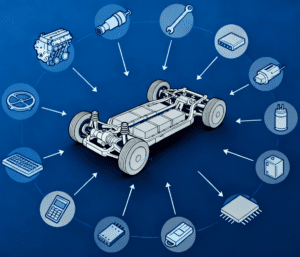

With the rise of smart manufacturing, exploring and applying automation has become an inevitable path for progress in the automotive industry. Enterprises often prioritize investing in advanced automated equipment, upgrading machinery to stay ahead of competitors in the era of transformation and innovation. However, due to the unique characteristics of automotive final assembly processes, the automation rate in final assembly across the industry remains around 12%—in stark contrast to stamping, welding, and painting processes, where automation rates exceed 80% thanks to declining robot costs and widespread adoption of vision systems in recent years. The key challenge now is: How to reasonably drive final assembly automation to reduce manufacturing costs, stabilize product quality, and enhance overall competitiveness?

Current Status of Automotive Final Assembly Automation in China

Complexity of Component Assembly

Automotive final assembly involves integrating thousands of parts, each with distinct structures and installation positions. This complexity makes it difficult for automated equipment to fully replace manual work—one reason why final assembly automation lags behind welding and painting. In most cases, automated systems cannot match the flexibility of human hands and eyes in precision control and inspection, struggling to ensure stable production and quality. This challenge is amplified in high-mix, flexible, and high-tempo production lines, where achieving full automation is particularly arduous.

Limitations of Existing Production Lines

Final assembly lines are generally more flexible than welding fixtures. As long as overall dimensions allow for smooth conveying and production capacity meets demand, enterprises rarely build new final assembly lines. However, existing lines often lack the precision to match component movement, making retrofitting for automation difficult. Dynamic 随行自动化 (dynamic 随行自动化: dynamic synchronous automation) imposes strict requirements on equipment design, machining, installation, and component tolerances—so most automated assembly processes today are prioritized for static workstations. Retrofitting existing dynamic lines into segmented static stations would require adding stop positions and transition sections, occupying more mainline workstations, incurring high costs, and extending downtime—all of which conflict with mass production schedules.

Skill Gaps in Maintenance

Automated equipment demands skilled maintenance personnel, particularly those with expertise in robotics, vision systems, and electrical control. Many automotive enterprises currently lack such talent reserves, and even trained technicians are prone to turnover. This leads to delayed responses to equipment failures, reducing mean time between failures (MTBF) and prolonging mean time to repair (MTTR), ultimately hampering production efficiency.

