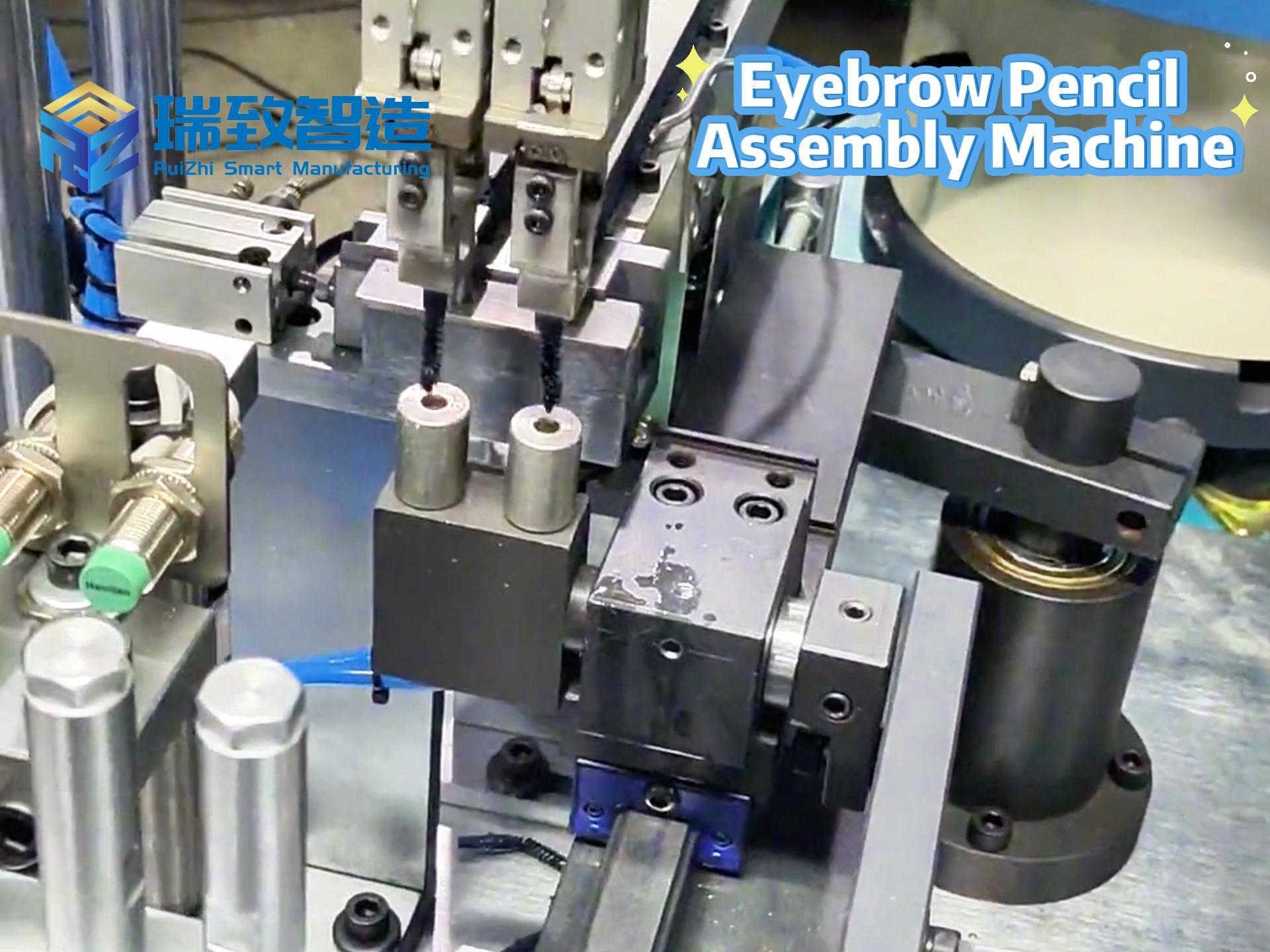

As the automotive industry accelerates toward electrification and intelligence, automotive quick-connect parts—critical components for fluid and electrical transmission in engines, thermal management systems, and charging modules—demand higher assembly precision and flexibility. However, traditional standard assembly equipment struggles to meet the diverse needs of multi-model production, strict leak-proof requirements, and efficient line changeover in automotive manufacturing. Ruizhi Intelligent Manufacturing specializes in customized non-standard automation solutions for automotive quick-connect parts assembly, effectively addressing industry pain points and empowering manufacturers to enhance production efficiency and quality.

Key Challenges in Automotive Quick-Connect Parts Assembly

Automotive quick-connect parts assembly faces unique industry challenges. Firstly, multi-model compatibility: With the proliferation of new energy vehicles and traditional fuel vehicles, manufacturers need to produce dozens of quick-connect models for different systems, requiring frequent equipment retooling which causes long downtime. Secondly, strict leak-proof standards: Fluid and electrical quick-connects must ensure zero leakage to avoid safety hazards such as battery short circuits or engine overheating, demanding sub-millimeter assembly precision. Thirdly, ergonomic and efficiency issues: Manual assembly is labor-intensive, prone to errors, and cannot keep up with the high-volume production demands of modern automotive factories. These challenges make non-standard automated assembly solutions a necessary choice for industry upgrading.

