In Today’s Rapidly Evolving Manufacturing EnvironmentTo stay ahead in the competition, it is essential to adopt cutting-edge technologies. One innovation that promises to revolutionize production lines is the automatic cap assembly machine. This advanced machinery automates the cap assembly process, providing manufacturers with unparalleled efficiency, speed, and precision. Join us as we explore this groundbreaking technology and discover how it is shaping the future of manufacturing.

Unleash Efficiency: Practical Applications of Automatic Cap Assembly Machines

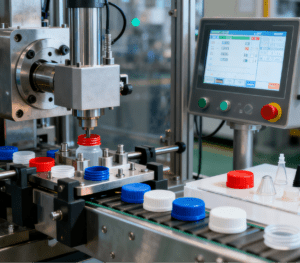

Automatic cap assembly machines leverage the power of automation to optimize production workflows. Delve into their intricate mechanisms and witness firsthand how they streamline cap assembly, maximize efficiency, and minimize human error. For caps with built-in spring structures—such as push-type cosmetic caps, medical spray caps, or leak-proof beverage bottle caps—that rely on precise spring positioning to ensure functionality (e.g., smooth pressing or sealed closure), these machines often integrate a 4 – Axis Robotic Vision – Guided Spring Placement System. The 4-axis robot, with its flexible combination of linear (X/Y/Z) and rotational motion, easily reaches narrow internal cavities of caps that manual tools struggle to access; meanwhile, the vision guidance system captures real-time high-resolution images of the cap’s internal spring slots, automatically calibrating placement deviations (up to ±0.02mm) to avoid misalignment. This system eliminates the common manual issues of spring skewing or missing placement, and cuts the spring assembly step from 8–10 seconds per cap (manual) to just 2–3 seconds, directly boosting the overall line efficiency by 30% or more.

Redefine Precision: The Accuracy of Automatic Cap Assembly Machines

Learn how automatic cap assembly machines achieve unmatched precision in cap placement, torque control, and quality assurance. Explore the advanced sensors and algorithms that ensure every cap is assembled flawlessly, meeting the highest industry standards.

Accelerate Production Speed: Boost Output with Automatic Cap Assembly Machines

Gone are the days of slow and tedious manual assembly. Dive into the impressive speed capabilities of automatic cap assembly machines and understand how they significantly increase productivity while maintaining impeccable quality.

Simplify Workflows: Integrate Automatic Cap Assembly Machines into Your Production Line

Integrating new machinery into existing workflows can be a challenge. Explore the seamless integration options offered by automatic cap assembly machines and see how they fit smoothly into your manufacturing processes to optimize overall productivity.

Flexibility and Adaptability: Customize Automatic Cap Assembly Machines to Your Needs

Every manufacturing operation is unique. Learn how automatic cap assembly machines can be customized to accommodate different cap sizes, shapes, and materials, ensuring they perfectly meet your specific requirements.

Cost Savings and ROI: Analyze the Economic Benefits of Automatic Cap Assembly Machines

Explore the economic advantages of investing in automatic cap assembly machines. From reducing labor costs to boosting productivity, understand how this technology delivers impressive returns on investment for manufacturers.

Automatic cap assembly machines represent the future of manufacturing, offering unparalleled efficiency, precision, and speed. By adopting this innovative technology, manufacturers can optimize their production lines, reduce costs, enhance quality control, and unlock new possibilities. It’s time to explore the potential of automatic cap assembly machines and discover the transformative impact they can have on your manufacturing operations.

An automatic cap assembly machine is a type of machinery used in manufacturing to automatically attach caps, lids, or closures to containers such as bottles, jars, or tubes. These machines are designed to improve the efficiency and productivity of the assembly process while reducing labor costs.

Typically, an automatic cap assembly machine consists of a conveyor system that transports containers to the assembly station, where caps are automatically positioned and attached to the containers. The machine is equipped with sensors and control systems to ensure caps are properly aligned and secured to the containers.

These machines can be customized to handle different sizes and types of caps, containers, and production volumes. Some models may include additional features, such as label applicators or quality control systems, to ensure products meet the required specifications.