How Smart Retrofits of Automotive Assembly Lines Enhance Efficiency and Quality

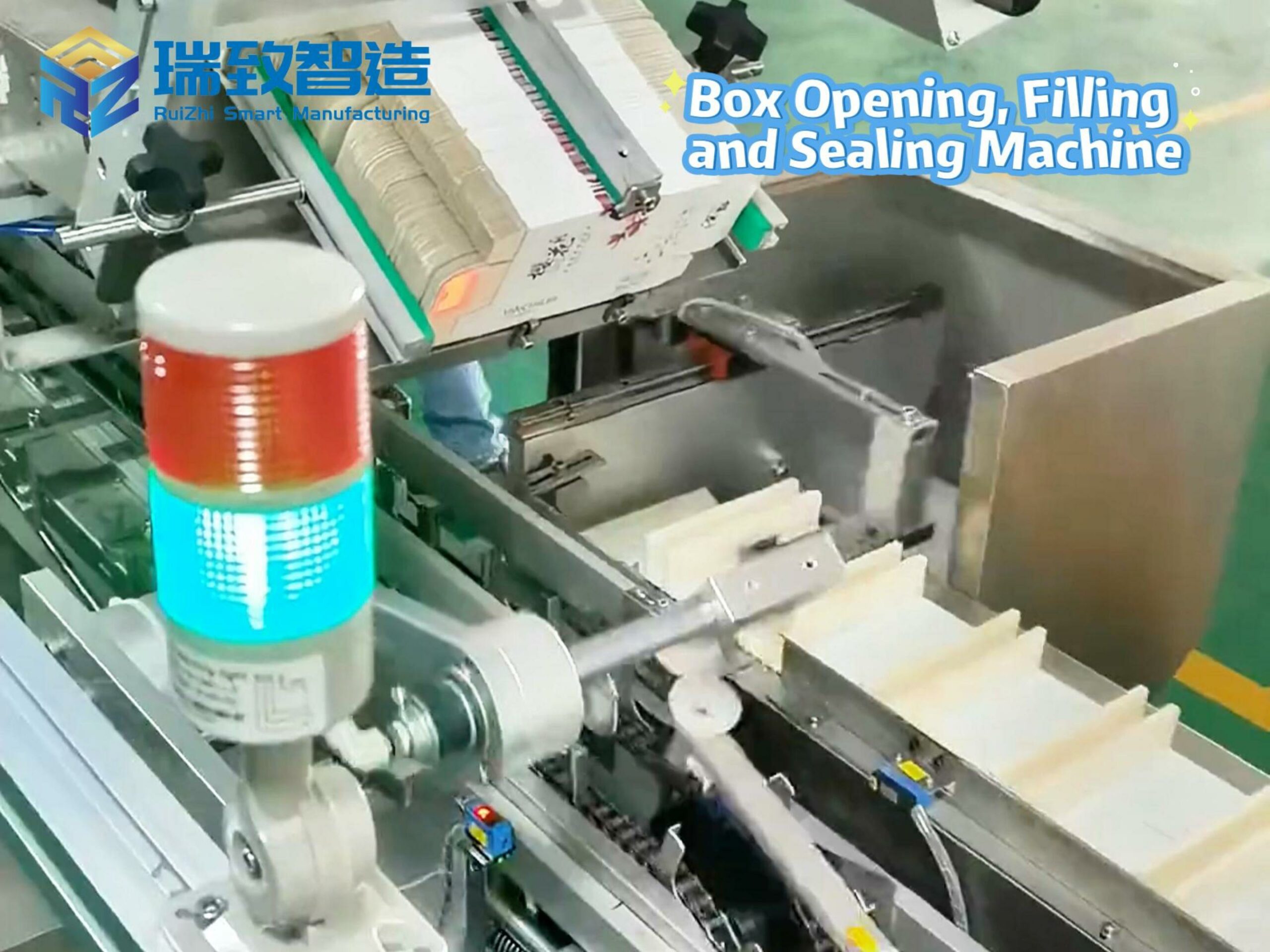

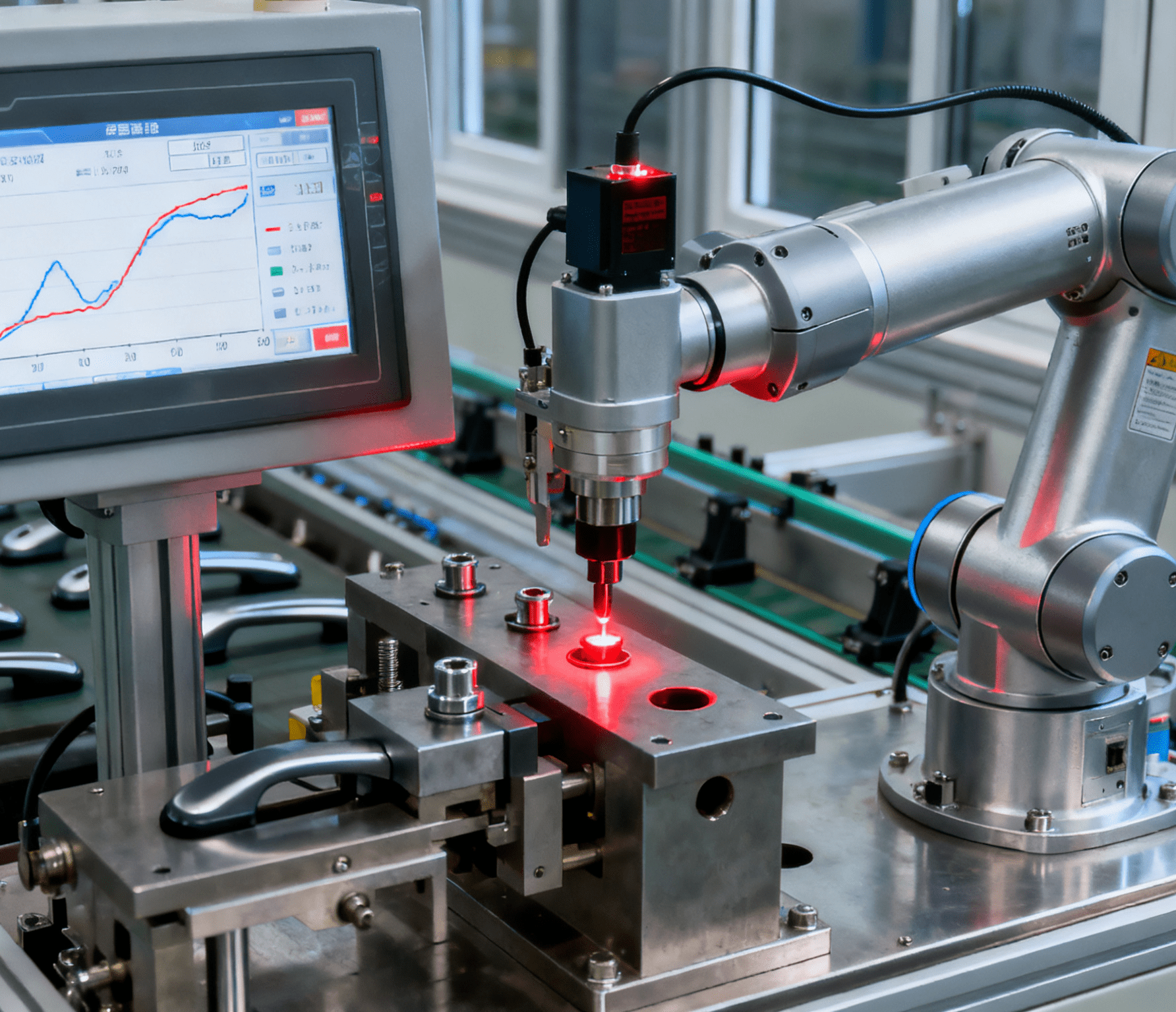

Intelligent upgrades to automotive assembly lines have delivered significant improvements in manufacturing efficiency and quality. Key automotive assembly machine applications include:

Volkswagen’s MQB Platform: Adopting modular assembly systems, the platform reduced traditional 45-minute assembly cycles to 28 minutes, cutting labor costs by 35%.

Tesla Gigafactory: Deploying 2,000 collaborative robots to automate the entire process from body welding to painting, tripling production capacity.

Toyota’s AI Vision Inspection: Integrating AI-powered vision systems reduced assembly error rates from 0.3% to 0.01% and shortened quality traceability time by 80%.

Meanwhile, the Automatic Iron Rod Loading and Unloading System has become a key supporting equipment in the component supply link of automotive assembly lines. It can automatically complete the loading, positioning, conveying and unloading of iron rod workpieces used in automotive chassis, suspension and other components, avoiding the low efficiency and high error rate of manual operation. By connecting with the assembly line’s intelligent control system, it realizes seamless docking with subsequent assembly processes, further improving the continuity and stability of the entire production line.

Results show that industry-wide production efficiency increases by 40-60%, with single-line annual capacity reaching 200,000 units and energy utilization improving by 25%. Flexible production systems now support multi-model co-line manufacturing, with model changeover times reduced from 4 hours to 15 minutes.

Future Trends: 5G + Industrial Internet Driving Evolution

As 5G and industrial internet converge, automotive assembly lines will shift toward real-time data-driven optimization. This integration will push the automotive manufacturing industry toward full-value-chain intelligence, with automotive assembly machines playing a central role in enabling faster, more flexible, and higher-quality production.

For automotive enterprises seeking to thrive in smart manufacturing, adopting advanced automotive assembly machines and automation solutions is no longer an option—it’s a necessity to stay competitive in the global market.

