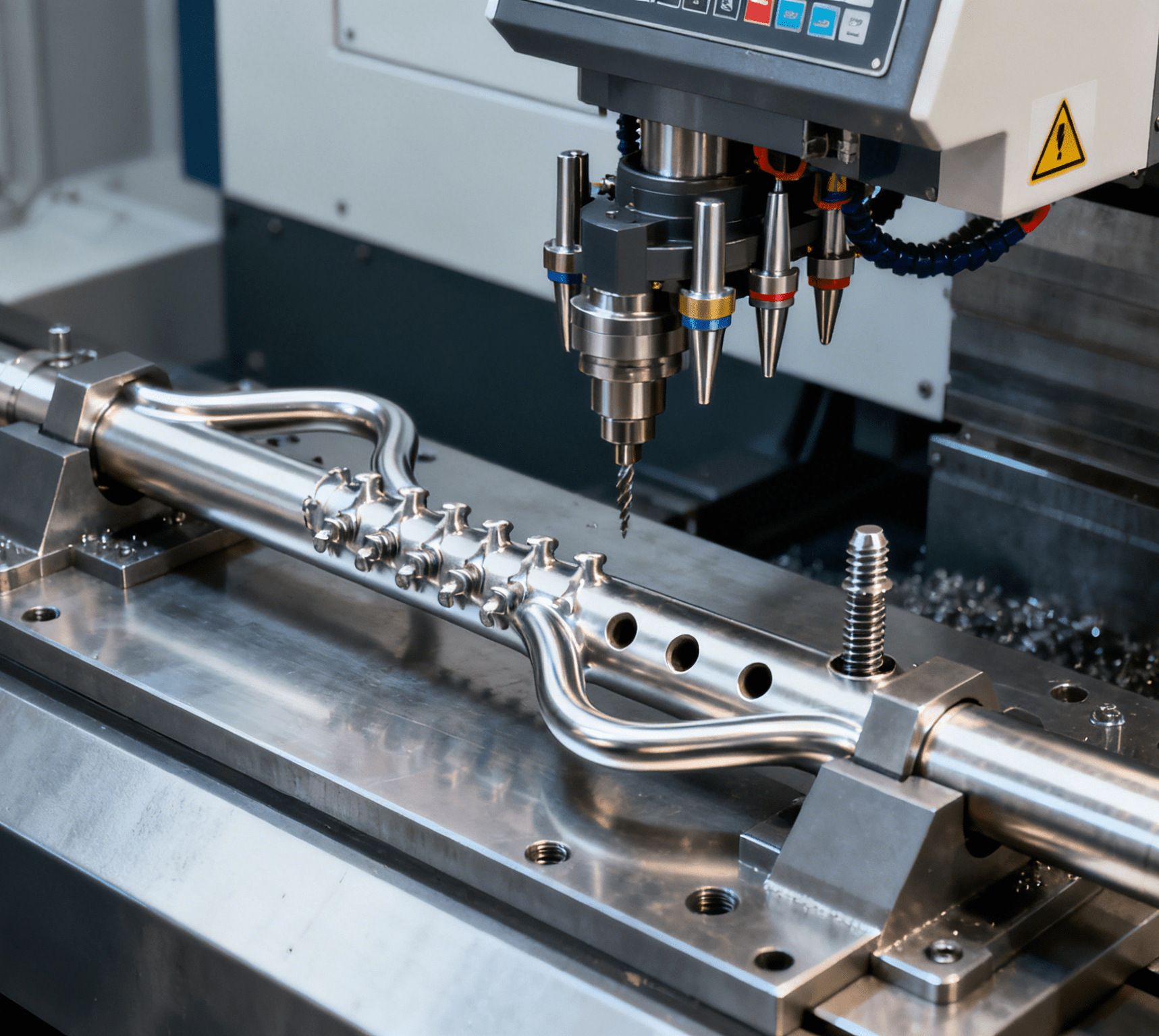

There are many technical key points in precision CNC broaching. The first is the design and manufacturing of broaches. As the core tool for precision CNC broaching, broaches have a complex structure and extremely high precision requirements. The tooth profile of a broach needs to be specially designed according to the shape of the part to be machined, and parameters such as the cutting angle and tooth lift of each tooth are accurately calculated. For example, when machining internal splines, the tooth profile of the broach must perfectly match the tooth groove shape of the spline to achieve efficient and precise cutting. At the same time, the material selection of broaches is also crucial. High-performance high-speed steel or cemented carbide materials are usually used to ensure sufficient hardness, wear resistance, and toughness, enabling them to withstand the huge cutting forces and frictional forces during the broaching process.

