Table of Contents

ToggleEpson Pioneers Collaborative Robotics: Merging Precision with Intelligent Automation

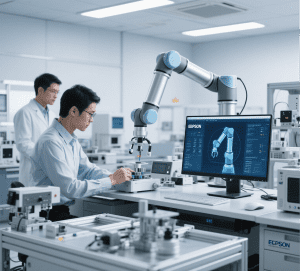

TOKYO, Japan—Seiko Epson Corporation (“Epson”) is set to redefine industrial collaboration with its first-ever collaborative robot, scheduled for launch in 2025. Built on the pillars of intelligent automation and four decades of robotics expertise, this solution aims to address labor shortages and precision demands across manufacturing, logistics, and the highly regulated life sciences and pharmaceutical sectors. By combining Epson’s legacy in industrial automation with cutting-edge design, the robot embodies the company’s vision of versatile, task-specific automation equipment that adapts to evolving industry needs. Initial deployments in Japan and Europe will pave the way for a global rollout, signaling a new era of human-robot collaboration.

Bridging Labor Gaps and Precision Demands

The manufacturing sector’s growing skilled labor shortage and the life sciences industry’s rigorous hygiene and reproducibility requirements have intensified the need for advanced automation. Epson’s collaborative robot rises to these challenges by delivering safe, clean, and efficient operations in environments where human error or contamination risks are critical. For instance, in pharmaceutical labs, the robot can handle delicate reagent transfers or sterile packaging with unmatched precision, while in manufacturing, it complements human workers on assembly lines, freeing them for higher-value tasks.

“Our goal is to create automation equipment that doesn’t just replace labor but enhances human capabilities,” says a senior Epson engineer. “By integrating intelligent automation into collaborative workflows, we’re enabling industries to achieve new levels of productivity without compromising on quality or safety.”

Engineering Excellence: Key Features for Diverse Applications

Epson’s collaborative robot is a testament to innovative design, blending lightweight agility with industrial robustness:

- Optimized Robot Arm: With a 6kg payload capacity and 900mm arm reach, the 17kg robot arm offers industry-leading mobility. Its compact size (ideal for space-constrained labs or production lines) and easy reconfiguration make it suitable for dynamic environments, from pharmaceutical R&D to small-batch manufacturing.

- Mobile-Ready Controller: The 6kg controller, designed for AGVs and AMRs, enables seamless integration with mobile robotics, transforming static automation into adaptive, factory-wide solutions.

- Universal Power Compatibility: Supporting 100–230 VAC and 48VDC inputs, the robot adapts to global power standards, ensuring hassle-free deployment across regions.

- Cleanroom Compliance: Engineered for ISO 14644-1 Class 5 cleanrooms and IP54 protection, its smooth, screwless chassis minimizes dust accumulation, making it indispensable for sterile pharmaceutical and biotech applications.

- Python Programming: By supporting Python—a lingua franca in robotics and data science—the robot reduces adoption barriers, allowing R&D teams and integrators to customize workflows without mastering niche languages.

A Catalyst for Industry 4.0 Innovation

The launch underscores Epson’s commitment to driving industrial automation forward by addressing unmet needs in emerging sectors. In life sciences, where manual pipetting or sample handling risks contamination, the robot’s precision and hygiene features could revolutionize laboratory automation. In manufacturing, its ability to work alongside humans in shared spaces (e.g., quality inspection, assembly) exemplifies the “cobotic” trend toward collaborative, 而非 replacement, automation.

“Collaborative robots are not just tools; they’re enablers of smarter, more sustainable operations,” notes Epson’s robotics division head. “By combining our expertise in precision mechanics with AI and machine learning, we’re creating automation equipment that evolves with industry demands—whether optimizing a pharmaceutical production line or enhancing a logistics warehouse’s throughput.”

Conclusion: Shaping the Future of Collaborative Automation

Epson’s foray into collaborative robotics marks a pivotal step in the fusion of intelligent automation and human ingenuity. As industries grapple with labor challenges and the need for scalable solutions, this robot emerges as a versatile partner—capable of elevating precision in life sciences, streamlining workflows in manufacturing, and driving efficiency in logistics.

With its 2025 launch, Epson isn’t just introducing a product; it’s laying the groundwork for a new paradigm in industrial automation, where robots enhance human potential, rather than replace it. As the company expands its automation portfolio, the collaborative robot serves as a blueprint for how automation equipment can drive innovation across sectors—proving that the future of work is not about machines versus humans, but machines working with humans to achieve unprecedented heights.