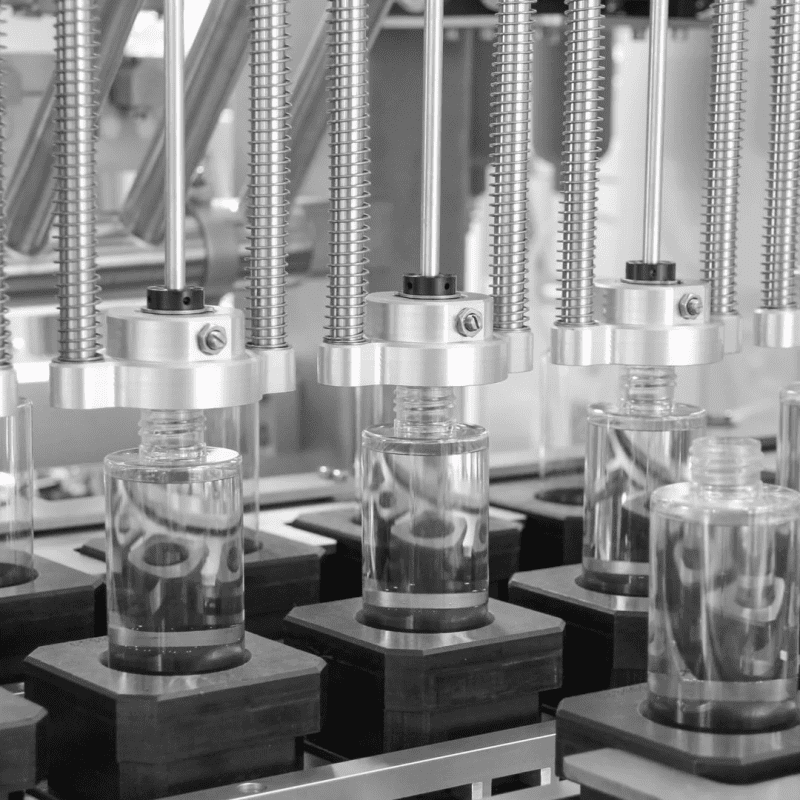

Core Advantages of Ruizhi’s Non-Standard Automation Solutions

Ruizhi Intelligent Manufacturing’s non-standard automation solutions for automotive quick-connect parts assembly stand out with three core advantages. First, modular design for flexible production: The system adopts a modular structure that supports quick switching between 8-12 quick-connect models within 6 minutes, reducing line changeover time by over 75% compared to traditional equipment. Second, intelligent leak-proof inspection: Equipped with high-precision machine vision and air-tightness testing modules, the system automatically detects fitting gaps, sealing ring installation, and connection tightness, controlling the defect rate to less than 0.02%. Third, seamless integration capability: Customized according to the customer’s on-site layout and production process, the solution can seamlessly connect with upstream material feeding and downstream testing processes, improving overall line efficiency by 30-50%.

Case Study: Ruizhi’s Solution Transforms EV Quick-Connect Production

A leading EV component manufacturer in Zhejiang specialized in producing high-voltage fluid quick-connects for battery thermal management systems. The customer faced severe challenges: frequent model changes (6 models in total) led to 40-minute retooling downtime per change; manual assembly resulted in a 1.5% defect rate due to inconsistent sealing; and low efficiency (400 units/hour) failed to meet market demand. After in-depth on-site investigation, Ruizhi Intelligent Manufacturing customized a fully automatic non-standard assembly line for the customer.

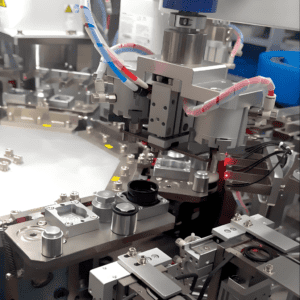

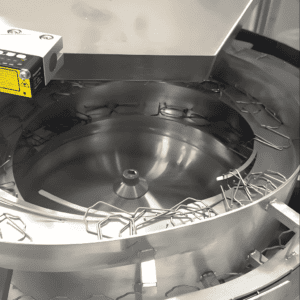

The solution integrated modular fixtures, automatic feeding mechanisms, and intelligent leak-testing stations. It supported automatic switching between 6 quick-connect models and adopted precision pressure sensors to ensure stable connection force. After implementation, the customer’s production efficiency increased to 1300 units/hour (a 225% improvement), retooling time was shortened to 5 minutes, and the defect rate dropped to 0.005%. Annual labor costs were reduced by 55%, and the stable product quality helped the customer win long-term cooperation with major EV OEMs.

Ruizhi Intelligent Manufacturing has rich experience in the automotive automation field, with a professional team providing one-stop services from demand analysis, program design, equipment manufacturing to on-site commissioning. We closely follow automotive industry trends, continuously integrate advanced technologies such as IoT and digital twins into solutions, and help customers achieve intelligent production upgrading.

If you are facing challenges in automotive quick-connect parts assembly such as inflexible production, low precision, or inefficient line changeover, contact Ruizhi Intelligent Manufacturing today to get a customized non-standard automation solution and empower your high-quality production.

Examples of Robot Automatic Assembly Lines

Advantages of Artificial Intelligence Automatic Assembly Lines