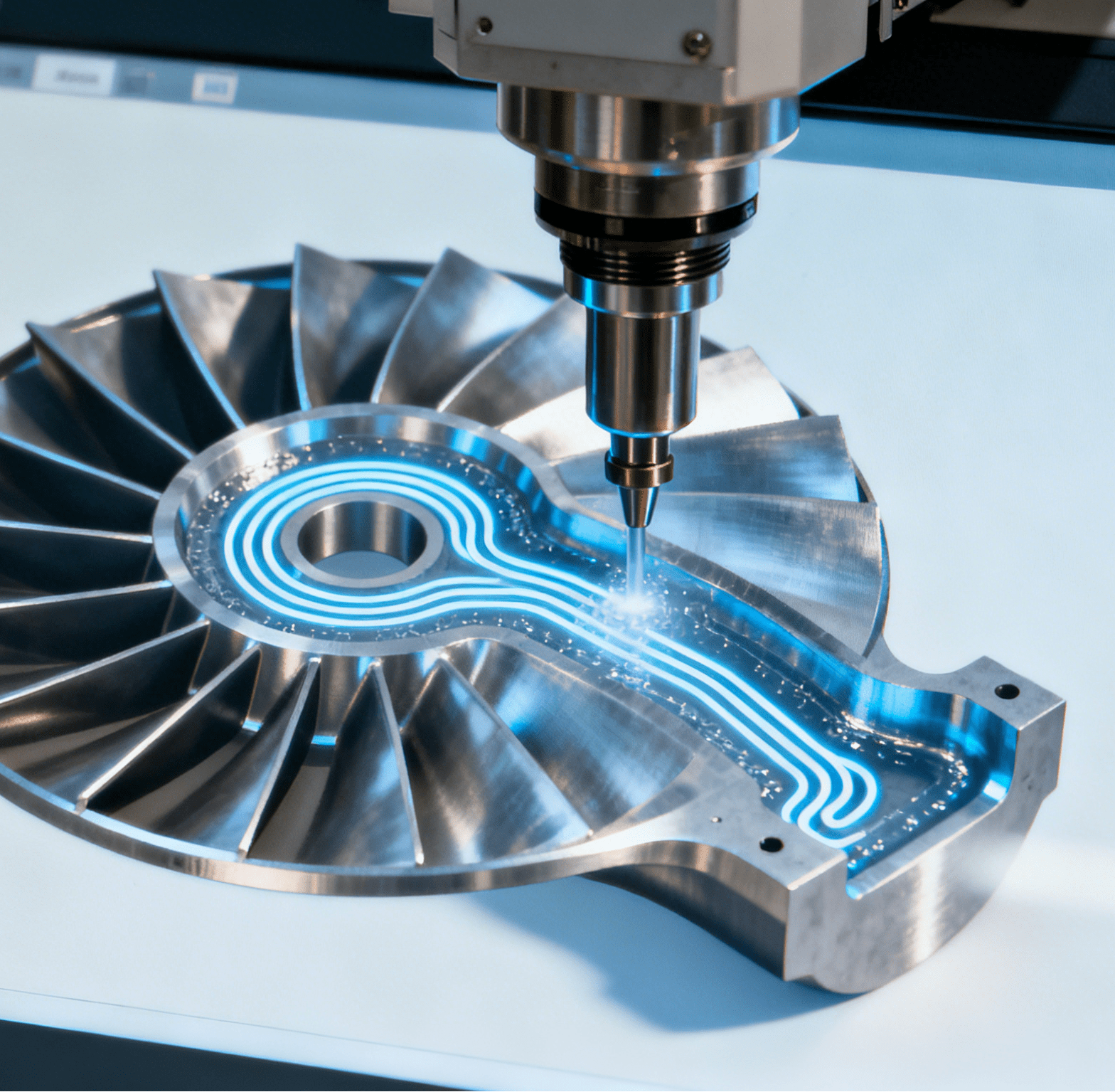

The CNC system plays a key control role in precision CNC broaching. It can accurately control parameters such as the movement trajectory, cutting speed, and feed rate of the broach. During the machining process, the CNC system adjusts the position and movement state of the broach in real time according to the pre-written program. For instance, when encountering uneven material hardness, the CNC system can automatically reduce the cutting speed or adjust the feed rate to avoid excessive wear of the broach or a decrease in machining accuracy. Moreover, advanced CNC systems are also equipped with tool monitoring functions, which can monitor the wear status of the broach in real time. Once the broach wear exceeds the set range, it promptly reminds the operator to replace or adjust it.

Supporting Systems & Machine Tool Requirements: Guaranteeing Stability and Precision