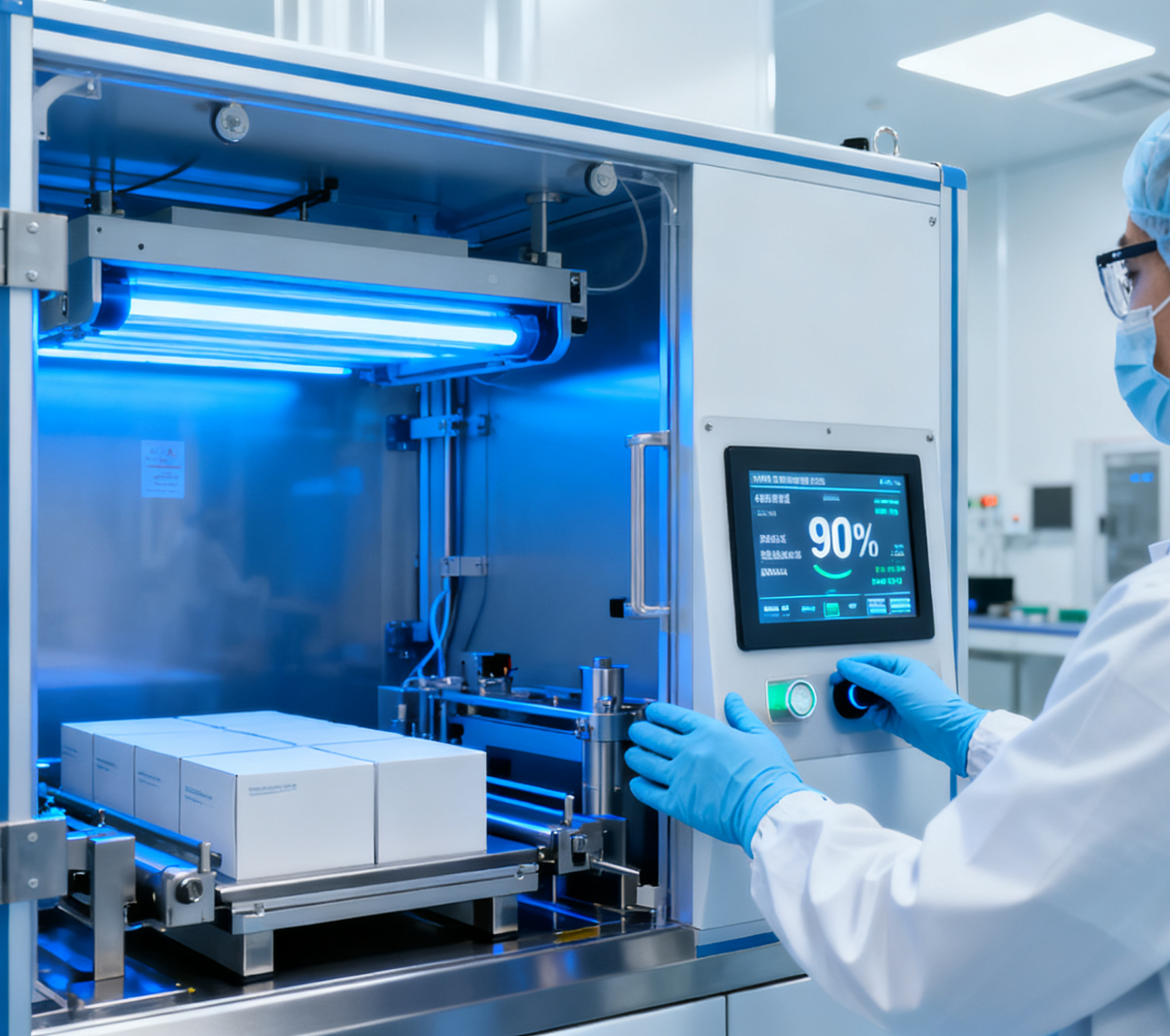

What is the market size and development trend of medical product assembly machines?

What are the advantages of medical product assembly machines?