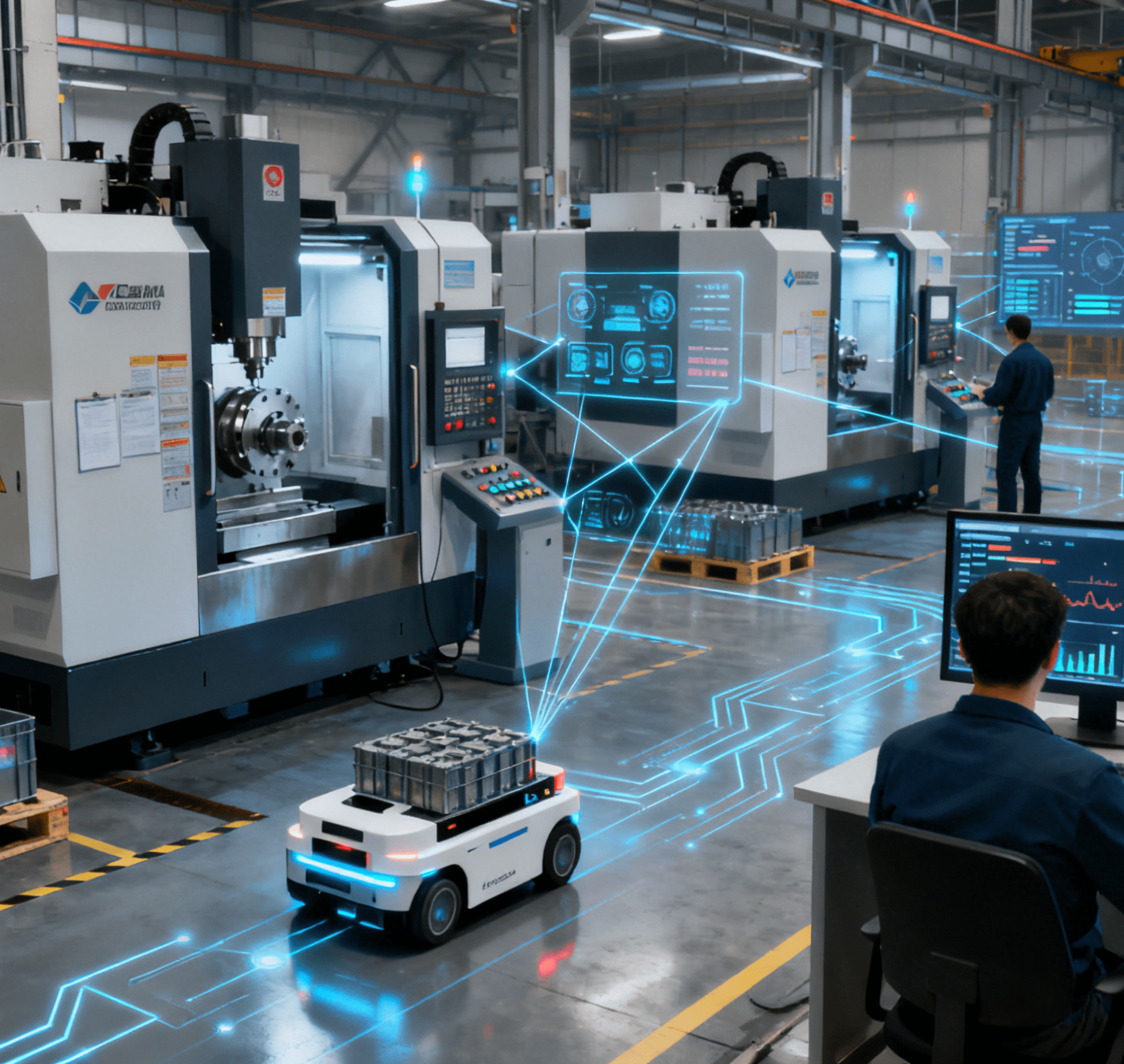

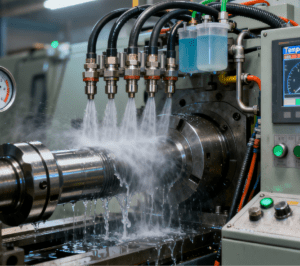

The cooling and lubrication system is also an indispensable part of precision CNC broaching. A large amount of heat and chips are generated during the broaching process. If cooling and lubrication cannot be carried out in a timely and effective manner, problems such as rapid wear of the broach, degradation of machining surface quality, and thermal deformation of parts will occur. Special cutting fluid is usually used, and through reasonably designed cooling and lubrication channels, the cutting fluid is accurately sprayed to the cutting area. The cutting fluid not only can take away heat but also plays a lubricating role, reducing the friction coefficient between the broach and the workpiece, decreasing the cutting force, and thereby further improving machining accuracy and surface quality. In addition, Sheet automatic loading robots are widely used in the automated production line of precision CNC broaching; these robots can realize automatic grabbing, conveying and positioning of sheet workpieces, ensuring that the workpieces are accurately fed into the machining position, reducing manual intervention errors, and matching the high-precision requirements of broaching while improving the continuity and efficiency of the production line.

In addition, precision CNC broaching has high requirements for the accuracy and stability of machine tools. The machine tool bed needs to have sufficient rigidity to resist the cutting force during the broaching process and prevent the machine tool from vibrating and deforming. The positioning accuracy and repeat positioning accuracy of the workbench must meet extremely high standards to ensure the positional accuracy of the workpiece during the broaching process.

As a type of intelligent machining, precision CNC broaching plays an irreplaceable role in specific application scenarios. Its technical key points cover multiple aspects such as broaches, CNC systems, cooling and lubrication systems, and machine tool accuracy. All links cooperate and interact with each other to jointly achieve high-precision and high-efficiency part machining, providing strong technical support for the development of many high-end manufacturing industries such as automotive and aerospace.

Robots realize the automated assembly of automotive connectors